Micro-nano indentation test method suitable for complex curved surface

A test method and technology of indentation test, applied in the direction of applying stable tension/compression to test material strength, test material hardness, measuring device, etc., can solve problems such as poor flexibility, cumbersome and complicated test piece preparation, and low test efficiency. Achieve easy control, save test time, and maintain good results

Active Publication Date: 2020-01-31

JILIN UNIV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a micro-nano indentation test method suitable for complex curved surfaces, which solves the prefabricated work hardening defect on the surface of the test piece in the flattening process of the micro-nano indentation test piece existing in the prior art , The preparation of test pieces is cumbersome and complicated, the test efficiency is low, and the flexibility is poor, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0046] The method will be further described below in conjunction with specific examples:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

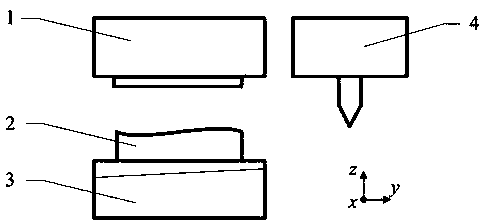

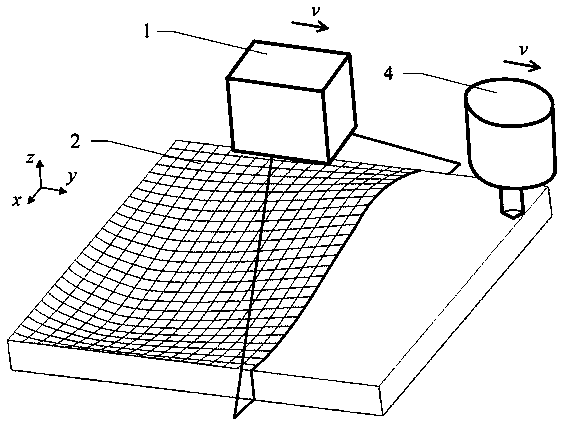

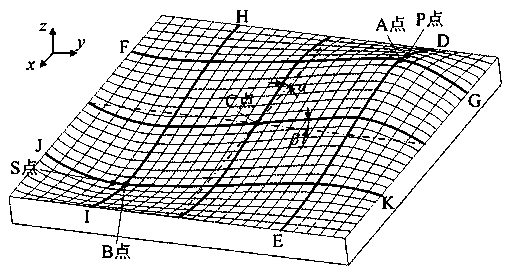

The invention relates to a micro-nano indentation test method suitable for a complex curved surface, and belongs to the technical field of material micro-mechanical property test. According to the method, the surface topography of a material with the complex curved surface is scanned based on a three-dimensional contourgraph, surface topography information of the material is obtained, the inclination angle of a plane where a test piece is located is adjusted to rapidly find an area suitable for indentation test, indentation test is then carried out the area, and the material does not need cutting, grinding and polishing of an original process. The problems that there is a prefabricated processing hardening defect of the surface of the test piece and test piece preparation is tedious and complex in existing leveling of the micro-nano indentation test piece are solved. Compared with the prior art, the method of the invention has the advantages of saving test time, being high in materialsurface performance retentivity and the like, being simple in operation and easy to control, and having a wide application prospect in multiple fields.

Description

technical field [0001] The invention relates to the technical field of material micromechanical performance testing, in particular to a micro-nano indentation test method suitable for complex curved surface surfaces, which is used for testing micro-nano indentation responses of sample materials with complex curved surface structures . Background technique [0002] The micro-nano indentation test technology measures the hardness, elastic modulus and creep properties of the material by parallel measurement of the indentation load value and indentation deformation of the hard indenter with a specific tip geometry indented into the surface of the test piece It is the mainstream method for testing the mechanical properties of material surfaces. However, most of the current micro-nano indentation testing techniques are only tested on specimens with a flat surface. In order to obtain a flat test surface, the material needs to be processed by cutting, grinding, and polishing. This ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/42G01N3/08

CPCG01N3/08G01N3/42G01N2203/0019G01N2203/0071G01N2203/0075G01N2203/0078G01N2203/06G01N2203/0682

Inventor 王顺博赵宏伟李思锐王赵鑫王赫

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com