A preparation method of black silicon substrate with ultra-low reflectivity micro-nano composite structure

A micro-nano composite structure, reflectivity technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of low solar cell efficiency and high surface reflectivity, achieve low surface reflectivity, High repeatability and improved external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

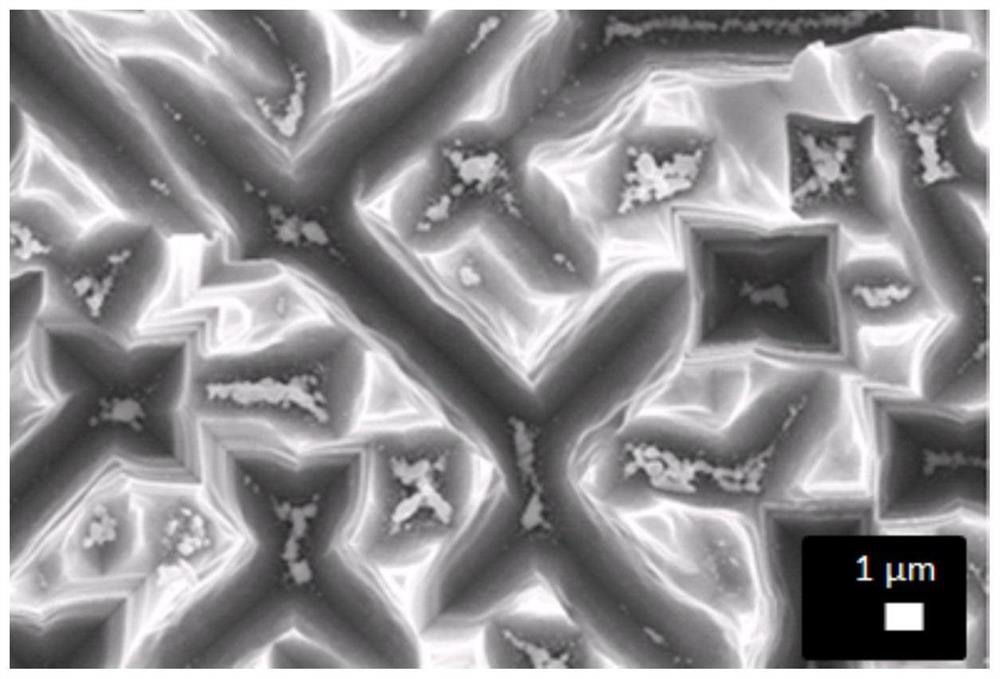

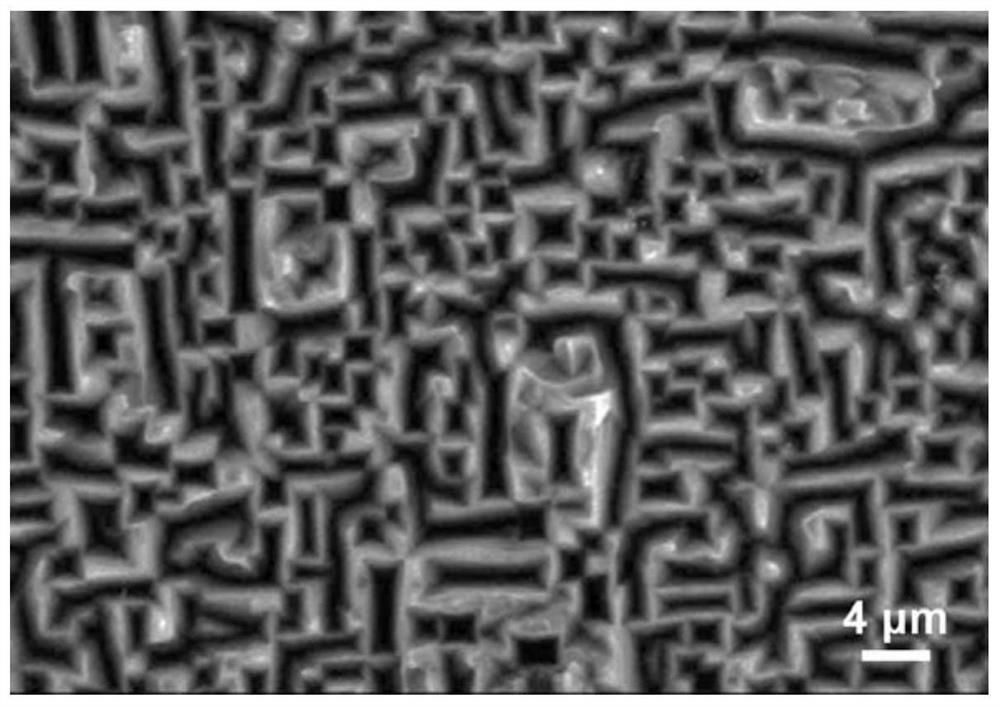

[0026] Specific Embodiment 1: In this embodiment, a method for preparing a black silicon substrate with an ultra-low reflectivity micro-nano composite structure is carried out according to the following steps:

