Quasi-zero-stiffness floating slab ballast bed system based on positive and negative stiffness parallel connection

A quasi-zero stiffness, positive and negative stiffness technology, applied in the field of quasi-zero stiffness floating slab track bed system, can solve problems such as inability to effectively isolate low-frequency vibration components, achieve simple passive vibration isolation devices, reduce vibration isolation starting frequency, The effect of widening the vibration isolation bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to fully understand the beneficial effects of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is only used to explain the present invention and does not limit the protection scope of the present invention.

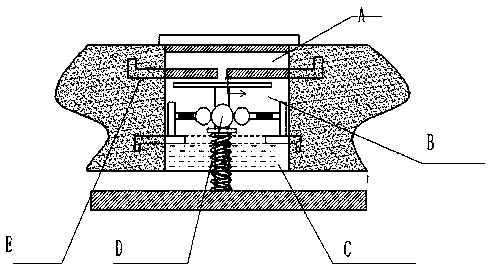

[0053] Such as figure 1 Shown is a schematic structural diagram of a quasi-zero stiffness floating slab ballast bed system based on positive and negative stiffness parallel connections.

[0054] It can be seen from the figure that it is a schematic structural diagram of a quasi-zero-stiffness floating slab track bed system based on positive and negative stiffness parallel connections. A is the installation chamber, and B is the placement chamber for the four-spring roller ball quasi-zero-stiffness vibration isolator , C is the damping chamber, D is the installation diagram of the vibration isolator, and E is the external adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com