MMC (Modular Multilevel Converter)-based bidirectional direct-current converter and control system thereof

A bidirectional DC conversion and control system technology, applied in control/regulation systems, DC power input to DC power output, output power conversion devices, etc., can solve the problem of low output power level, low overall efficiency, bidirectional DC converters Problems such as large switching loss, to achieve the effect of low switching loss, high operating efficiency and low harmonic level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

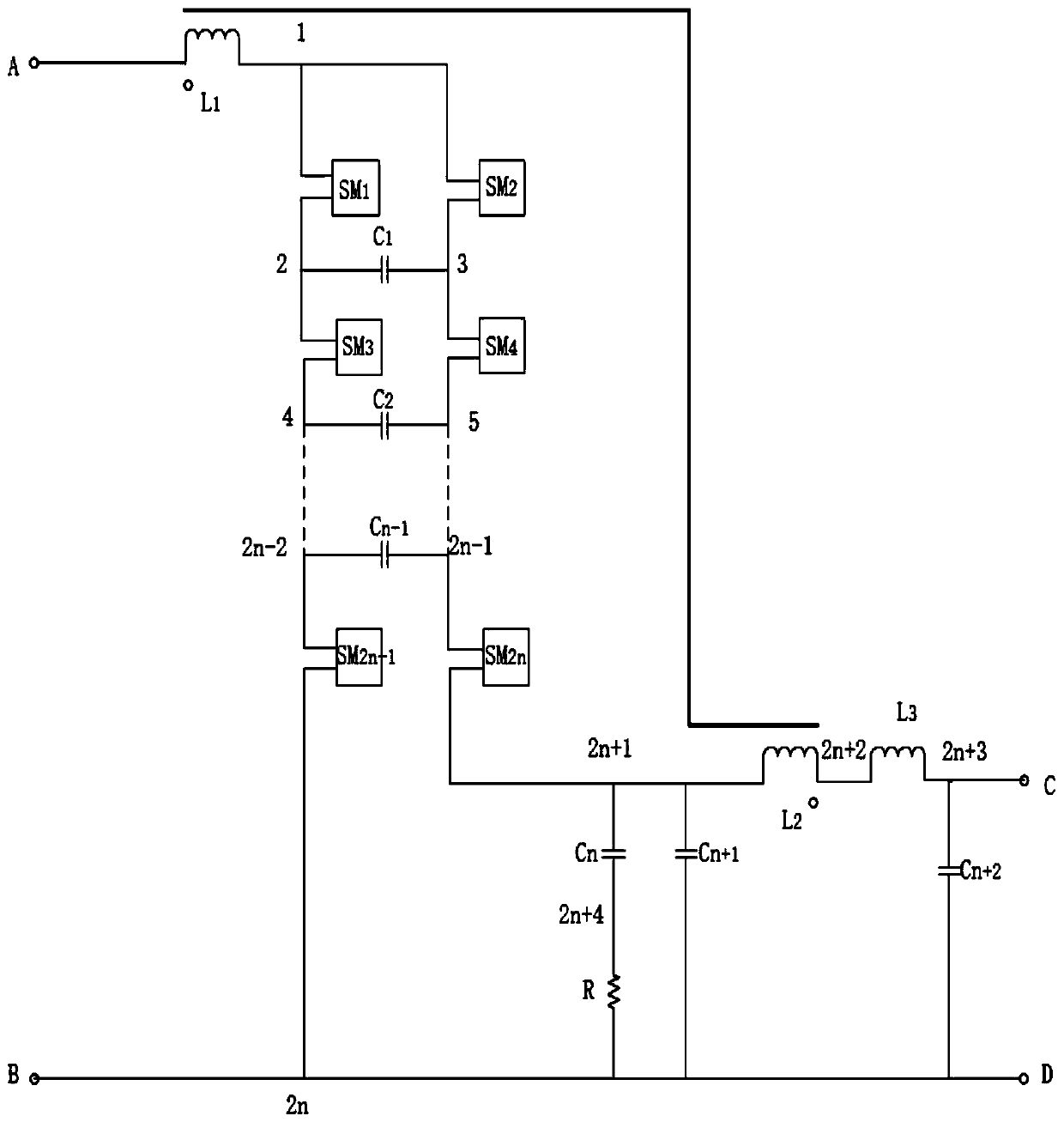

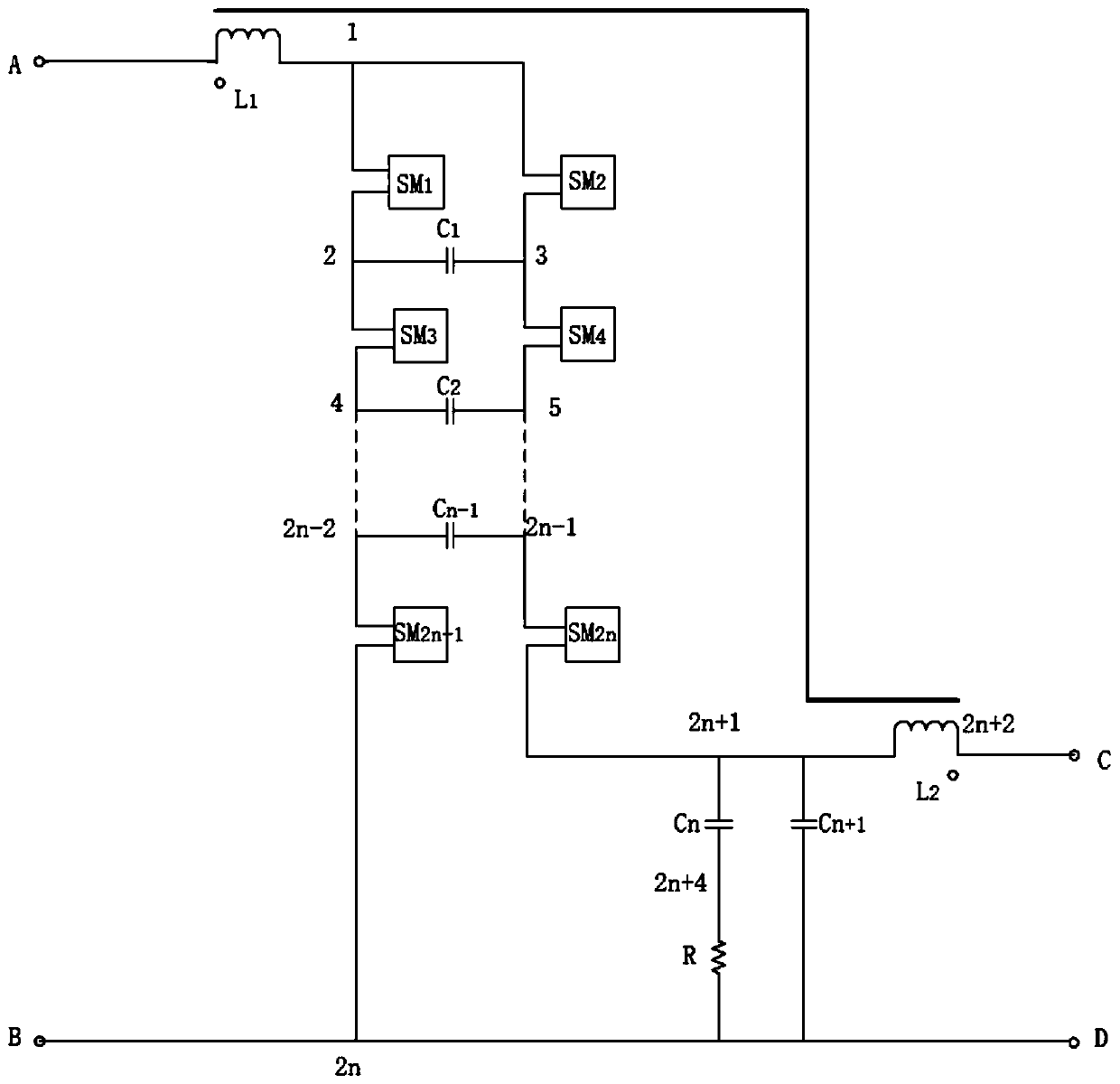

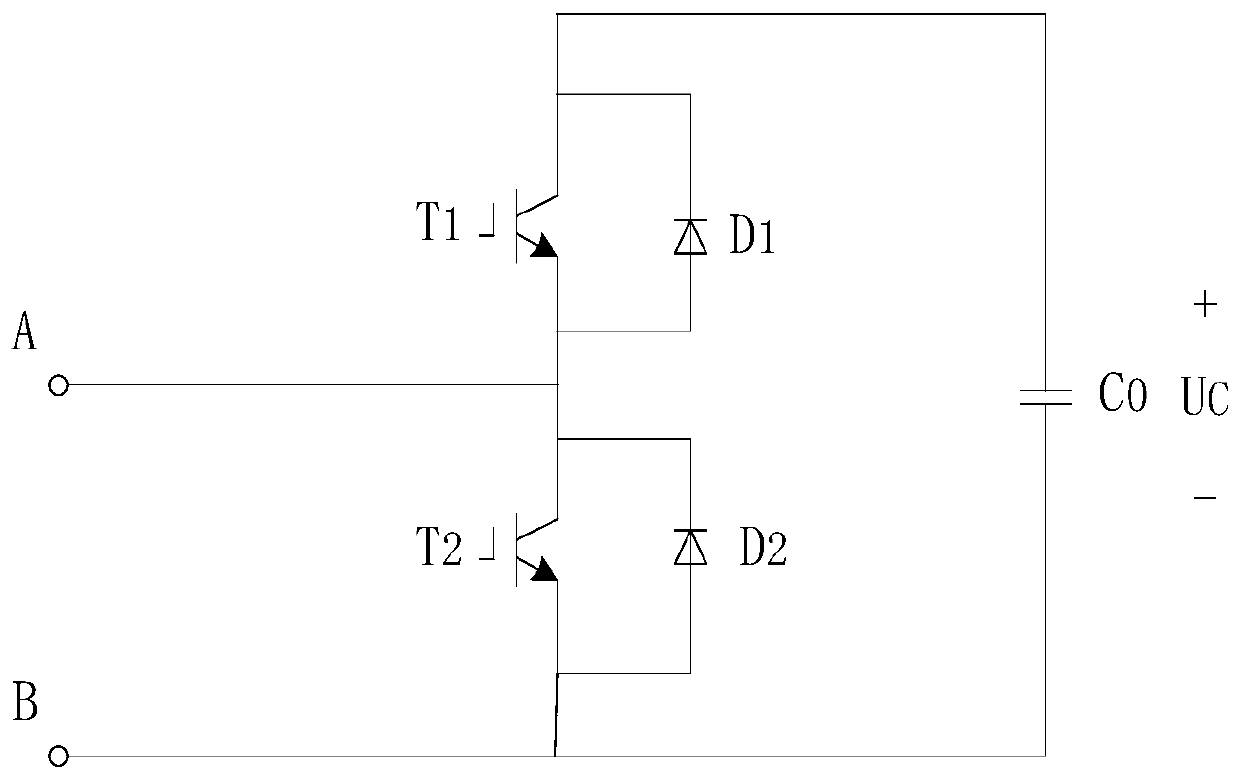

[0023] first see attached figure 1 , which shows a schematic structural diagram of the bidirectional DC converter according to the first embodiment of the present invention. Such as figure 1 As shown, the novel bidirectional DC converter according to the first embodiment of the present invention is a multi-level topology, and the multi-level topology includes a first DC port, a second DC port, and multiple capacitors (specifically, the first Capacitor C1, second capacitor C2, third capacitor C3... nth capacitor Cn, n+1th capacitor Cn+1, n+2th capacitor Cn+2), three energy storage inductors (specifically, energy storage inductor L1 , L2, L3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com