[0027] 1. Use CuNO at a temperature of 40-100°C 3 , HF and H 2 o 2 The silicon substrate is etched with the mixed solution, and the etching time is controlled to be 1-60 minutes to obtain a silicon substrate with a micron-scale light-trapping structure on the surface;

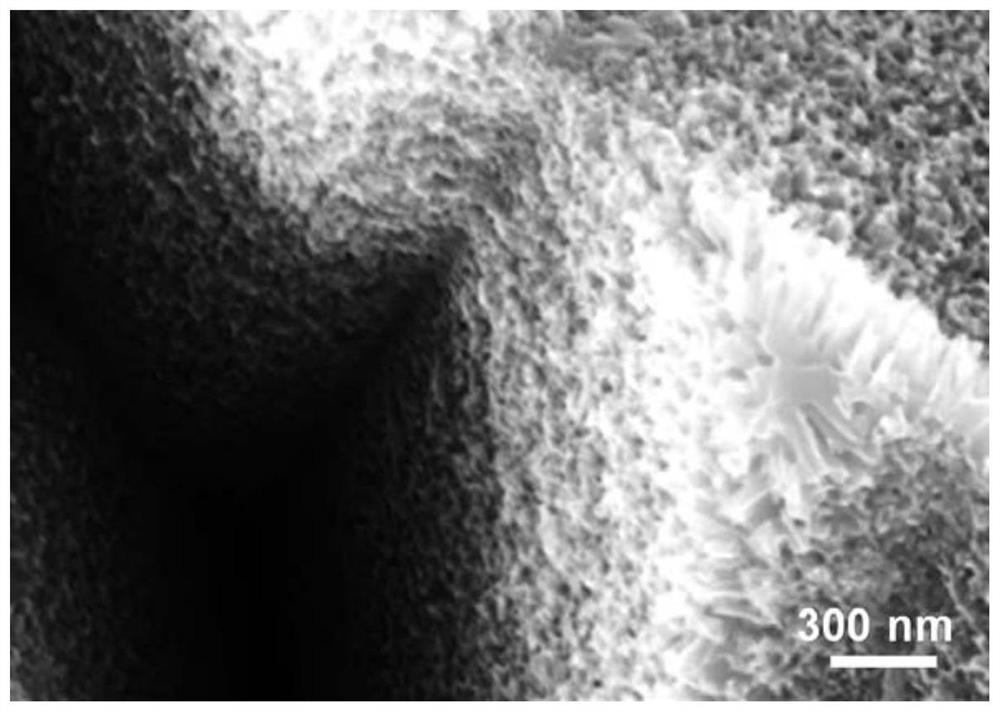

[0028] 2. Put the silicon substrate obtained in step 1 into AgNO at a temperature of 20-100°C. 3 and HF mixed solution for the deposition of silver nanoparticles;

[0029] 3. Put the silicon substrate deposited in step 2 into HF and H at a temperature of 20-100°C. 2 o 2 In the mixed solution, etch for 10-60 minutes to obtain a silicon substrate with a micro-nano composite structure on the surface;

[0030] 4. Put the silicon substrate obtained in step 3 into HNO at a temperature of 20-100°C 3 Kee...

specific Embodiment approach 2

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the CuNO described in step one 3 , HF and H 2 o 2 CuNO in mixed solution 3 The concentration of HF is 0.01~5.00mol / L, the concentration of HF is 1~10mol / L, the concentration of H 2 o 2 The concentration is 0.1~10mol / L. Others are the same as in the first embodiment.

[0035] In this embodiment, by controlling the concentration of the HF solution in step 1, the size, depth, occupation ratio and surface reflectance of the black silicon substrate of the obtained micron-scale light-trapping structure can be effectively regulated.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, the silicon substrate is (100) plane single crystal silicon. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com