Method for automatically and accurately measuring abrasion loss of cutter based on gray image probability

A tool wear and grayscale image technology, which is applied in the field of tool wear measurement in NC machining, can solve problems such as large reconstruction errors and missing original boundaries, and achieve the effects of improved accuracy, high measurement efficiency, and fast labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0048] Such as Figure 1-7 shown.

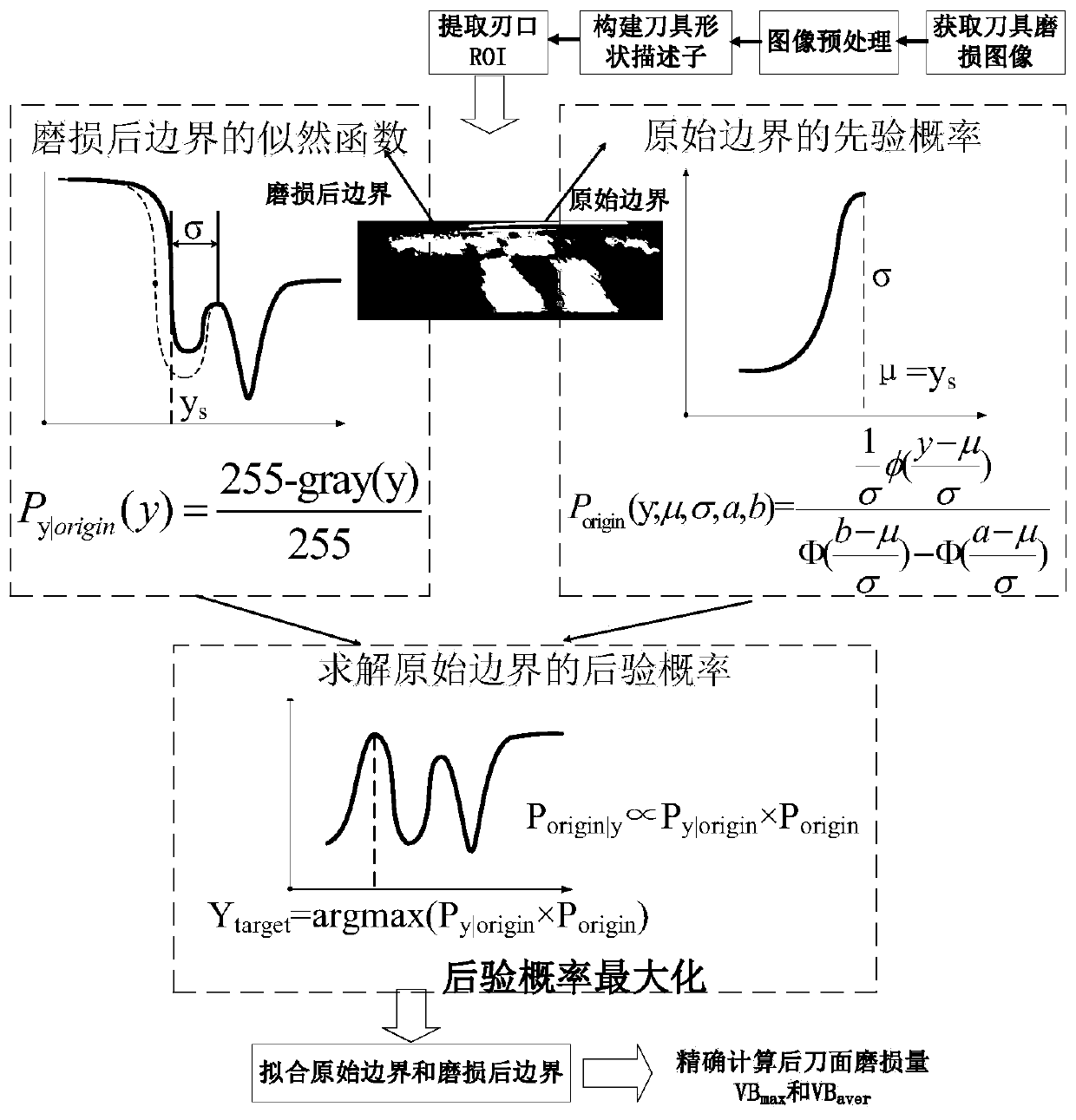

[0049] An automatic and accurate measurement method for tool wear based on grayscale image probability, the process is as follows figure 1 As shown, the specific steps are as follows:

