Rock creep triaxial test system and method capable of continuously acting in water environment

A triaxial test and water environment technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of easy damage of constant flow pumps, differences in compressive strength, high requirements for constant flow pumps, etc. problem, to achieve cost reduction and good expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

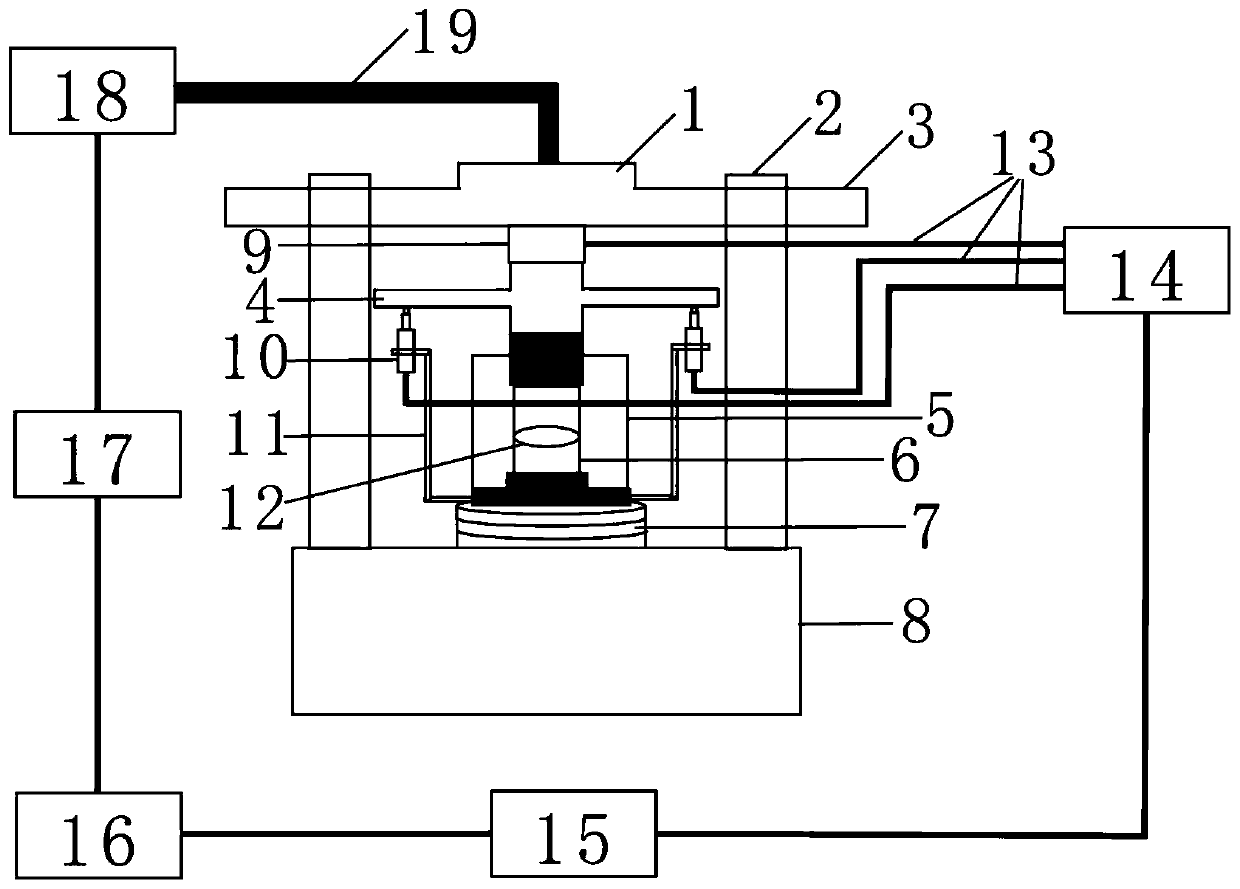

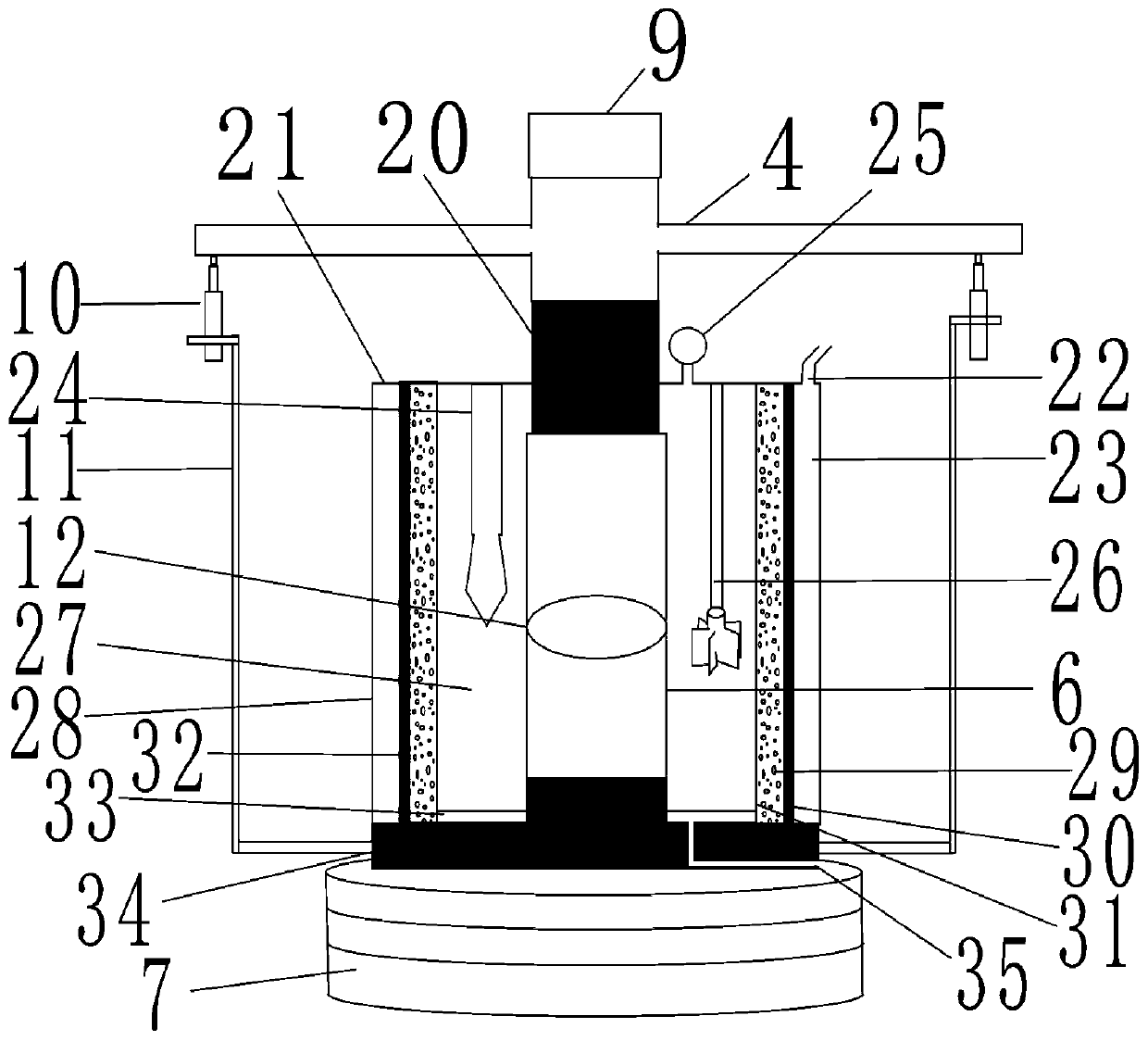

[0031] A triaxial test system for rock creep under continuous water environment, including: pressurized cylinder 1, pillar 2, beam 3, water environment confining pressure system 5, testing machine base 8, dynamic stress and strain acquisition system 14, computer 15, Digital controller 16, servo controller 17, hydraulic source 18, oil delivery pipe 19, described pressurization cylinder 1 is connected with described crossbeam 3, and described crossbeam 3 is supported on the described testing machine base 8 by pillar 2, and described base The water environment confining pressure system 5 is arranged between 8 and the beam 3, and the dynamic stress and strain collection system 14 is connected with the water environment confining pressure system 5, and the dynamic stress and strain collection system 14 is sequentially connected with the computer 15, A digital controller 16, a servo controller 17, a hydraulic source 18, and an oil delivery pipe 19 are connected.

[0032]Further, the...

