Ceramic tile mold and tile billet manufactured by using same

A ceramic tile and mold technology, applied in ceramic molding machines, molds, manufacturing tools, etc., can solve the problems affecting the aesthetics of tile paving, and achieve the effect of improving aesthetics and high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

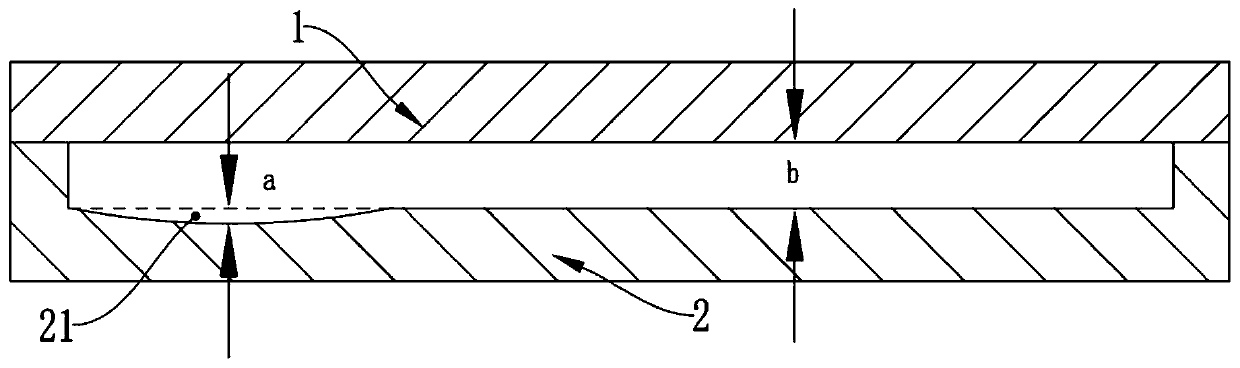

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0027] A ceramic tile mold, suitable for ceramic tile pressing equipment for dry stamping, comprising an upper mold 1 and a lower mold 2, the upper mold 1 and the lower mold 2 are fastened to form a mold cavity, and the lower mold 2 The surface is depressed downward to form at least one sinking position 21, and the width of the sinking position 21 is the same as the width of the mold cavity, and the sinking position 21 is close to the side of the lower mold 2 in the kiln exit direction .

