Remote bolt dismantling and automatic grabbing tool and using method thereof

A long-distance, bolt technology, used in manufacturing tools, hand-held tools, manipulators, etc., can solve the problem of lack of special tools for long-distance bolt removal, and achieve the effect of strengthening stability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

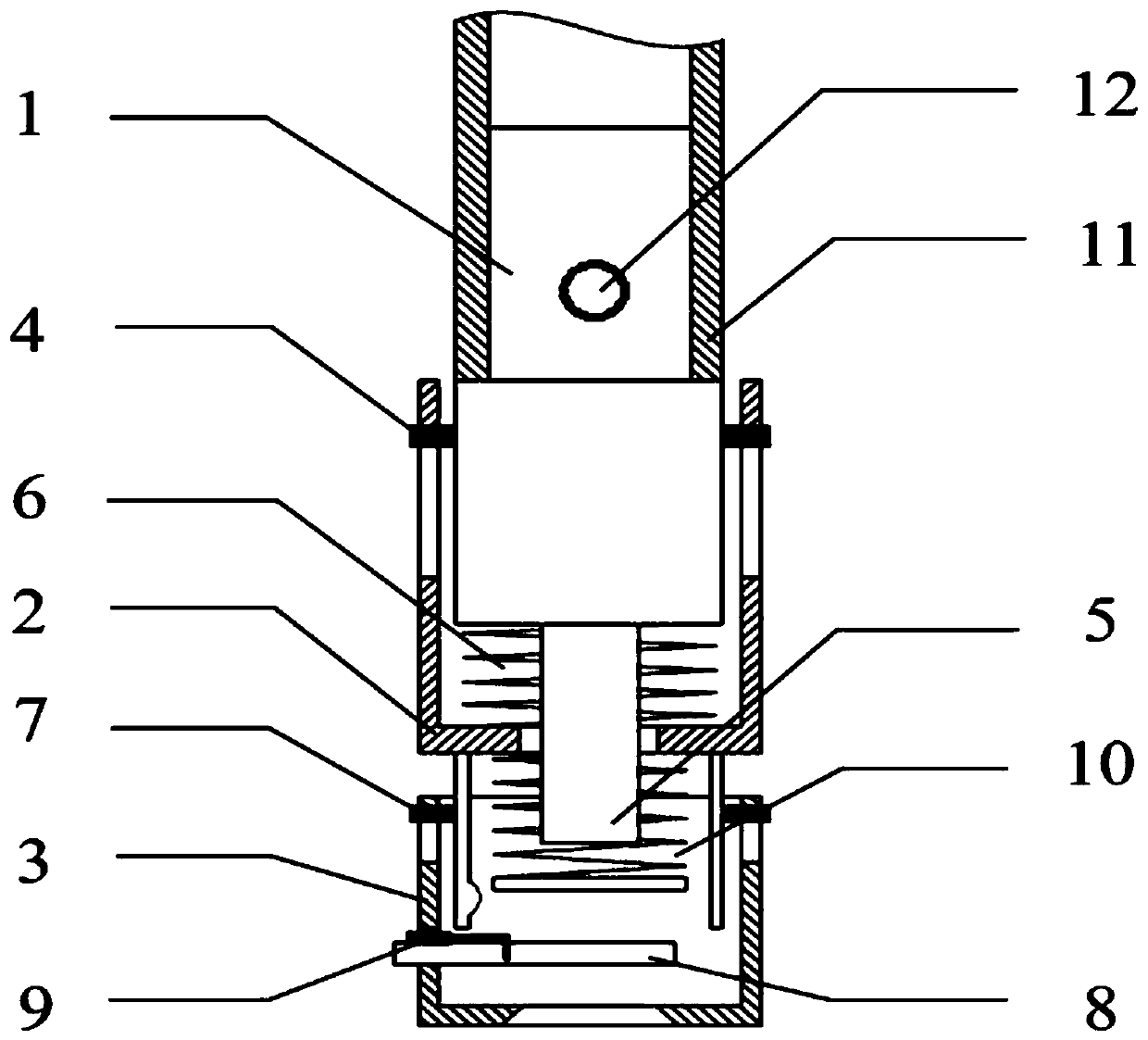

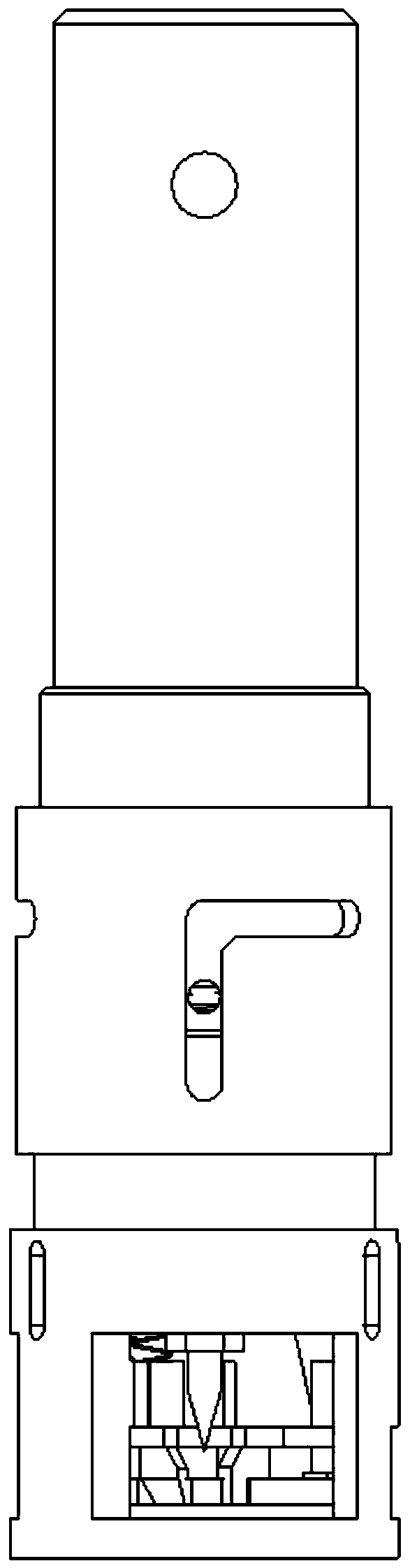

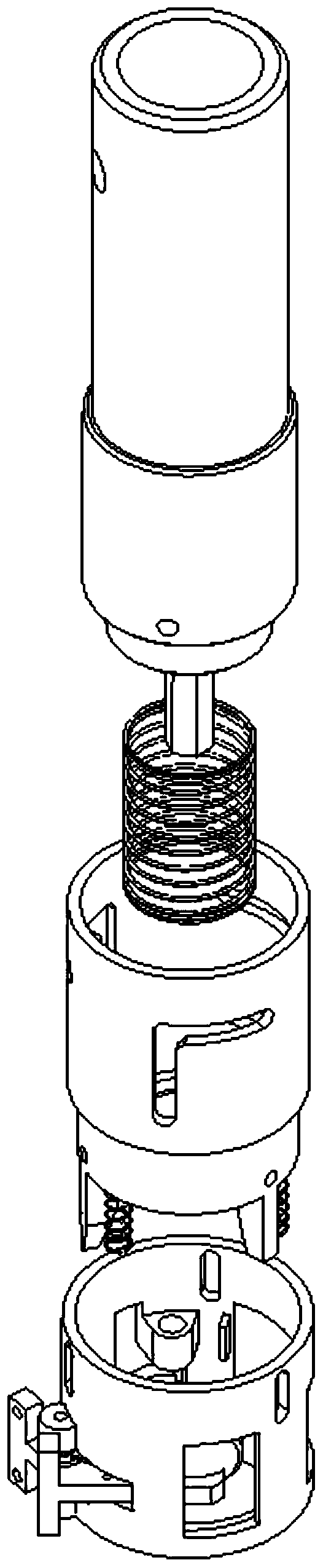

[0034] This embodiment provides a long-distance bolt removal and automatic grabbing tool, its structure is as follows figure 1 , figure 2 and image 3 As shown, it is mainly composed of three parts: main body 1, transition sleeve 2 and jacket 3, all of which are processed by stainless steel.

[0035] The main body 1 includes an intermediate body and a connecting body at the end. The intermediate body and the connecting body are two cylindrical structures with different diameters. The diameter of the intermediate body is greater than the diameter of the end; The length is determined according to the actual operation distance on site; the upper end of the connecting body has a round hole, and the main body 1 and the long rod 11 are connected together by the pin 12 .

[0036] The intermediate outer wall of the main body 1 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com