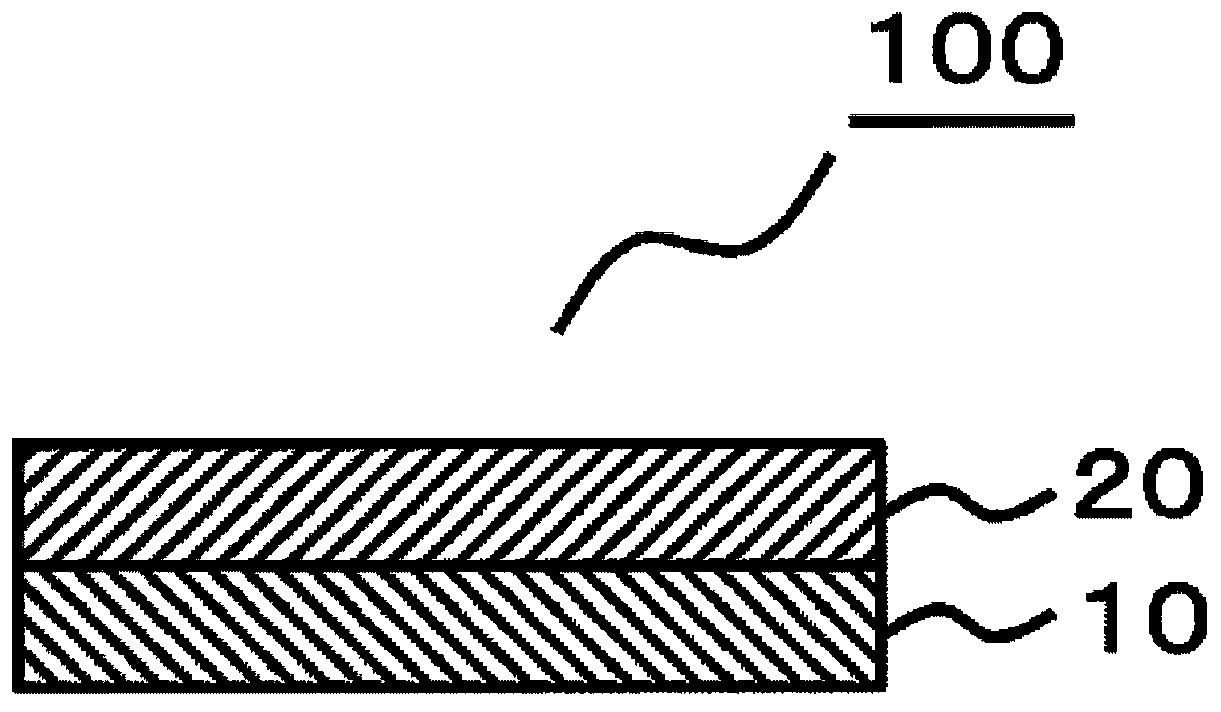

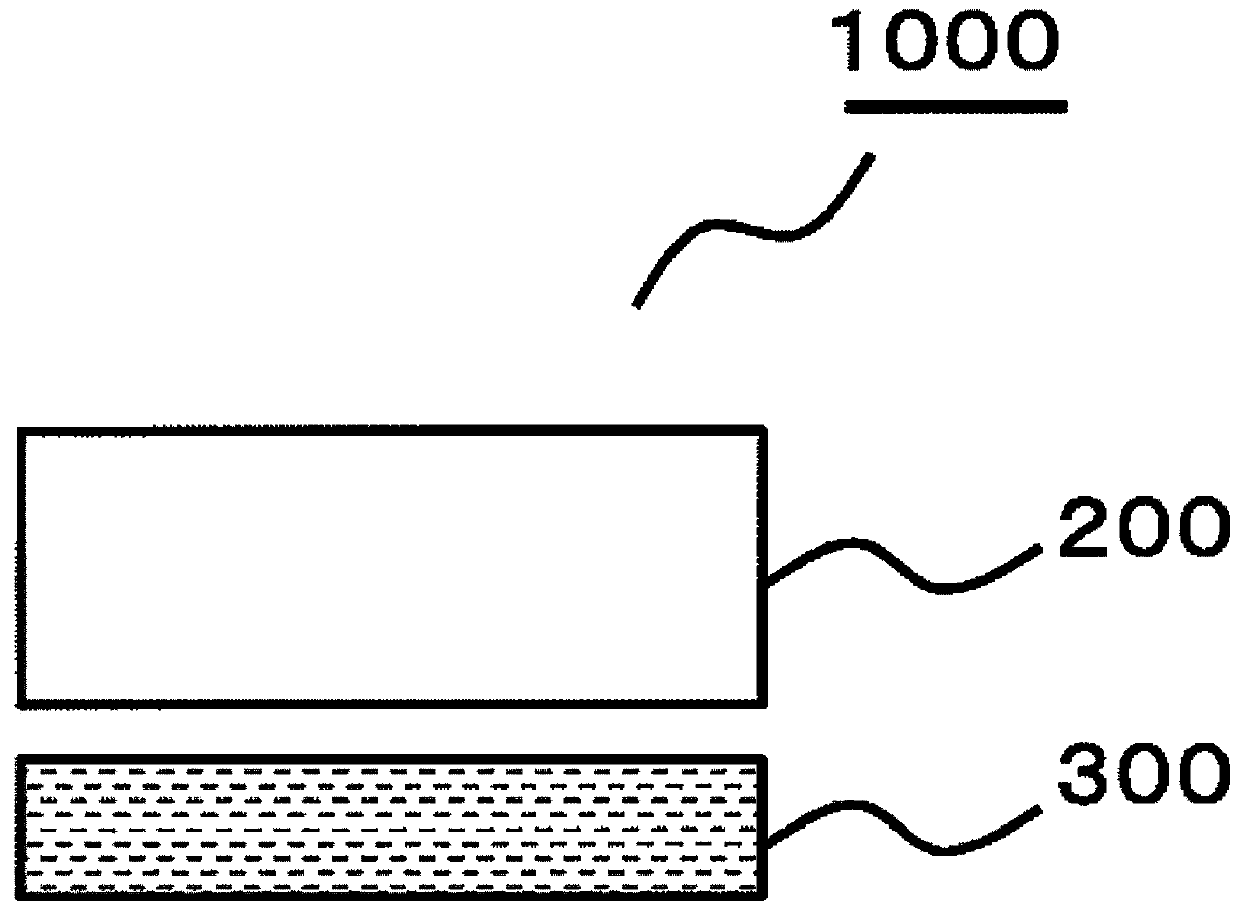

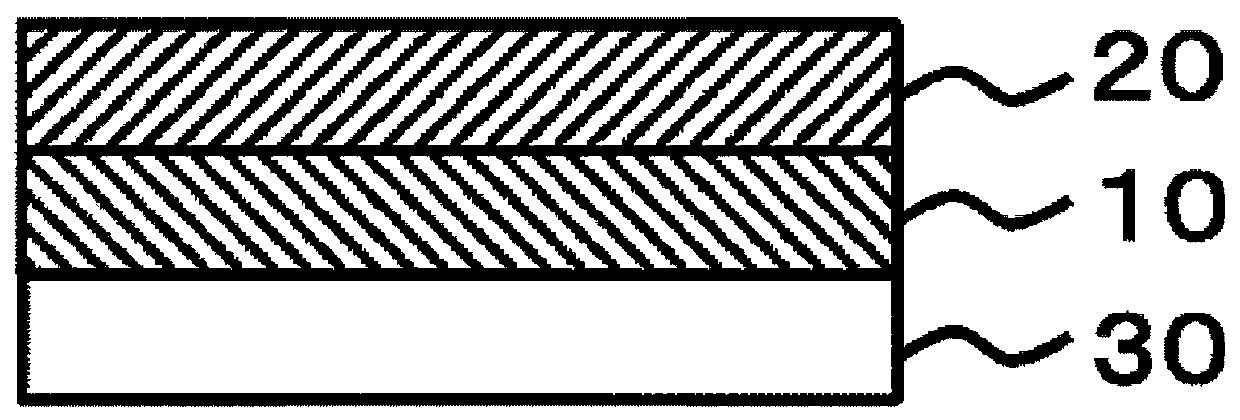

Optical laminate

A technology of optical laminates and absorbing layers, applied in optics, optical components, nonlinear optics, etc., can solve problems such as abnormal hue, high cost, and reduced brightness, and achieve sufficient brightness, suppress reflectivity, and achieve cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] (wavelength conversion layer)

[0148] A commercially available TV (manufactured by Samsung, trade name "UN65JS9000FXZA") was disassembled to obtain a quantum dot sheet which is a wavelength conversion material contained on the backlight side. This quantum dot sheet is used as the wavelength conversion layer (1).

[0149] (absorbent layer)

[0150] Contains 0.3 wt. Parts, 1 part by weight of isocyanate crosslinking agent (manufactured by Tosoh, trade name "Coronate L"), 0.3 parts by weight of pigment (manufactured by Yamada Chemical Industry Co., Ltd., trade name "FDG-007"), phenolic antioxidant ( BASF Japan company make, brand name "IRGANOX1010") 0.2 weight part, and the pigment-containing adhesive was manufactured. The pigment-containing adhesive obtained above was applied with an applicator to a thickness of 20 μm on a PET substrate (manufactured by Mitsubishi Plastics Corporation, trade name "MRF38CK") subjected to a treatment to make the adhesive easy to peel, a...

Embodiment 2

[0154] (absorbent layer)