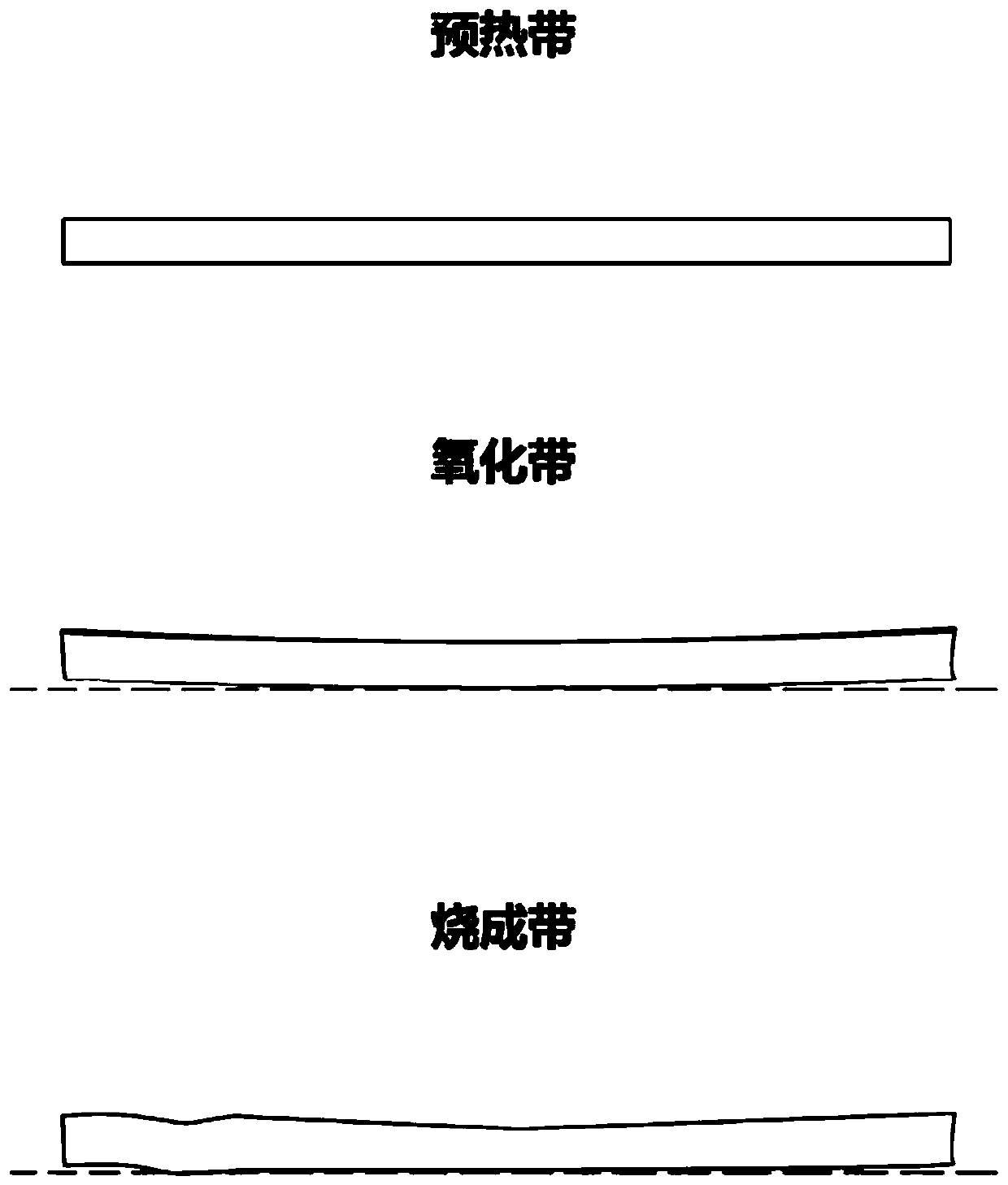

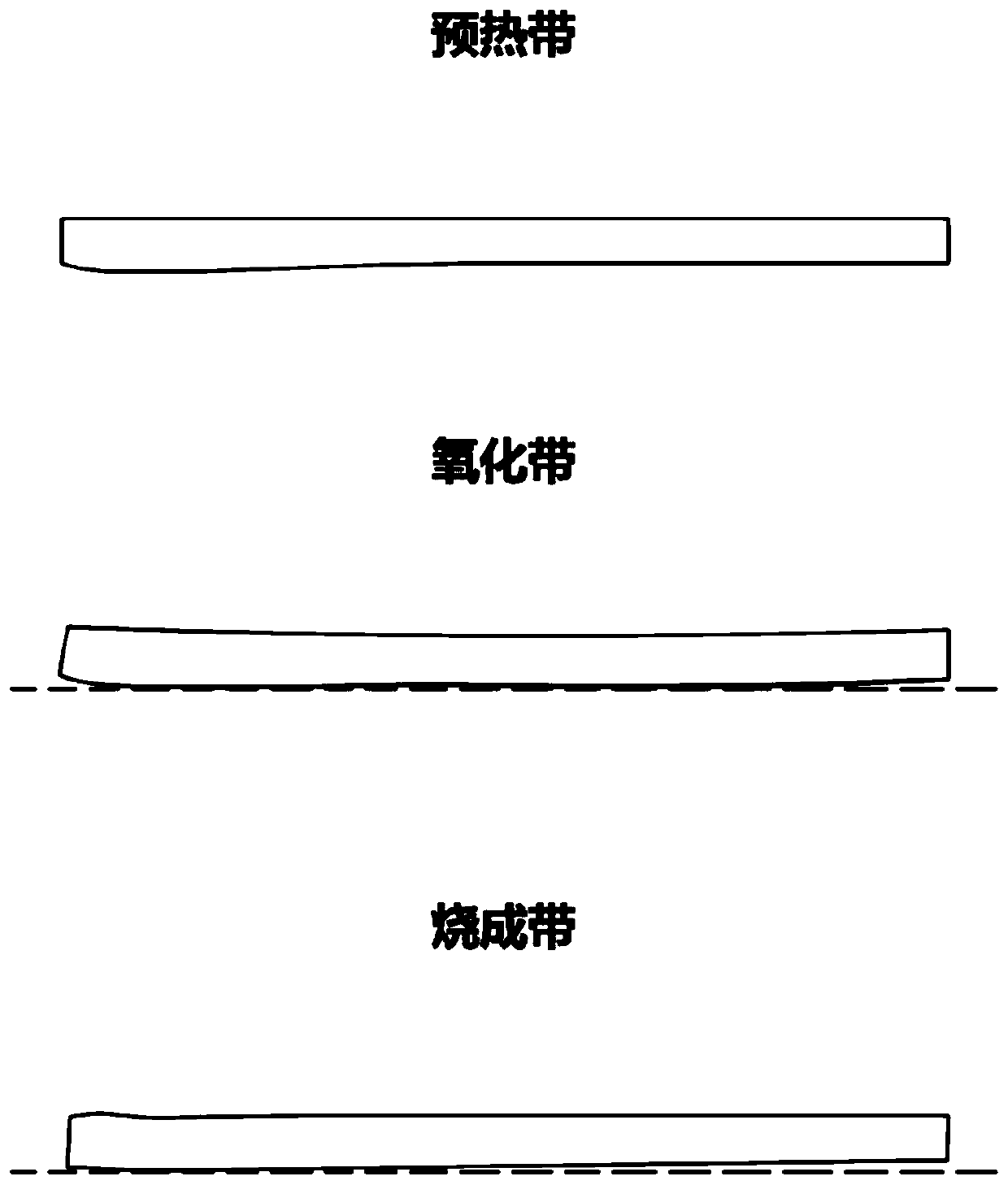

[0028] The dry stamping forming process of architectural ceramics is to pour the ground ceramic powder into the ceramic brick mold of the pressing equipment after dry granulation, and then press it into a brick by an extrusion molding machine. The extruding surfaces of the upper mold and the lower mold of the exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com