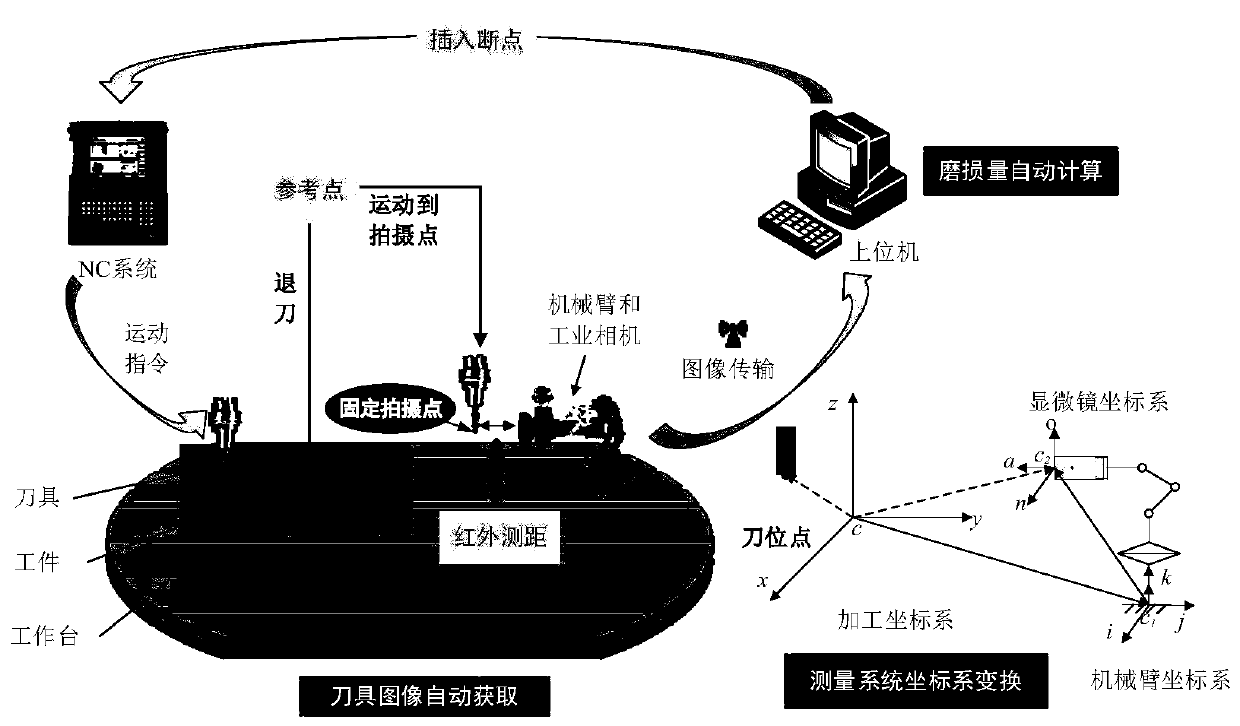

[0050] Step 1. Image acquisition, mainly through a set of on-machine automatic shooting system to acquire tool wear images in the machining gap, such as figure 2 shown;

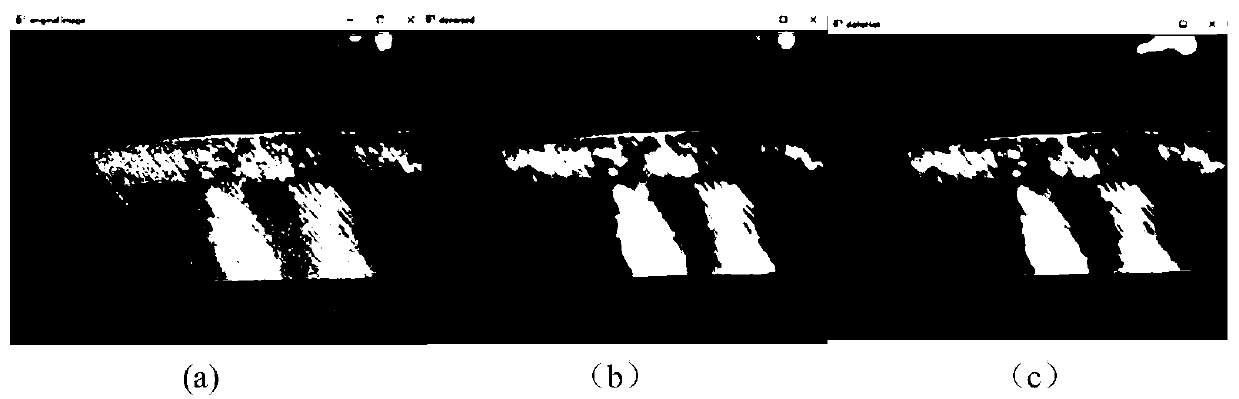

[0051] Step 2, image preprocessing, including image grayscale, image denoising and image enhancement, such as image 3 shown;

[0052] Step 3. TSD-based ROI extraction mainly includes three parts: the construction of detection tool image descriptors, image correction and ROI extraction; among them, the construction of tool image descriptors includes: straight lines in the image, construction of centroid intersection network, and according to the relationship At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com