A porous ultra-short implant filled with degradable ceramics and its preparation method

A technology of implants and ceramic bodies, which is applied in the fields of dental implants, medical science, orthodontics, etc., and can solve problems such as loosening and sinking of ultra-short implants, weakened strength of ultra-short implants, and insufficient alveolar bone height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

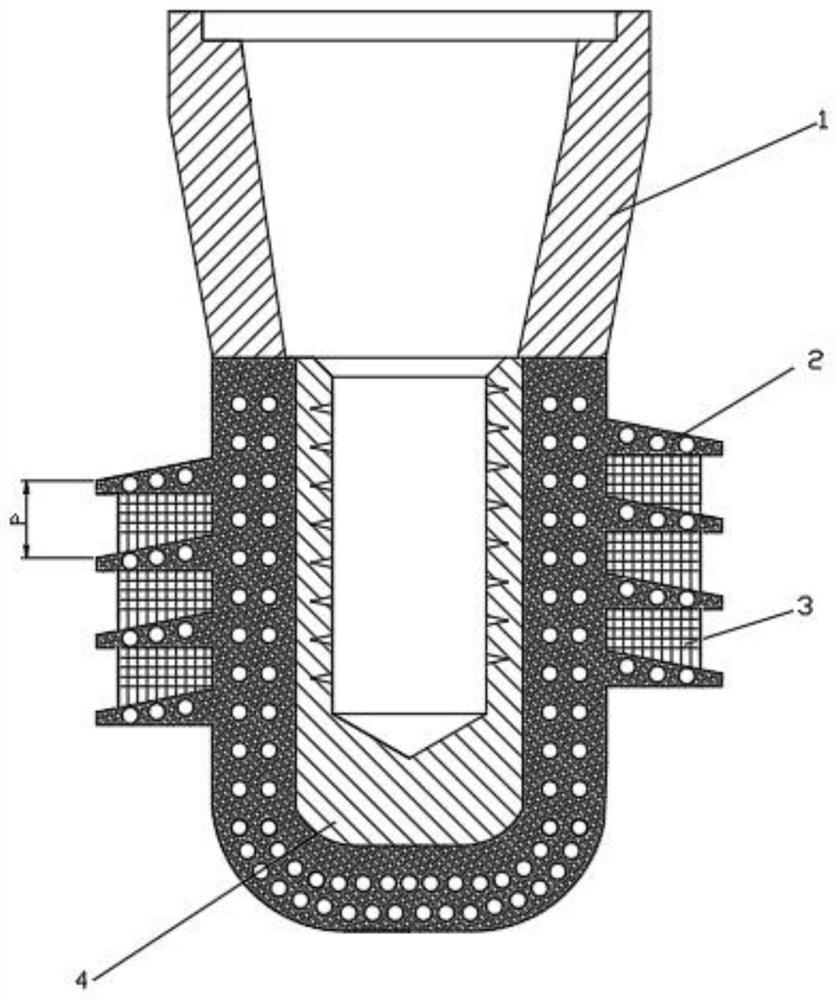

[0017] refer to figure 1 , a porous ultra-short implant filled with degradable ceramics, comprising a neck 1, a body connected to the lower part of the neck 1, the body is composed of an outer body 2 and an inner body 4, the outer body 2 is a porous structure interconnected, The porous structure is filled with degradable bone cement to ensure the structural integrity of the ultra-short implant and improve the success rate of implantation; the inner body 4 is a solid and dense part, and the inner body 4 is provided with internal threads, which are connected with the abutment Cooperate connection, the outside of the outer body 2 is provided with external thread, the external thread is a fine thread structure distributed along the body, the thread structure is a zigzag thread, the thread form is spiral rising or fish fin type, and the pitch P is 0.8- 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com