Ultra-high temperature resistant bag type dust remover

A bag-type dust collector and ultra-high temperature technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of filter bag damage, can not continue to use, filter bag easily damaged, etc., to achieve service life Long, enhanced cleaning effect, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

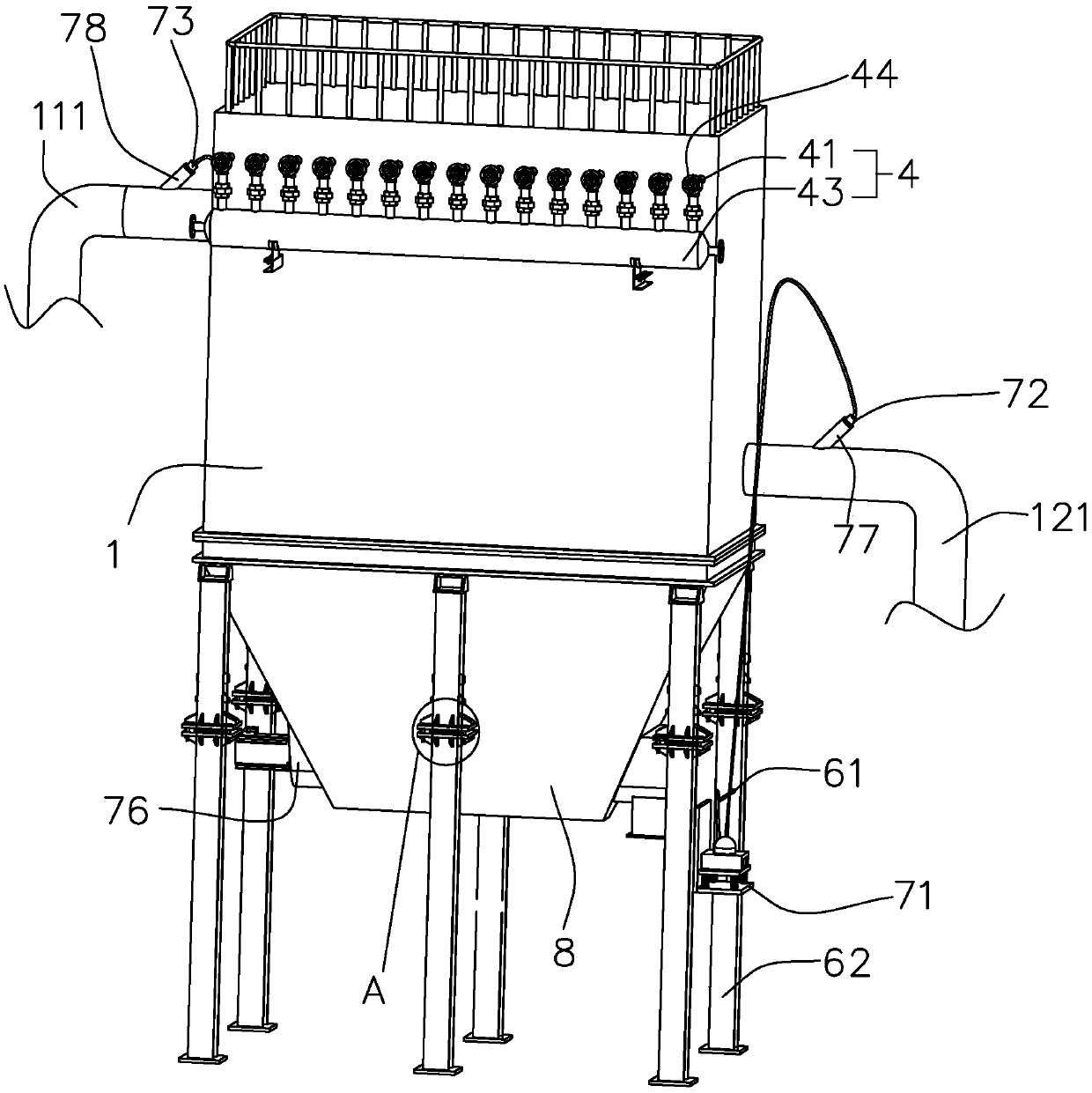

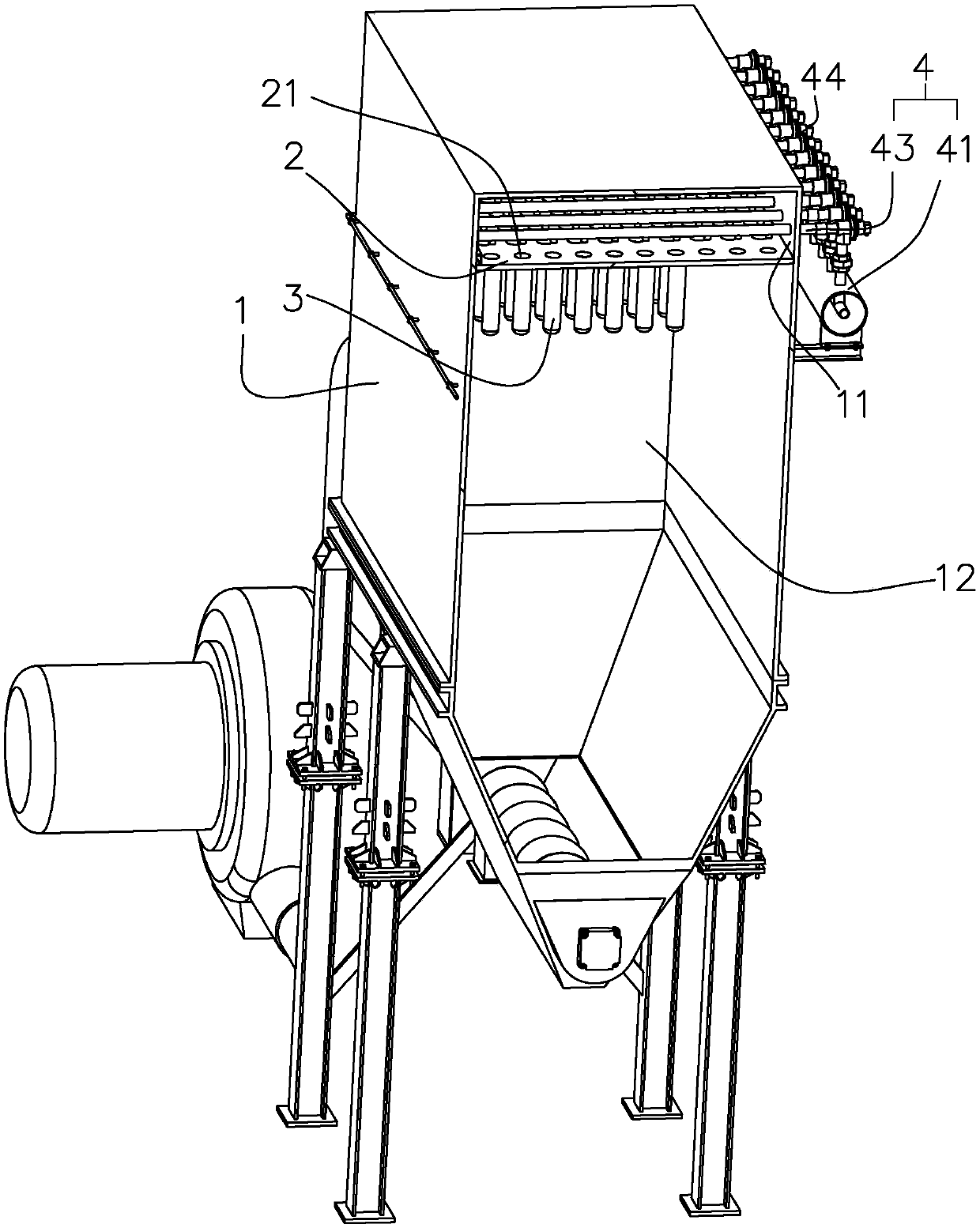

[0040] An ultra-high temperature resistant bag filter, such as figure 1 , including the dust collector body 1, the four corners of the lower end of the dust collector body 1 are provided with supporting columns 61 extending downward, and the supporting columns 61 support the dust collector body 1.

[0041] Such as figure 1 When the dust collector body 1 filters the exhaust gas with a high temperature, the dust collector body 1 will expand and deform when heated, resulting in a decrease in the safety of the dust collector body 1 . The support column 62 is connected to the bottom of the support column 61 through the anti-expansion device. When the support column 61 is heated and expanded by the anti-expansion device, it is not easy to stagger with the support column 62 due to expansion, causing the dust collector body 1 to tilt or even collapse. Case.

