Production method of gel compounded seafood jelly capable of being sucked

A production method, seafood jelly technology, applied in the direction of food ingredients as odor improvers, food ingredients as taste improvers, food science, etc., can solve problems such as obstacles to popularization, and achieve quality problems, obvious effects, and rich flavor characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

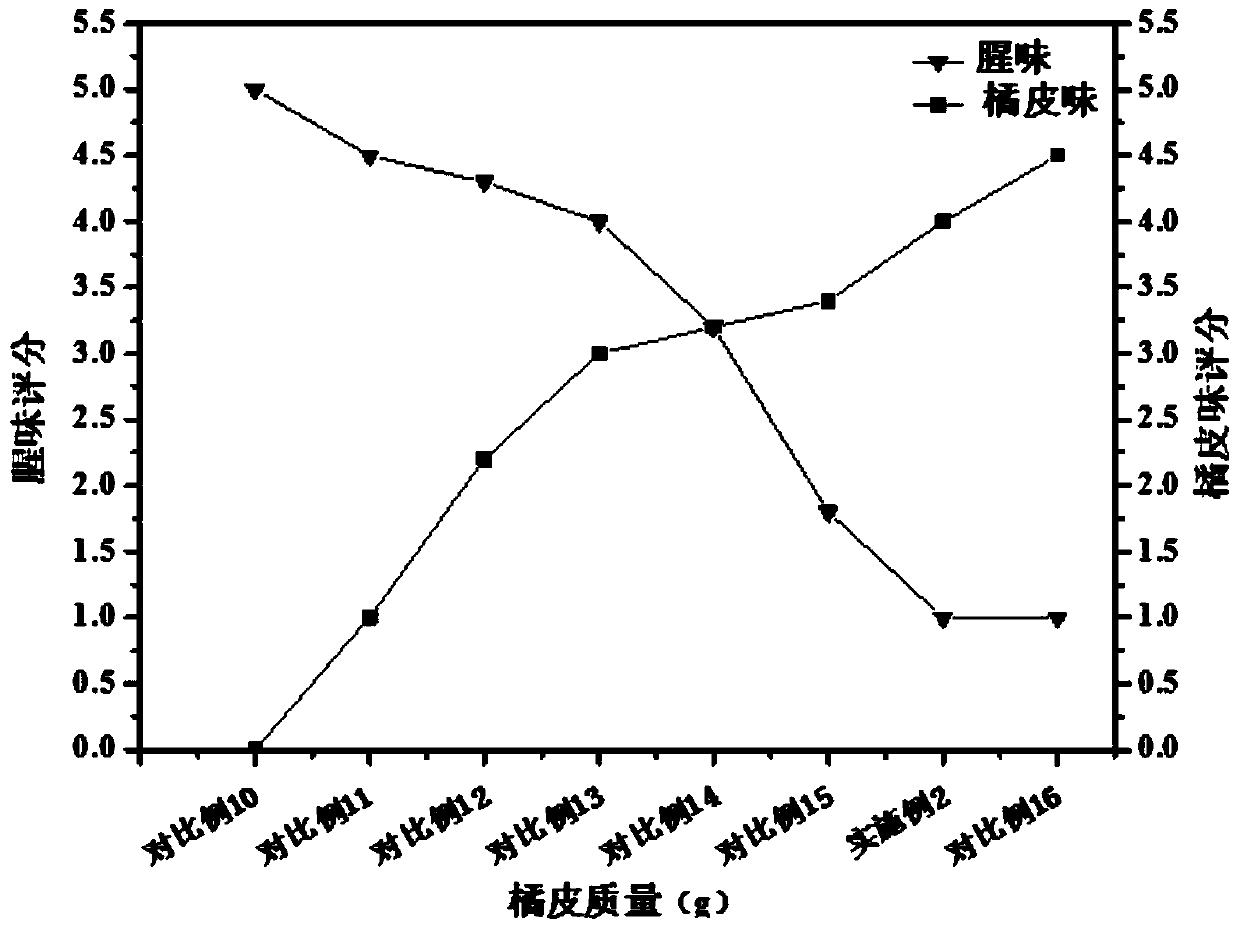

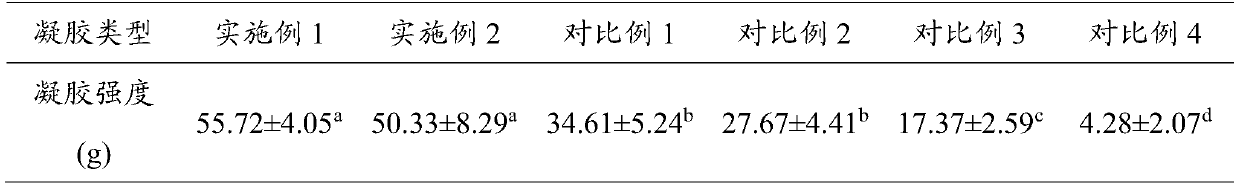

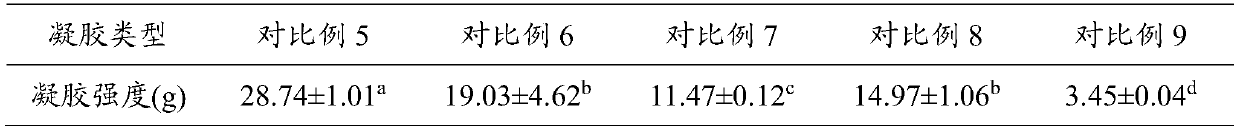

Examples

Embodiment 1

[0058] A method for making inhalable gel compound seafood jelly, comprising the steps of:

[0059] S1. Raw material pretreatment:

[0060] Shrimp preservation and deodorization: Take 9g of Penaeus vannamei, wash with ice water, drain the water, soak in 30g, 4°C crispiness and deodorization solution for 2 hours to get deodorization shrimp; the crispness and deodorization solution It is composed of 0.005g / ml sodium bicarbonate solution and natural deodorizing liquid in a weight ratio of 3.5:1;

[0061] Solid deodorization of scallop pillars: take 10g of scallop pillars of Chlamys farreri, wash them with ice water, drain the water, add them to 40g of soaking solution A, soak at 8°C for 3 hours, and obtain deodorized scallop pillars; the soaking solution A includes the following Components in percentage by weight: 30% of natural deodorizing liquid, 0.2% of edible gelatin, and the balance is water;

[0062] Rehydration and deodorization of algae: Take 2.5g of dried kelp and add 1...

Embodiment 2

[0075] A method for making inhalable gel compound seafood jelly, comprising the steps of:

[0076] S1. Raw material pretreatment:

[0077] Shrimp preservation and deodorization: take 10g of vannamei shrimp, wash with ice water, drain the water, soak in 40g, 4 ℃ preservation and deodorization liquid for 3 hours, and obtain deodorization shrimp; The sodium bicarbonate solution of 0.005g / ml is composed of 3:1 by weight with the natural deodorizing liquid;

[0078] Solid deodorization of scallop pillars: take 10g of scallop pillars of Chlamys farreri, wash them with ice water, drain the water, add them to 40g of soaking solution A, soak at 8°C for 3 hours, and obtain deodorized scallop pillars; the soaking solution A includes the following Components in percentage by weight: 30% of natural deodorizing liquid, 0.2% of edible gelatin, and the balance is water;

[0079] Rehydration and deodorization of algae: Take 2.5g of dried kelp and add 12.5g of soaking solution B, soak at 8°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com