[0155] 0.3 parts by weight of the pigment used (manufactured by Yamada Chemical Industry Co., Ltd., trade name "FDG-007") was changed to 0.3 parts by weight of pigment (manufactured by Yamada Chemical Industry Co., Ltd., trade name "FDG-004"). Otherwise, the absorbing layer (2) was formed on TAC in the same manner as in Example 1. In addition, the dye used (manufactured by Yamada Chemical Industry Co., Ltd., trade name "FDG-004") is a compound having an absorption peak at a wavelength of 600 nm.

[0156] (optical laminate)

[0157] The wavelength conversion layer (1) obtained in Example 1 and the above-mentioned absorption layer (2) were laminated to obtain an optical laminate (2) having a laminated structure of a wavelength conversion layer / absorption layer. The results are shown in Table 1.

Embodiment 3

[0159] (absorbent layer)

[0160] 0.3 parts by weight of the pigment used (manufactured by Yamada Chemical Industry Co., Ltd., trade name "FDG-007") was changed to 0.3 parts by weight of pigment (manufactured by Yamada Chemical Industry Co., Ltd., trade name "FS-1531"). Otherwise, the absorbing layer (3) was formed on TAC in the same manner as in Example 1. In addition, the dye used (manufactured by Yamada Chemical Industry Co., Ltd., trade name "FS-1531") is a compound having an absorption peak at a wavelength of 700 nm.

[0161] (optical laminate)

[0162] The wavelength conversion layer (1) obtained in Example 1 and the above-mentioned absorption layer (3) were laminated to obtain an optical laminate (3) having a laminated structure of a wavelength conversion layer / absorption layer. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com