A robot reconfiguration control method, system and robot

A control method and control system technology, applied in the field of industrial production automation, to achieve the effects of convenient replacement, cost reduction, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

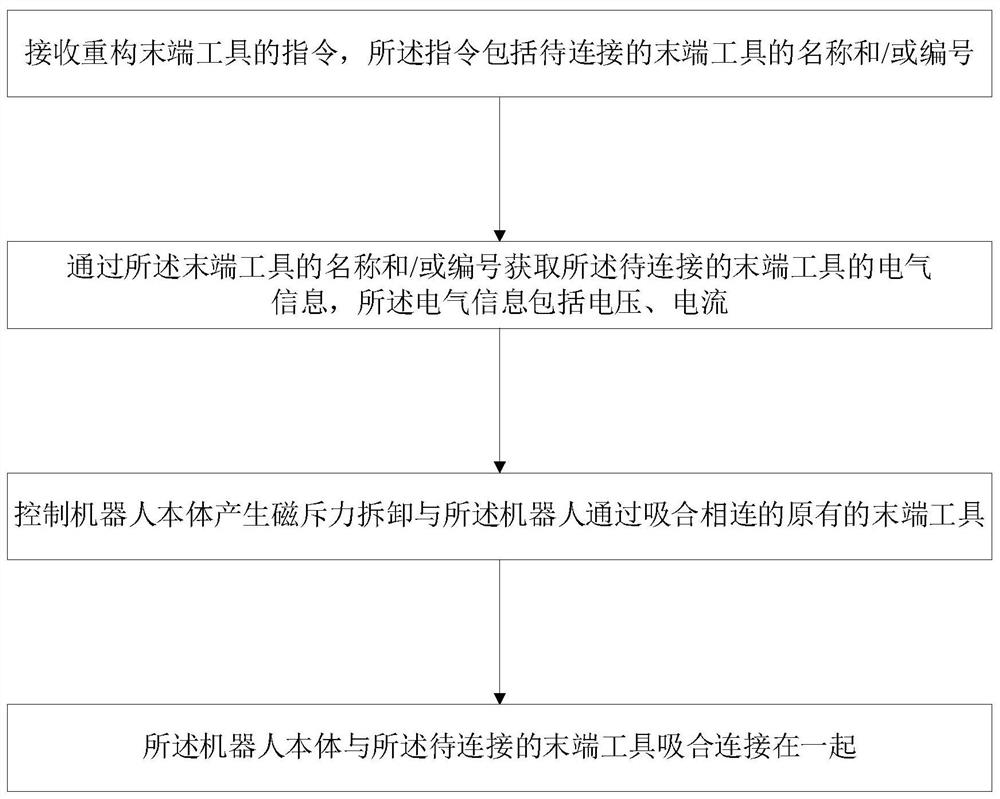

[0038] Such as figure 1 As shown, the present invention provides a robot reconfiguration control method, comprising the following steps:

[0039] S1: Receive an instruction to reconfigure the end tool, where the instruction includes the name and / or number of the end tool to be connected;

[0040] S2: Obtain the electrical information of the terminal tool to be connected through the name and / or number of the terminal tool, the electrical information including voltage and current;

[0041] S3: Control the robot body to generate a magnetic repulsion force to remove the original end tool connected to the robot through suction;

[0042] S4: The robot body and the end tool to be connected are sucked together.

[0043] Through the method of the invention, the robot can quickly and autonomously replace the end tool without external force intervention.

