Adsorption and separation regulation type supercritical fluid extraction equipment

A supercritical fluid, adsorption and separation technology, applied in co-current extraction, solid solvent extraction, solvent extraction, etc., can solve the problems of difficulty in maximizing the extraction rate, waste of effective substances, and insufficient separation, etc., to achieve gentle and painless extraction adjustment Effects of contamination, improved recovery, and improved extraction efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

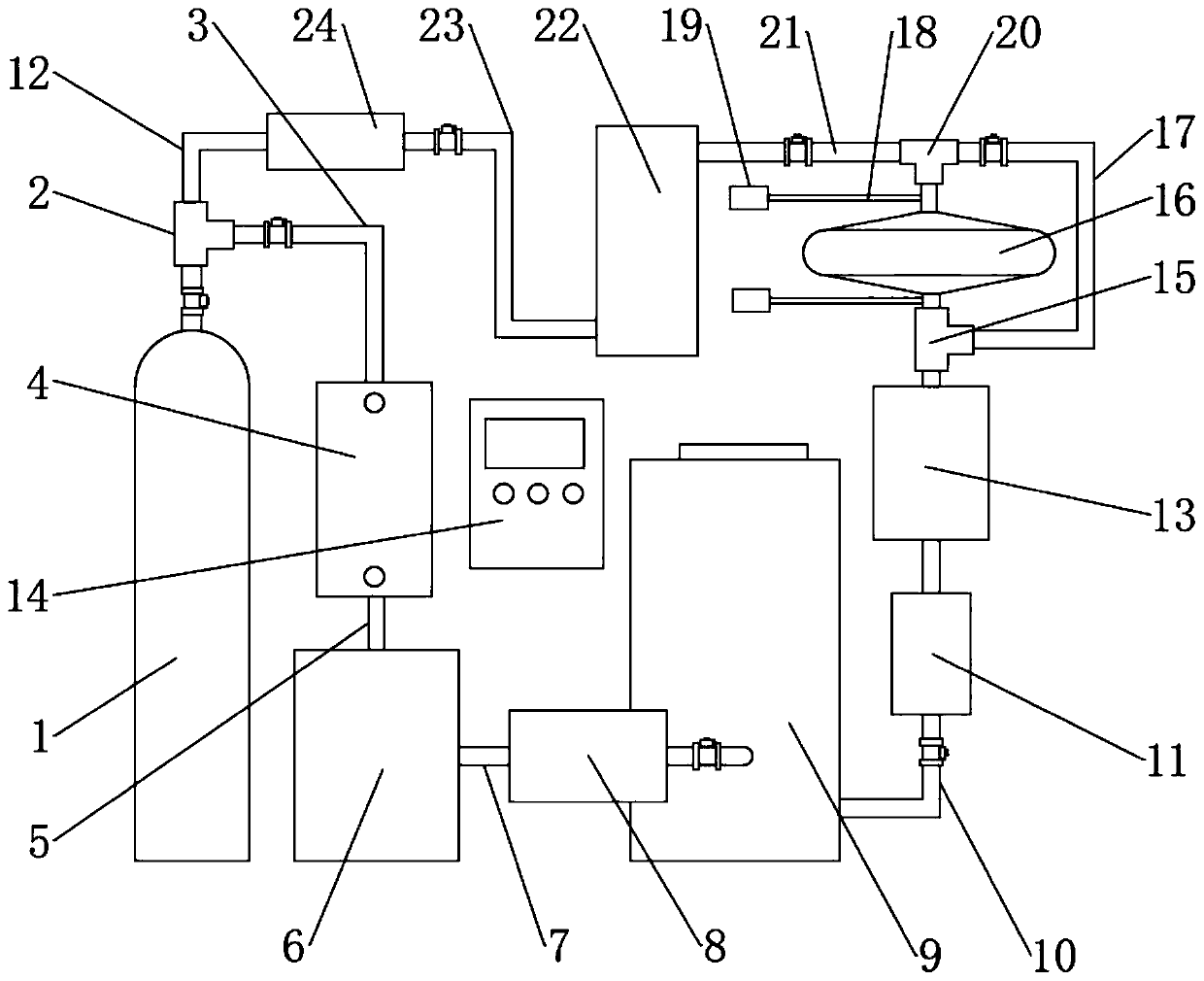