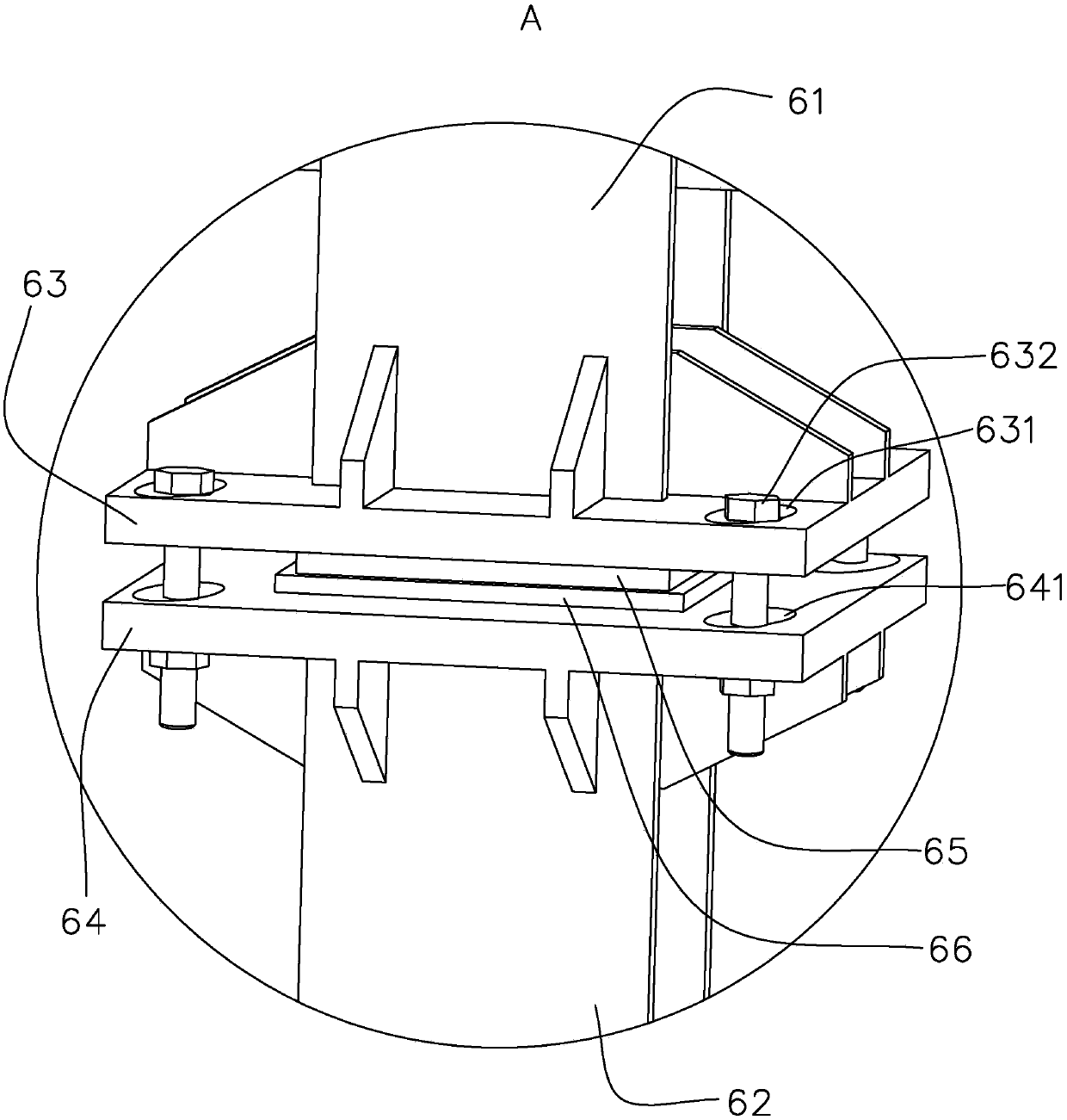

[0042] Such as figure 2 , the anti-expansion device comprises a transverse first anti-expansion plate 63, the first anti-expa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap