Pulsed jet rock debris washing tool

A technology of pulse jet and cleaning tools, which is applied in the direction of flushing boreholes, boreholes/well components, earthwork drilling and mining, etc. It can solve the problems of stuck drill cleaning efficiency, easy deposition of cuttings, and unsatisfactory cleaning effect of cuttings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

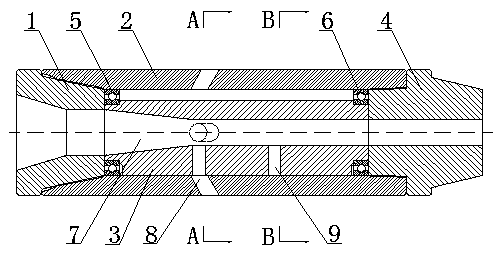

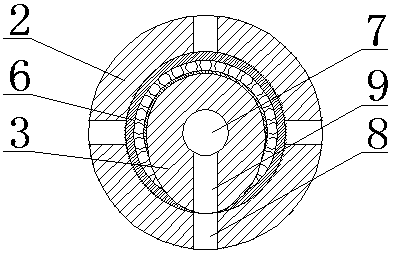

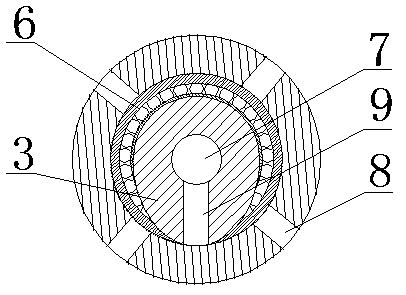

[0021] The pulse jet cuttings cleaning tool is composed of an upper joint 1, a housing 2, a central pipe 3 and a lower joint 4. The housing 2, the upper joint 1 and the lower joint 4 are respectively cylindrical, and the inner hole of the upper joint is in the shape of a variable diameter. One end of the shell 2 is threaded with an upper joint 1, and the other end of the shell 2 is threaded with a lower joint 4. After the shell 2 is threaded with the upper joint 1 and the lower joint 4, it is in a straight cylindrical shape. During work, the upper joint 1 and the lower joint 4 are used to connect the drill pipe, and the lower joint 4 is used to install the drilling tool; when the drilling fluid flows from the large-diameter end of the inner hole of the upper joint 1 to the narrow The top joint 1 will suppress the pressure of the drilling fluid, so that the liquid flow rate of the drilling fluid in the top joint 1 will be accelerated, thereby acting on the drilling tool.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com