Microcapsule essence laundry detergent and preparation method thereof

A technology of microcapsule essence and laundry detergent, which is applied in the direction of chemical instruments and methods, liquid soap, detergent compounding agents, etc., can solve the problems affecting the use effect of products, reducing the tendency of interfaces, thermodynamic instability, etc., and achieves large space stability effect, the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides the preparation method of above-mentioned microcapsule essence laundry liquid, comprises the steps:

[0036] 1) According to the percentage by weight, first mix the cationic polyacrylamide and the acrylate nonionic surfactant uniformly to obtain the mixture A.

[0037] 2) Add other nonionic surfactants to A one by one, and stir evenly to obtain mixture B, set aside;

[0038] 3) Prepare the anionic surfactant first; mix the prepared anionic surfactant with the solvent evenly, and stir to obtain the mixture C;

[0039] 4) Mix mixture B and mixture C evenly, add microcapsule essence, preservative, chelating agent and other ingredients, and stir evenly.

[0040] In the step 3), the anionic surfactant is generally completed in the configuration of the laundry detergent, and it is ready-to-use and ready-to-use. It is usually prepared by neutralizing the corresponding acid with an alkaline neutralizer. Alkaline neutralizing agents such as...

Embodiment 1-8

[0042] The dosage of each component in the laundry detergent of the present invention will be described in detail below through several specific examples and comparative examples. The present invention sets embodiment and comparative example, and each embodiment and corresponding comparative example use the same basic components, that is, surfactants, preservatives, microcapsule flavors and other ingredients and dosages are the same, and the difference is that no cationic polymer is added in the comparative example. Acrylamide.

[0043] Table 1 lists the components of Examples 1-4 and corresponding Comparative Examples 1-4.

[0044]

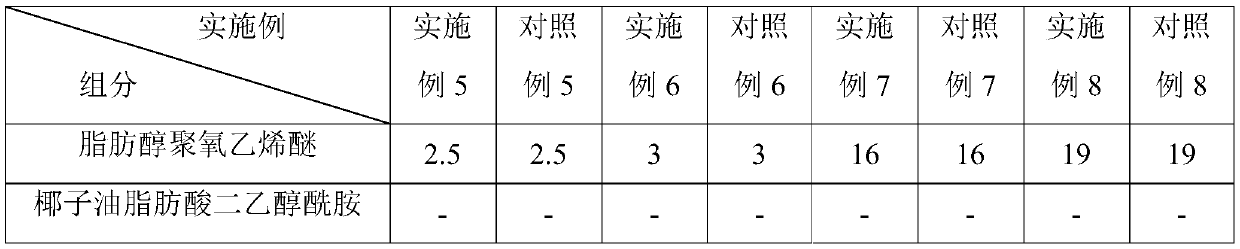

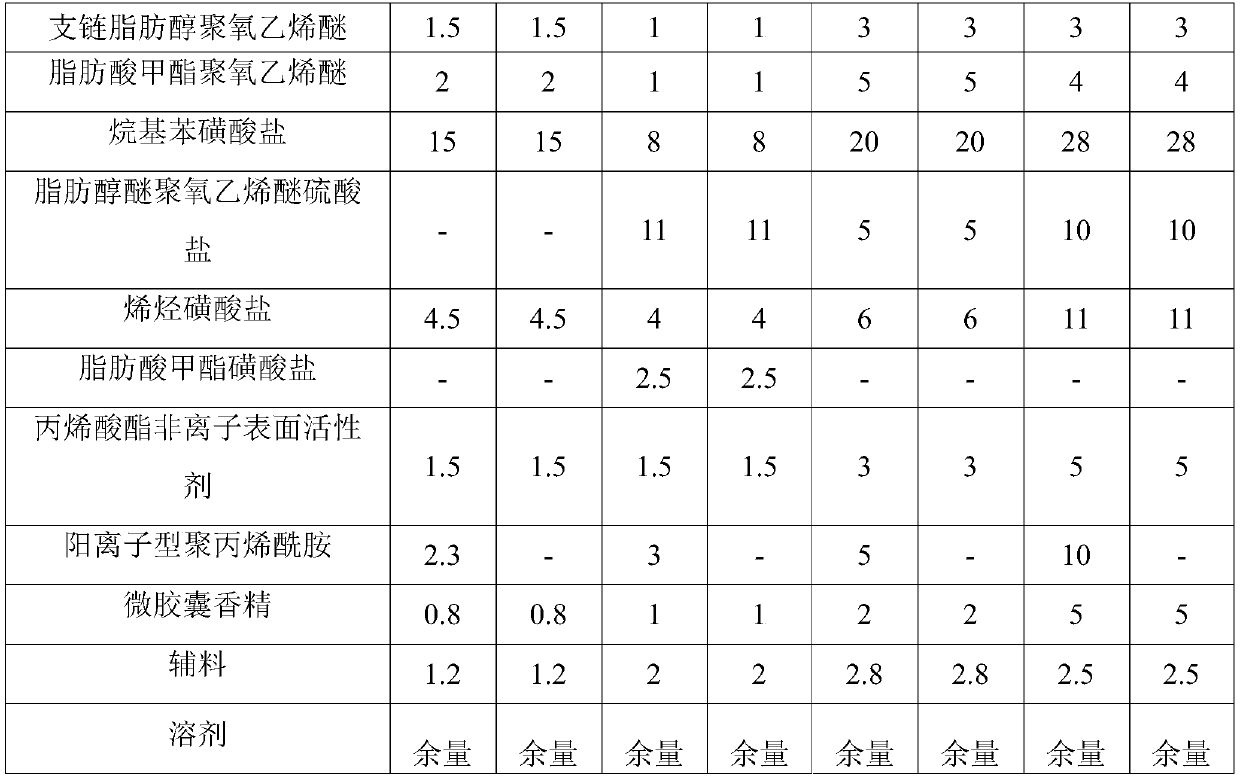

[0045] Table 2 lists the components of Examples 5-8 and corresponding Comparative Examples 5-8.

[0046]

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com