Method for quickly evaluating cycle performance of high-nickel anode material for lithium-ion battery

A lithium-ion battery and cathode material technology, which is applied in the field of rapid evaluation of the cycle performance of high-nickel cathode materials in lithium-ion batteries, can solve problems such as high cost, long time consumption, and high energy consumption, and achieve reduced evaluation costs, reduced energy consumption, and The effect of strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

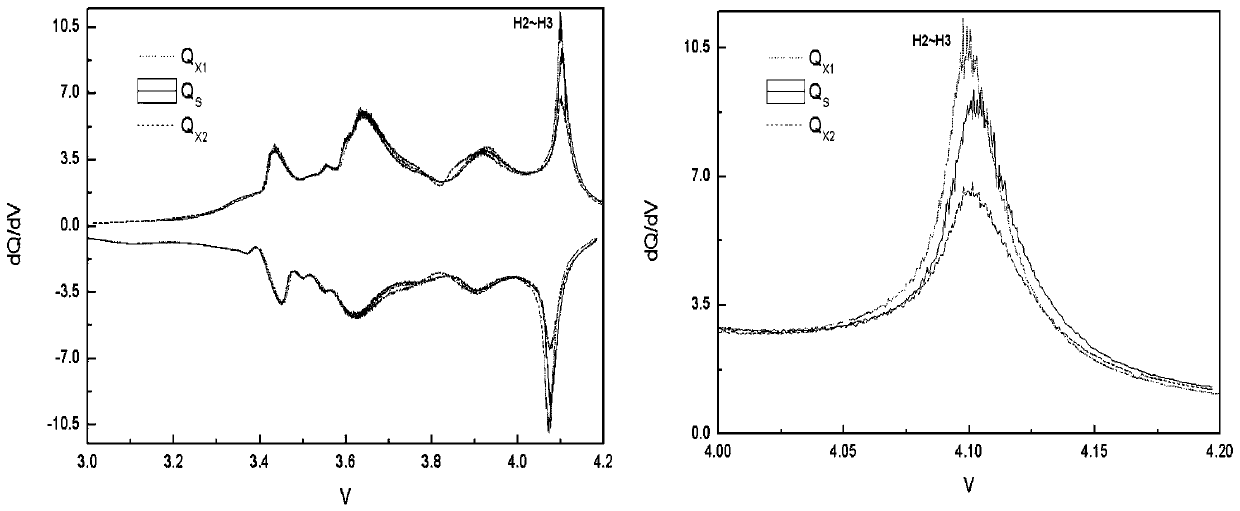

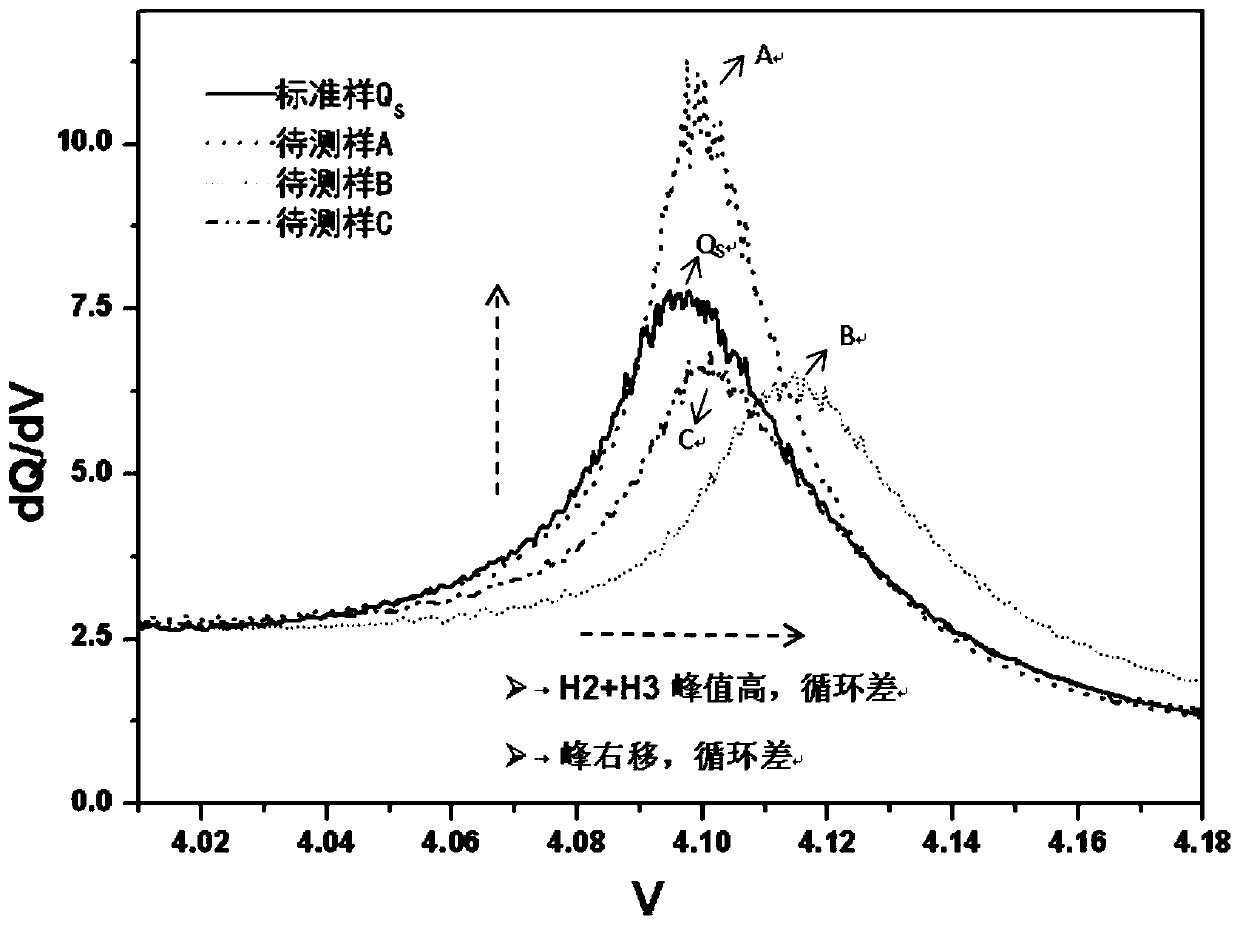

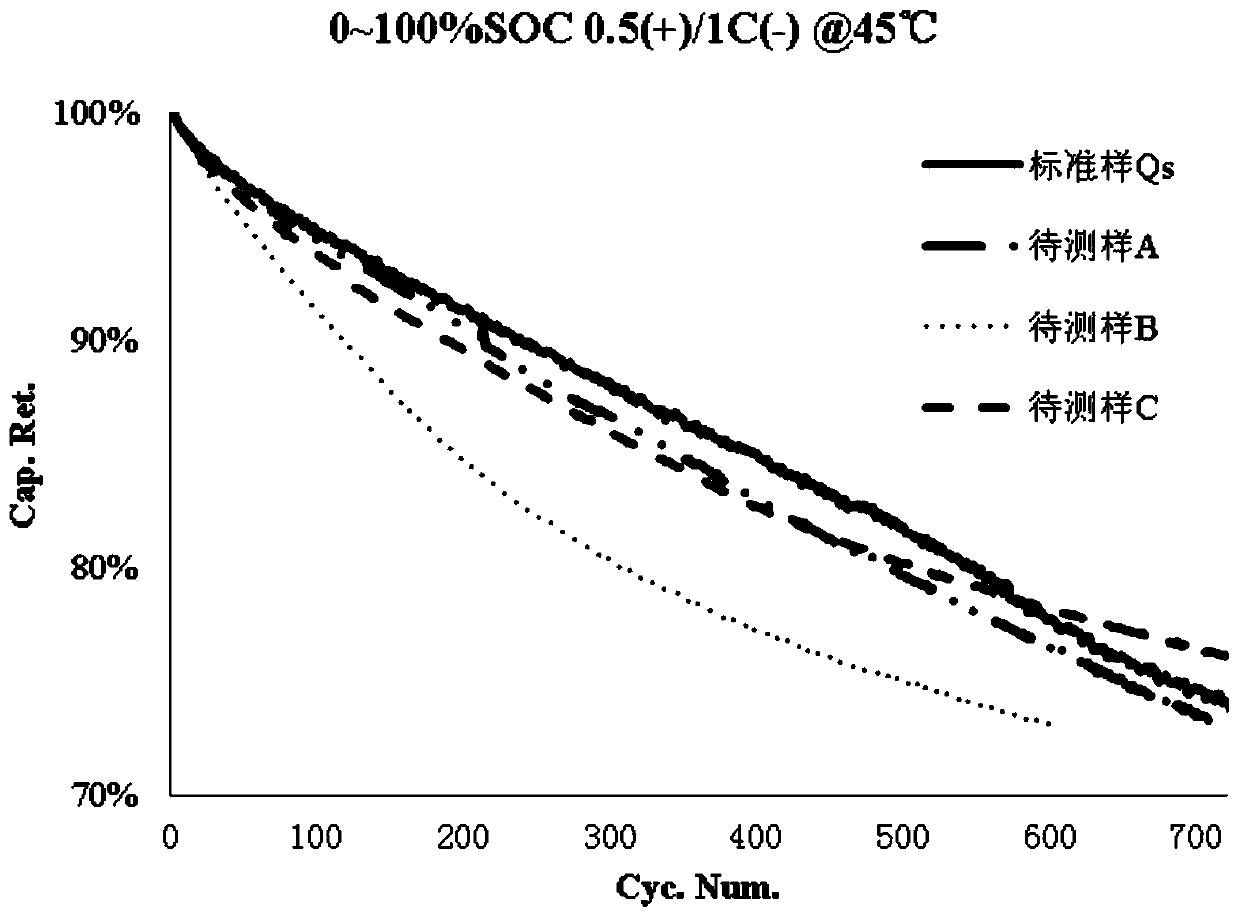

[0079] A method for rapidly evaluating the cycle performance of high-nickel positive electrode materials for lithium-ion batteries, comprising the following steps:

[0080] S11. Provide the high-nickel positive electrode material to be tested and the standard high-nickel positive electrode material that meets the preset cycle performance requirements, and combine the standard high-nickel positive electrode material and the high-nickel positive electrode material to be tested with the same negative electrode and separator according to the same method The method is respectively assembled into a cylindrical 18650 battery to obtain a standard battery and a battery to be tested; wherein, the high-nickel positive electrode material to be tested is the same as the positive electrode material in the standard high-nickel positive electrode material, and in the standard high-nickel positive electrode material, nickel The weight percentage of the element accounts for more than 80% of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com