Processing technology of canned pears

A processing technology, pear technology, applied in the field of canned pear processing technology, can solve the problems affecting the color and luster of the final pear, affecting the taste of the final can, and oxidation of the surface of the pear, and achieve the effect of good blunt enzyme effect, moderate hardness and complete shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

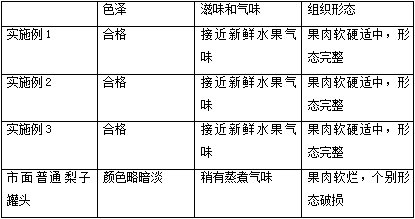

Examples

Embodiment 1

[0021] A processing technology for canned pears, comprising the following production steps:

[0022] (1) Processing of pear raw materials: select pears with appropriate weight, pure color, fresh, moderately ripe, and complete pears, wash them, remove surface attachments, heat treat pears to disinfect, sterilize, remove stems and stones , cut into blocks;

[0023] (2) Cold water treatment: Soak the massive pears obtained in step (1) in deionized water at 5°C for 6 minutes, then take them out for later use;

[0024] (3) Ultrasonic deactivation: put the lump pears treated in step (2) into an ultrasonic container, add sucrose, and perform ultrasonic deactivation treatment;

[0025] (4) Preparation of auxiliary materials: Boil deionized water in a pot, then add food preservatives and vitamin C into the boiling water and stir for 5 minutes, then cool naturally;

[0026] (5) Sealing and sterilization: Mix the pear raw materials obtained in step (3) with the auxiliary materials obta...

Embodiment 2

[0033] A processing technology for canned pears, comprising the following production steps:

[0034] (1) Processing of pear raw materials: select pears with appropriate weight, pure color, fresh, moderately ripe, and complete pears, wash them, remove surface attachments, heat treat pears to disinfect, sterilize, remove stems and stones , cut into blocks;

[0035] (2) Cold water treatment: Soak the massive pears obtained in step (1) in deionized water at 10°C for 10 minutes, then take them out for later use;

[0036] (3) Ultrasonic deactivation: put the lump pears treated in step (2) into an ultrasonic container, add sucrose, and perform ultrasonic deactivation treatment;

[0037] (4) Preparation of auxiliary materials: Boil deionized water in a pot, then add food preservatives and vitamin C into the boiling water and stir for 5 minutes, then cool naturally;

[0038] (5) Sealing and sterilization: Mix the pear raw materials obtained in step (3) with the auxiliary materials ob...

Embodiment 3

[0045] A processing technology for canned pears, comprising the following production steps:

[0046] (1) Processing of pear raw materials: select pears with appropriate weight, pure color, fresh, moderately ripe, and complete pears, wash them, remove surface attachments, heat treat pears to disinfect, sterilize, remove stems and stones , cut into blocks;

[0047] (2) Cold water treatment: Soak the massive pears obtained in step (1) in deionized water at 8°C for 8 minutes, then take them out for later use;

[0048] (3) Ultrasonic deactivation: put the lump pears treated in step (2) into an ultrasonic container, add sucrose, and perform ultrasonic deactivation treatment;

[0049] (4) Preparation of auxiliary materials: Boil deionized water in a pot, then add food preservatives and vitamin C into the boiling water and stir for 5 minutes, then cool naturally;

[0050] (5) Sealing and sterilization: Mix the pear raw materials obtained in step (3) with the auxiliary materials obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com