Stewed food manufacturing equipment capable of being used for uniformly stewing food materials

A uniform, high-quality food technology, applied in the field of stewed food production equipment, can solve the problems of troublesome operation, inconvenient pick and place of stewed products, and high use limitations, and achieve the effects of simple operation, improved stewed effect, and easy pick and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

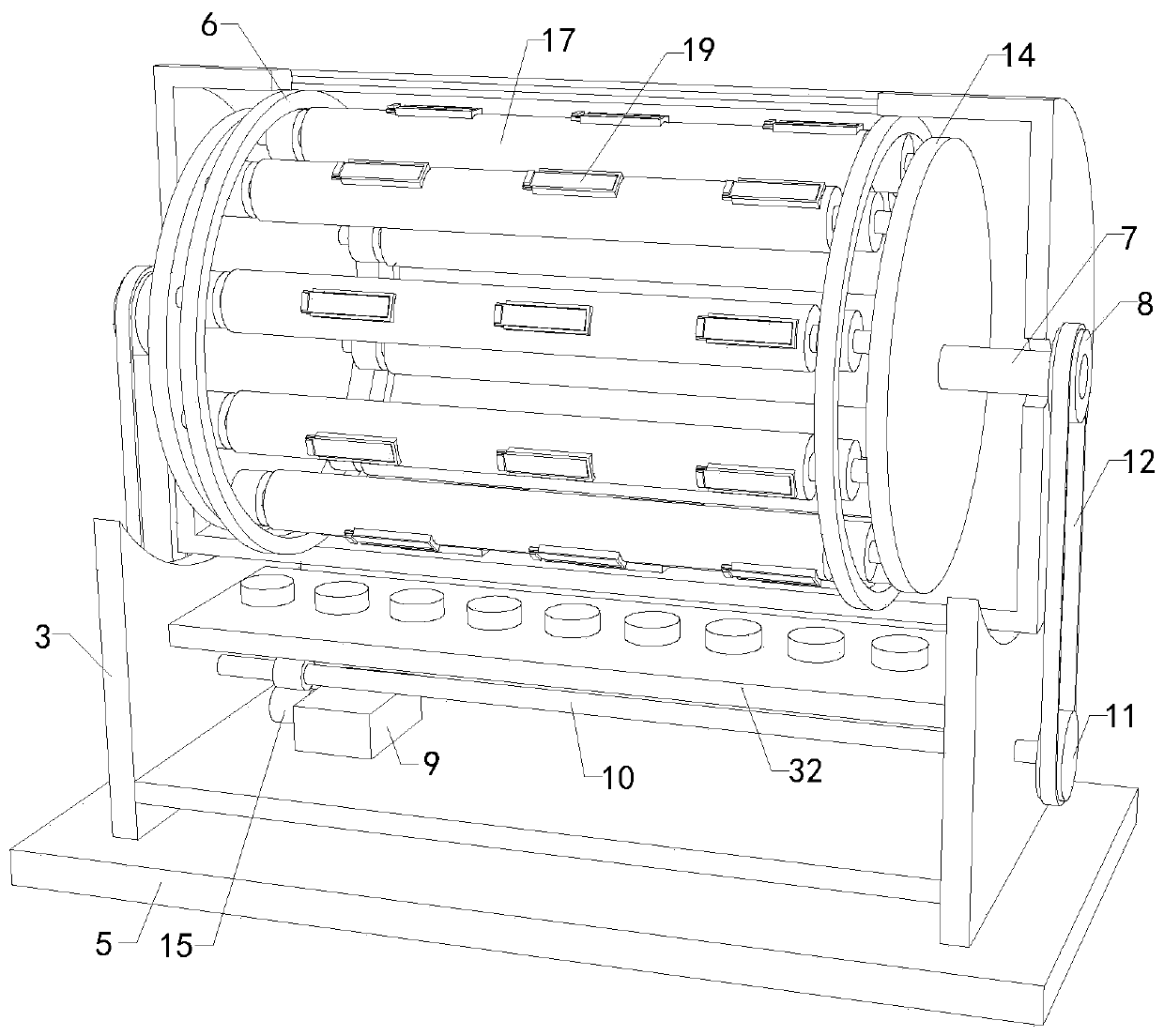

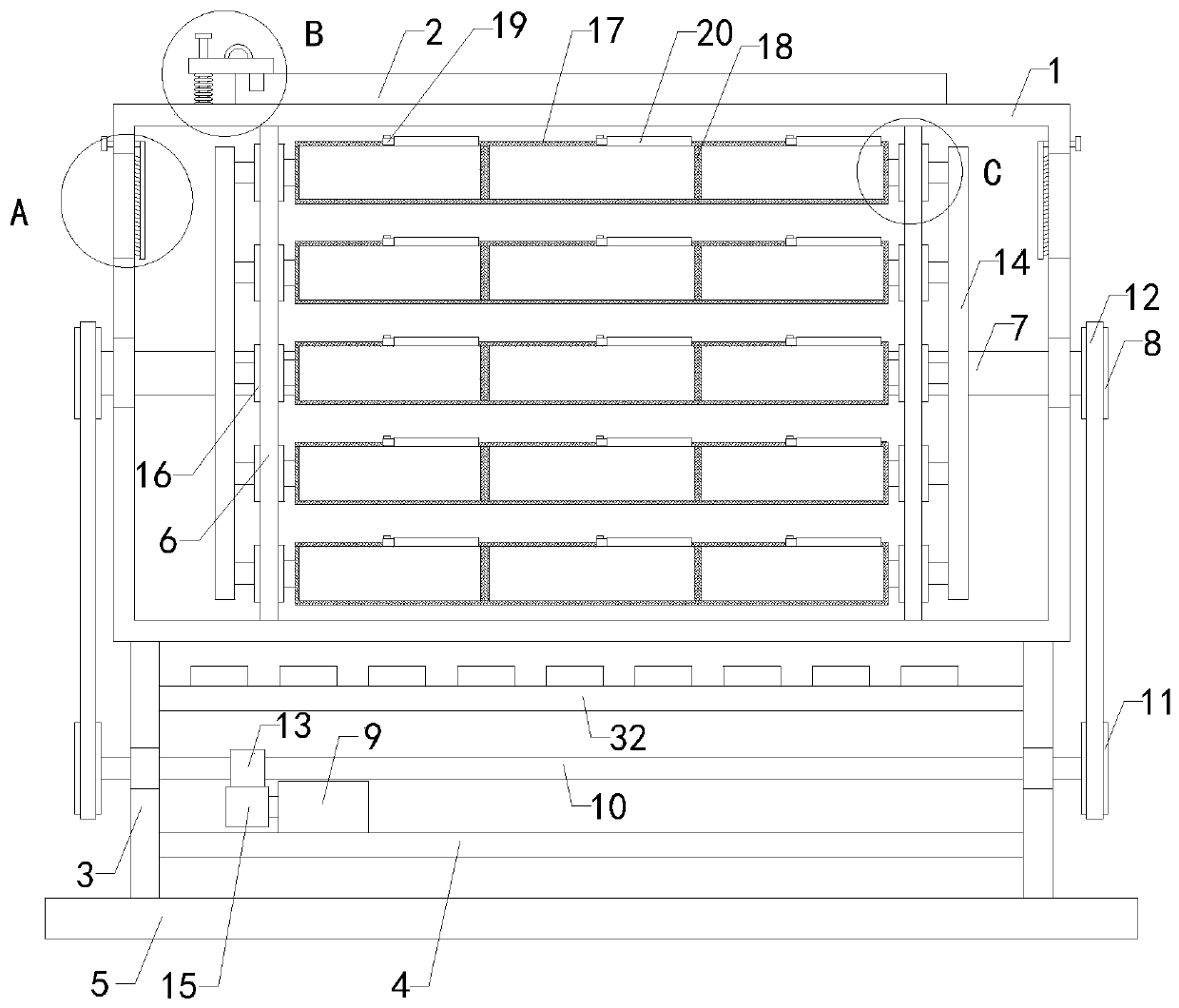

[0028] refer to Figure 1-6 , a stewed food production equipment for uniformly stewed food materials, comprising a tank body 1 and a driving device, the inside of the tank body 1 is provided with a working cavity for placing sauce, and the top of the tank body 1 is horizontally provided with a pick-and-place opening, It is convenient to take and put the stewed products. A sliding cover 2 is arranged on the take-and-release opening for opening and closing the take-and-release opening, and the left and right sides of the bottom end of the tank body 1 are longitudinally provided with support plates 3, two support plates 3 A connecting plate 4 is arranged transversely between them, and a placing plate 5 is arranged transversely at the bottom ends of the two supporting plates 3 to improve the supporting capacity of the tank body 1, and two fixed ring gears are arranged symmetrically on the left and right sides of the working chamber 6, and the peripheral outer walls of the two fixe...

