Coil sealant encapsulating device

A sealant and potting technology, which is applied to the device and coating of the surface coating liquid, can solve the following problems such as the size cannot be too large, assembly difficulty, aging, etc., to reduce bubbles, delamination and cracks, and improve Impregnation penetration effect, effect of crack resistance and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

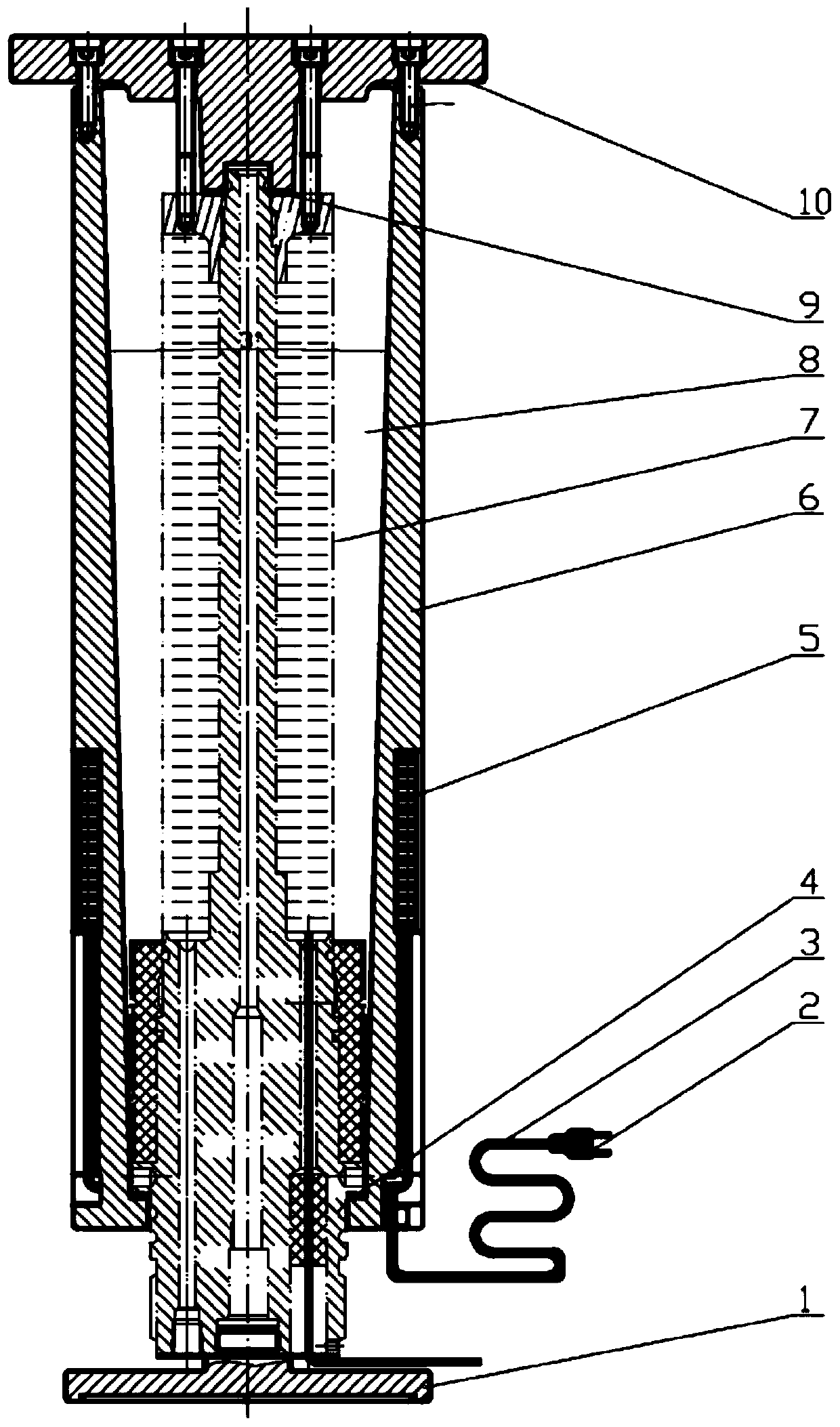

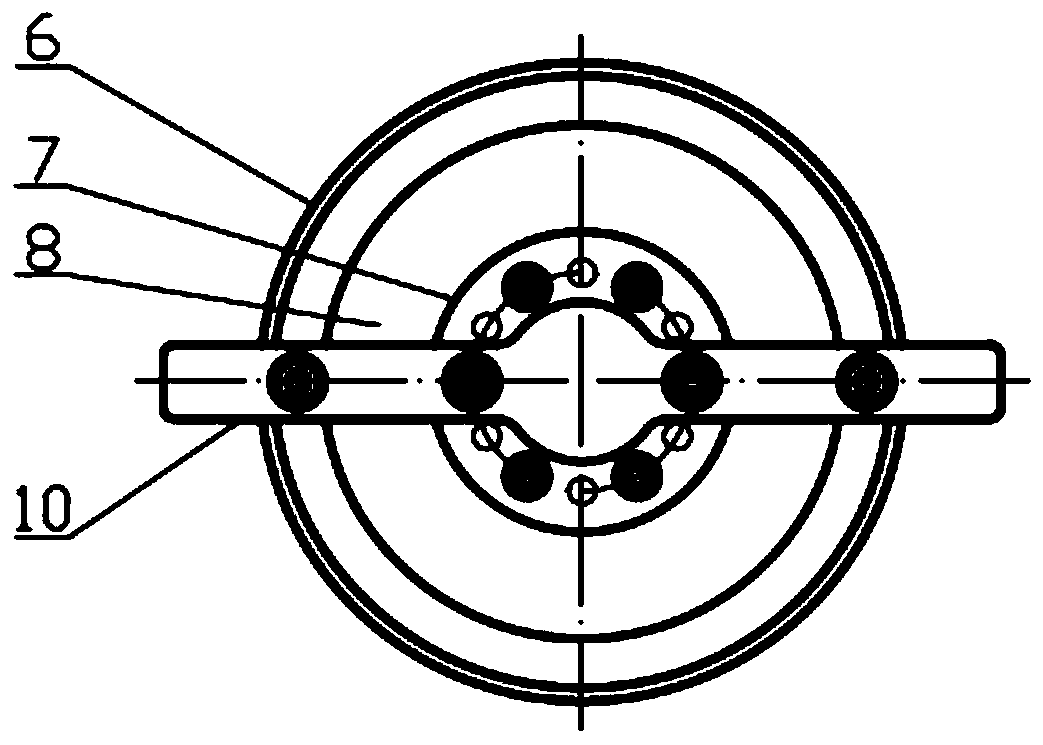

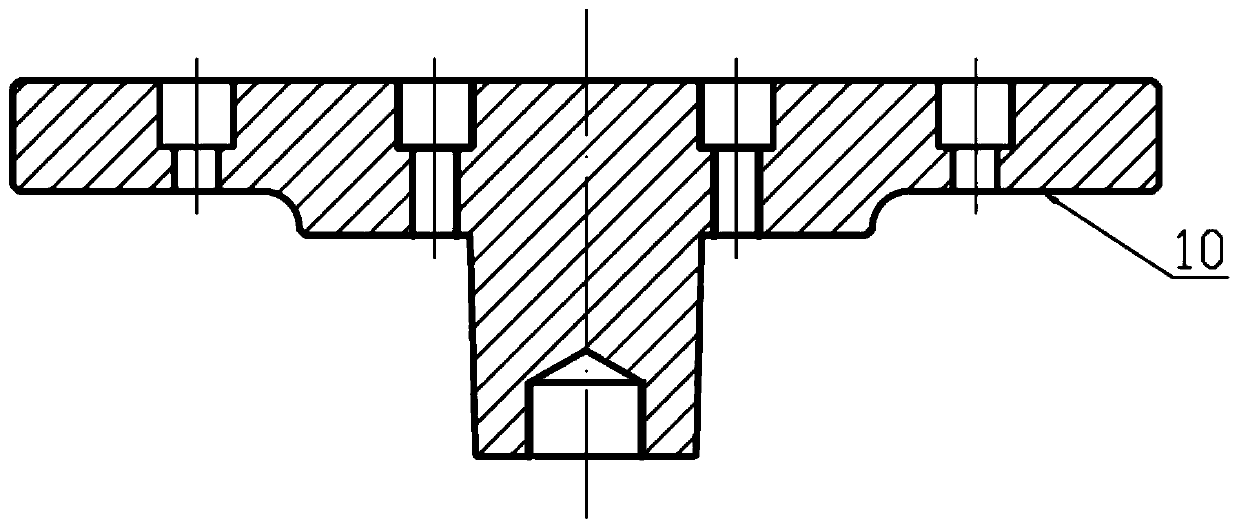

[0015] refer to Figure 1-Figure 3. In the preferred embodiment described below, a coil sealant potting device includes: the potting chamber 6 sealed by the end cap pressing plate 10 and the built-in sealing ring 9 sealed in the groove of the cylindrical boss in the center of the end cap pressing plate 10 and The load coil assembly between the base shaft shoulder rubber sealing ring 4, the inner wall of the potting chamber 6 is shaped with a conical cavity with a draft angle, the small end straight hole in the lower part of the conical cavity uses the lower end to penetrate the load coil assembly 7 and is connected with a screw thread The stepped cylindrical body of the base 1 at the lower end of the load coil assembly 7 and the sealing sleeve on its outer circle fix the load coil assembly 7 between the bottom base shoulder rubber seal ring 4 and the upper seal ring 9, and seal the chamber cylinder 6 The body is provided with a PTC heating sheet 5 surrounding the circumferent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com