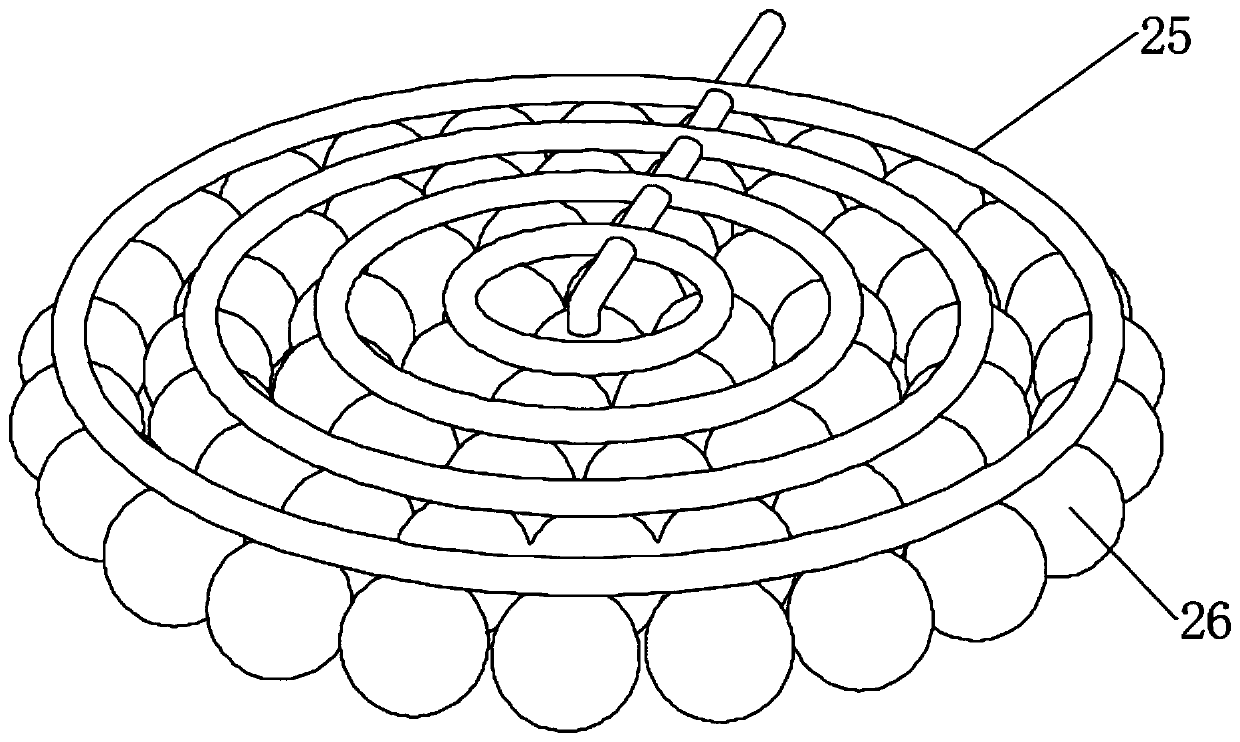

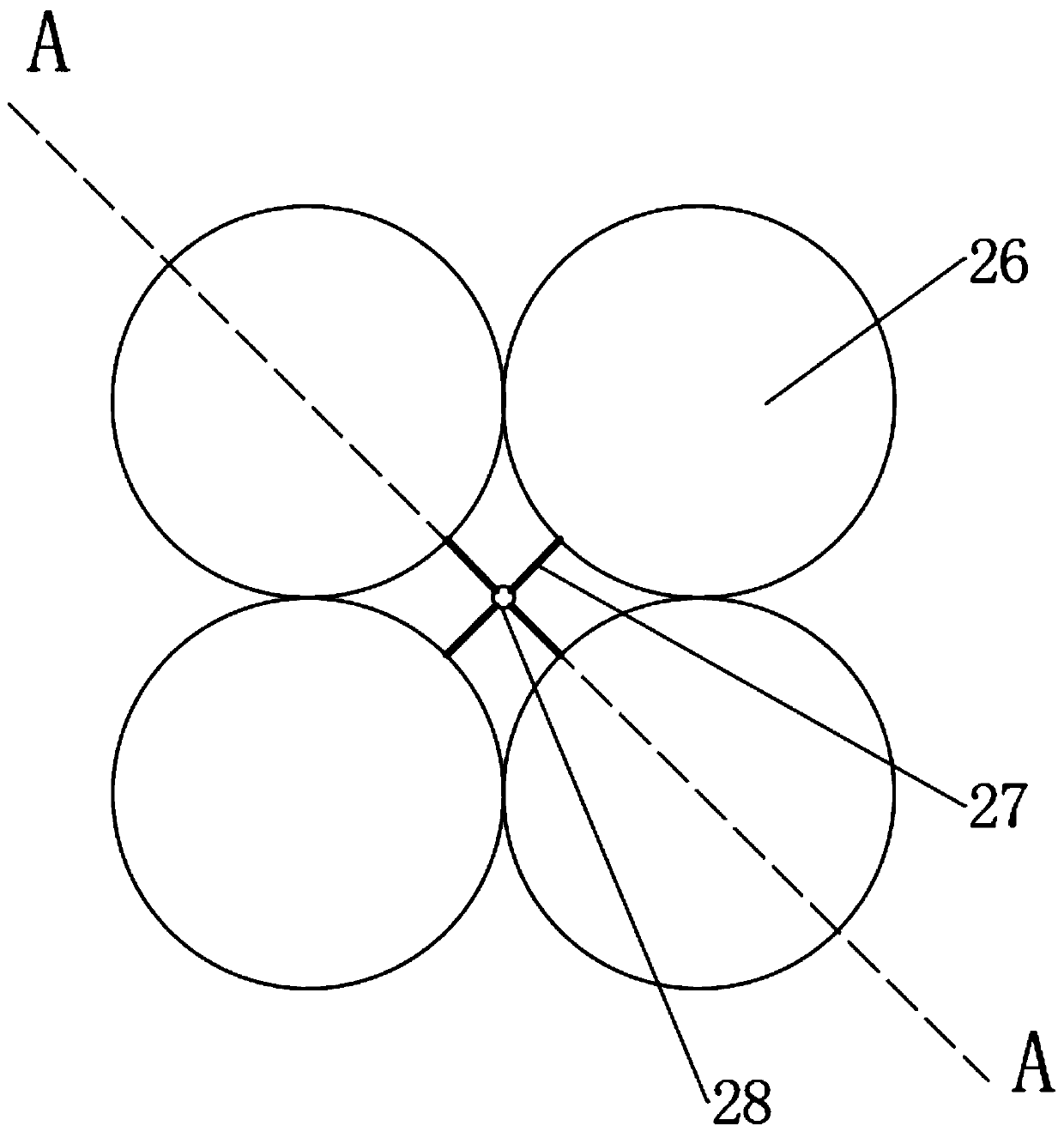

[0046] see figure 1 , a kind of supercritical fluid extraction equipment of adsorption separation control type, comprising storage tank 1 and control box 14, the inlet end of storage tank 1 is fixedly connected with the first three-way pipe 2, and the right end of the first three-way pipe 2 is fixedly connected with the first The connecting pipe 3, the first connecting pipe 3 is fixedly connected with the condensation tank 4, the condensation tank 4 is fixedly connected with the second connecting pipe 5, the second connecting pipe 5 is fixedly connected with the pressurized tank 6, and the pressurized tank 6 is fixedly connected with the third The communication pipe 7, the third communication pipe 7 is fixedly connected with the heating tank 8, the heating tank 8 is fixedly connected with the extraction kettle 9, the outlet end of the extraction kettle 9 is fixedly connected with the fourth communication pipe 10, the fourth communication pipe 10 is fixedly connected with the pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com