Compensation device for empty load and temperature rising test system of +/-800kV power transmission and transformation main equipment

A compensation device and temperature rise test technology, applied in circuit devices, reactive power compensation, measurement devices, etc., can solve the problems of single compensation combination, large power supply capacity requirements, and poor system reliability, achieving a wide range of applications and saving construction The effect of large cost and total capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

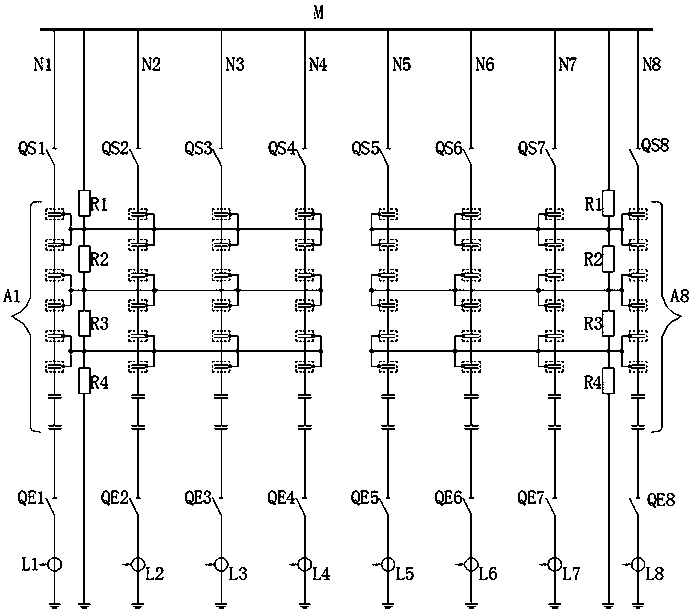

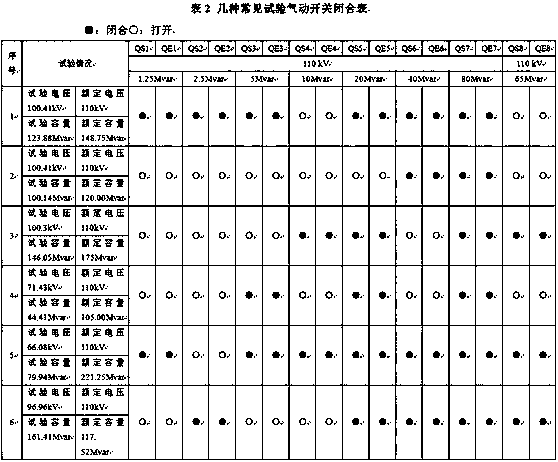

[0021] Embodiment 1, the present invention provides a compensation device for the no-load and temperature rise test system of ±800kV power transmission and transformation main equipment. The bus M is connected to 8 branches N1-N8 in parallel, and the branches include a capacitor bank A1 composed of capacitors connected in series. -A8, and the pneumatic isolating switches QS1-QS8 set between the capacitor bank and the busbar and the pneumatic isolating switches QE1-QE8 set between the capacitor bank and the ground, the lower end of the branch circuit is connected to the current transformer for the test, the branch circuit The bottom end is grounded.

[0022] The whole set of compensation device is divided into two capacitor towers, each tower has 4 branches, and each capacitor tower is equipped with a set of clamping resistors composed of 4 resistors, the bottom end of the clamping resistors is grounded, and the clamping resistors are connected in series Connect the capacitor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com