Centroid-driven focusing mechanism based on flexible hinge

A flexible hinge and center of mass technology, applied in the field of optical instruments, can solve problems such as difficult adjustment, achieve high support rigidity, simple and reliable driving form, and improve the effect of motion straightness and angular deviation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

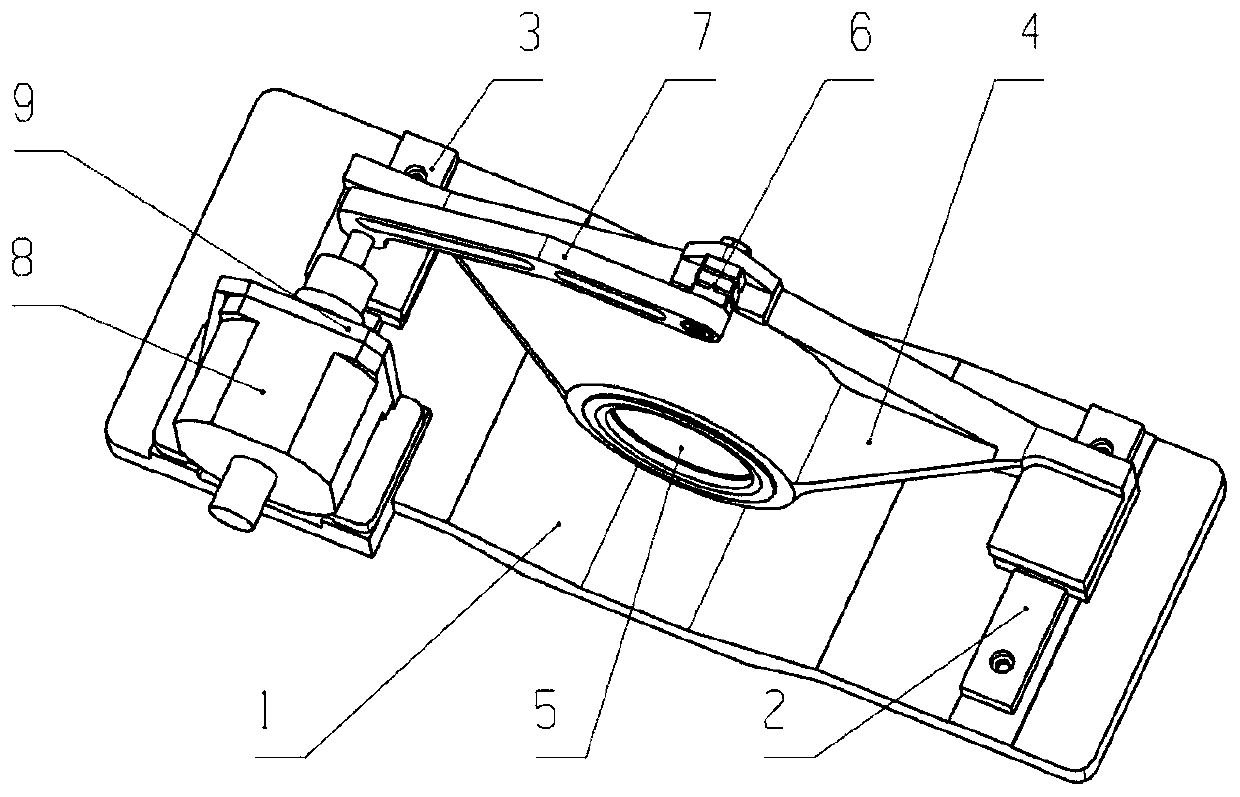

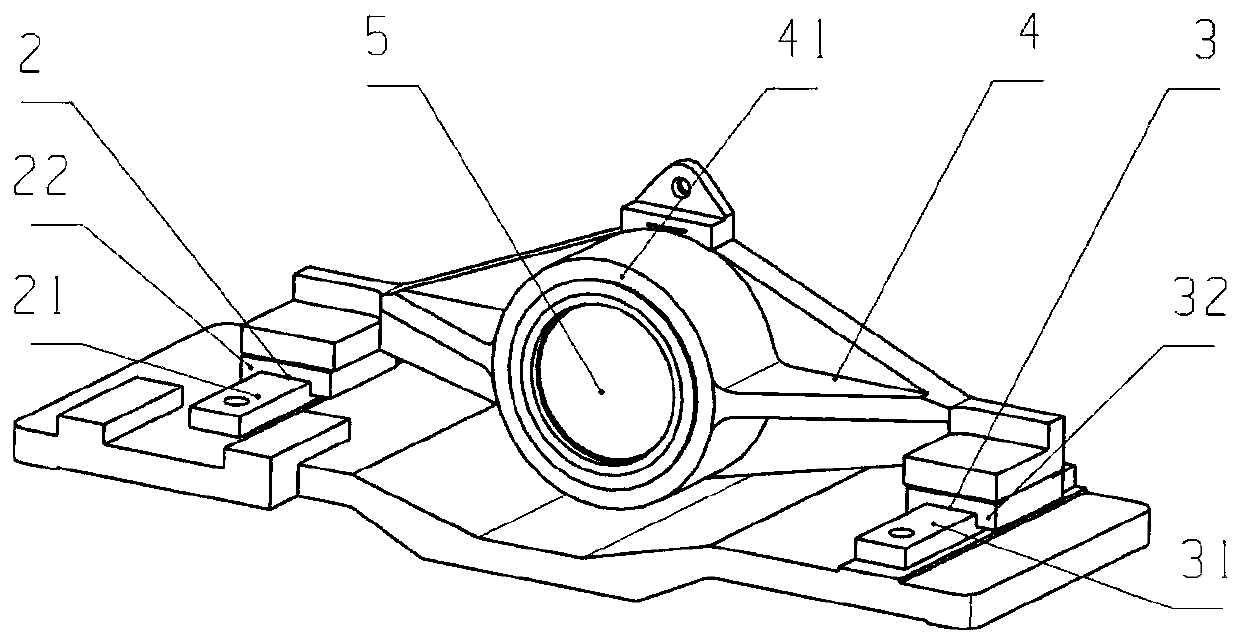

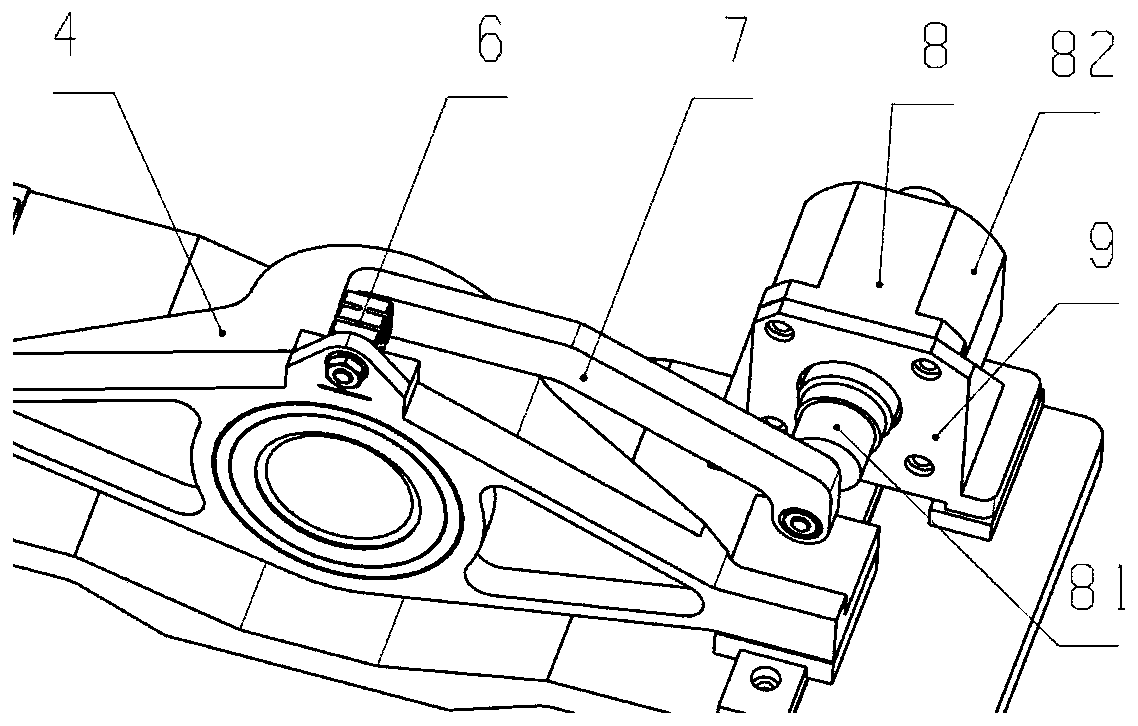

[0022] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0023] A centroid-driven focusing mechanism based on a flexible hinge includes a base, two sets of guide rail sliders, a mirror group bracket, an optical mirror group, a flexible hinge, a drive link, a linear motor, and a linear motor bracket. The base is the main bearing and integrated part of the whole mechanism, and the base can fix the whole mechanism in the external optical system through screws. The two groups of guide rail sliders move in the same direction and maintain a suitable span. The guide rail part is fixed on the base through mounting screws, and the slider part is fixedly connected to both sides of the mirror group bracket through screws. The two sets of guide rail sliders pass through Combined assembly and adjustment to ensure its own linear motion accuracy. The mirror group bracket is the main bearing part of the moving part, which needs to ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com