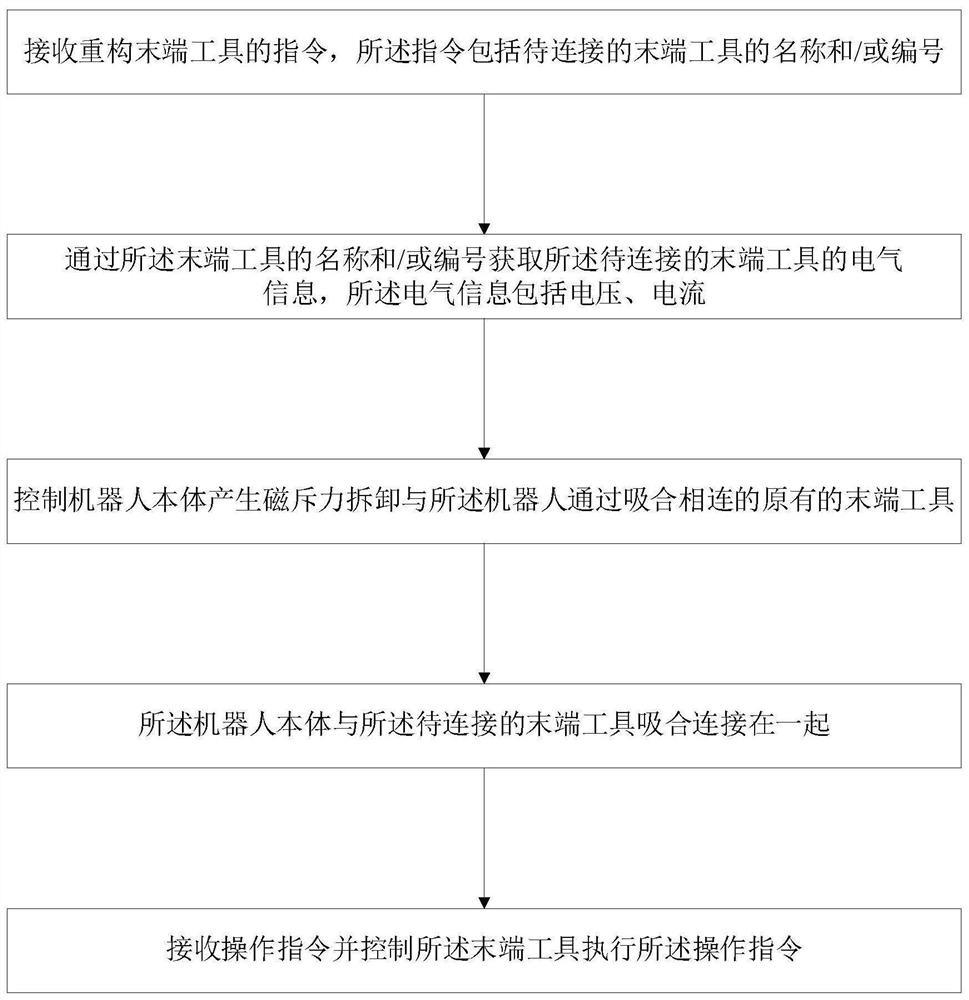

[0044] Such as figure 2 As shown, the robot reconfiguration control method of the present invention also includes the following ...

Embodiment 2

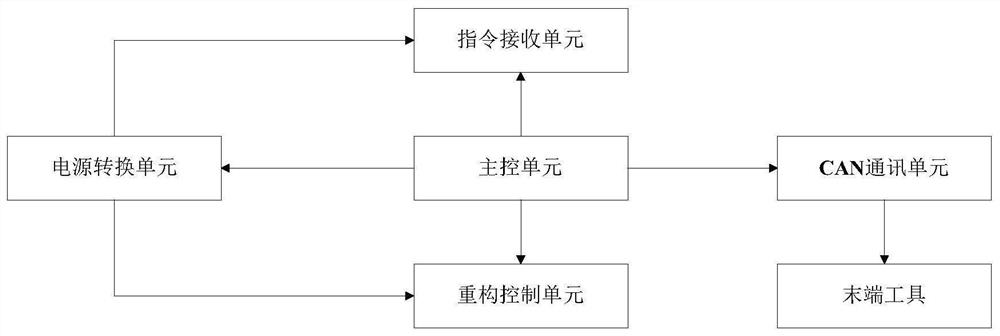

[0051] Such as image 3 As shown, a robot reconstruction control system includes:

[0052]The power conversion unit is used to receive the bus voltage of the robot body, and output the voltage of the magnetic repulsion force required to disassemble the end tool by raising or lowering the bus voltage, and the end tool is suction-connected to the robot body;

[0053] Instruction receiving unit, including bluetooth module, WIFI module and wireless control terminal, used to receive instructions;

[0054] a reconfigurable control unit for providing voltage to said end tool;

[0055] A CAN communication unit, configured to receive instructions from the instruction receiving unit and transmit them to the terminal tool;

[0056] The main control unit is connected with the power conversion unit, the instruction receiving unit, the reconstruction control unit, and the CAN communication unit and controls the power conversion unit, the instruction reception unit, and the reconstruction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com