Embodiment 2

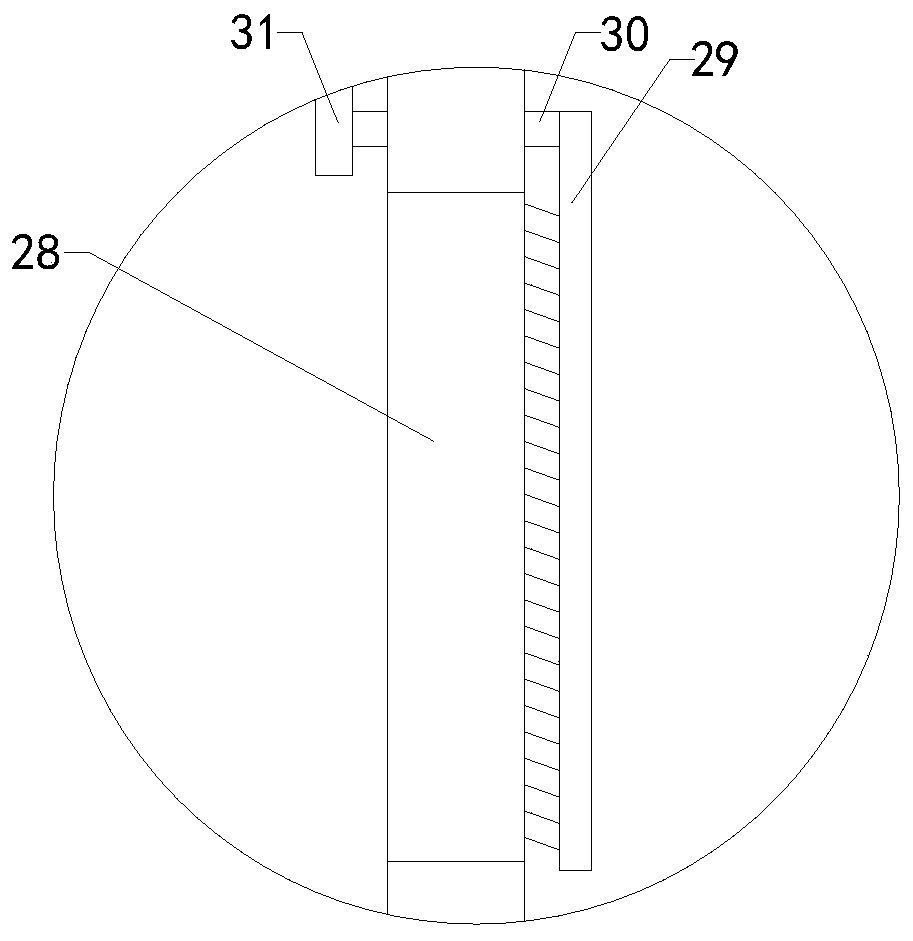

[0032] refer to Figure 1-6 , a stewed food production equipment for uniformly stewed food materials, the upper side of the left side wall and the right side wall of the tank body 1 are provided with observation ports, and each of the observation ports is provided with a transparent baffle 28, each The inner wall of the transparent baffle 28 is provided with a cleaning rod 29, and the top of each cleaning rod 29 is horizontally provided with a rotating shaft 30, and one end of each rotating shaft 30 passes through the side wall of the tank body 1 above the viewing port and extends Out to the outside of the tank body 1, the rotating shaft 30 is rotatably and sealedly connected with the side wall of the tank body 1, and the rotating shaft 30 is provided with a handle 31, and the handle 31 is located outside the tank body 1.

[0033] The difference between this embodiment and embodiment 1 is that on the basis of implementation 1, an observation port is added. The working principl...

Embodiment 3

[0035] refer to Figure 1-6 , a stewed food production equipment for uniformly stewed food, the bottom end of the tank body 1 is provided with a heating hob assembly 32 transversely, and the left and right ends of the heating hob assembly 32 are connected to the inner side walls of two support plates 3 .

[0036] The difference between this embodiment and Embodiment 1 is that, on the basis of Embodiment 1, a heating hob assembly 32 is added. The natural gas connection can be used to heat the halogen products according to the halogenation conditions, reducing the limitation of use.

[0037] The model of the drive motor 9 described in Embodiment 1 is: YX3-132M-4B3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com