Embodiment 2

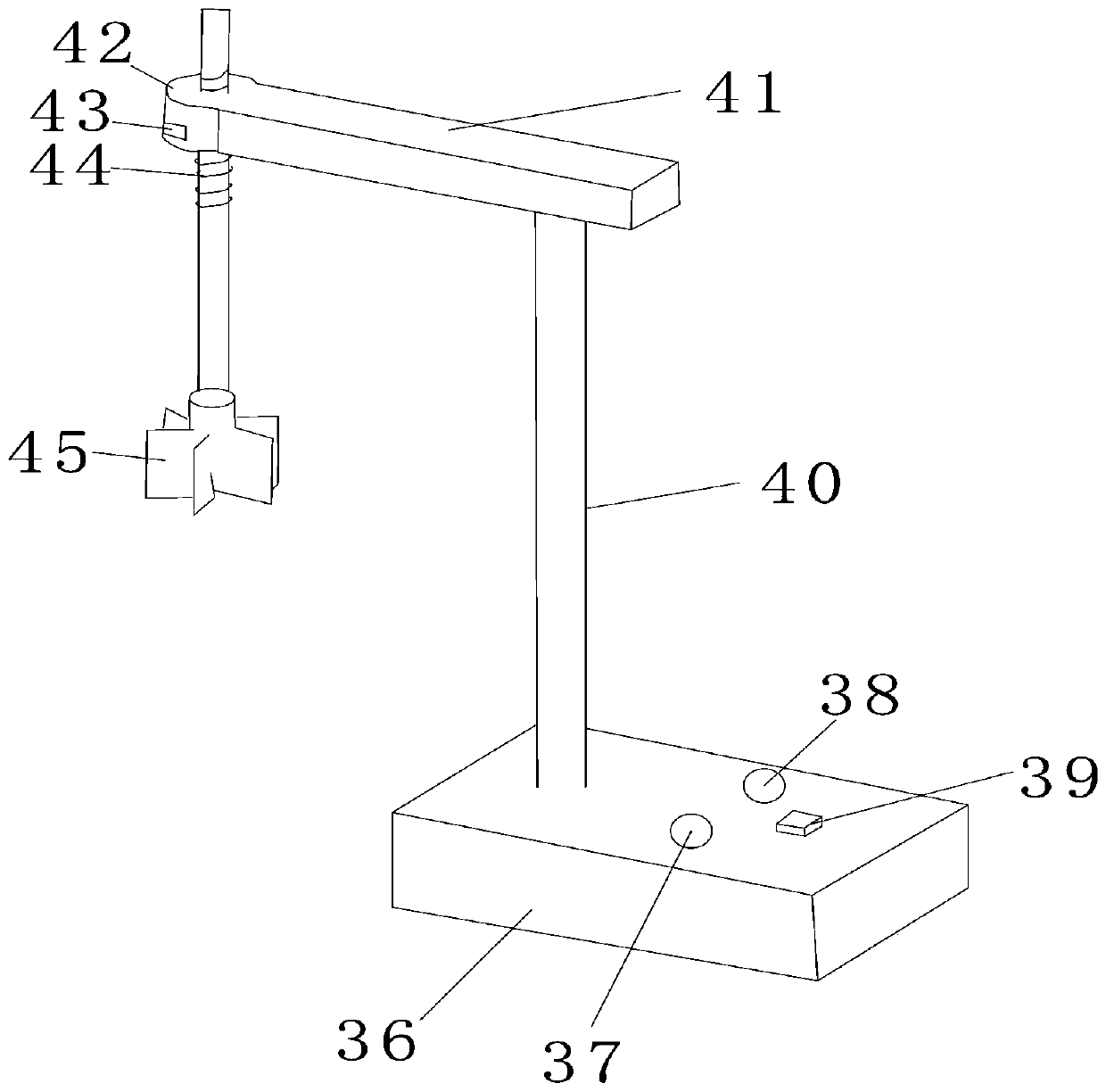

[0047] A rock creep triaxial test system under continuous water environment action, the system includes axial loading system, collection system, water environment confining pressure system and automatic stirring system. It is suitable for simulating and reproducing the whole process analysis of rock creep damage and cracking in flowing / static water and other water environments containing chemical components.

[0048] (1) Axial loading system

[0049] The axial loading system consists of a pressurized cylinder 1, a pillar 2, a beam 3, a pressure head 4, an adjustment pad 7, a testing machine base 8, a computer 15, a digital controller 16, a servo controller 17, a hydraulic source 18, and an oil pipeline 19 .

[0050] (2) Acquisition system

[0051] The acquisition system is composed of force sensor 9, lvdt displacement sensor 10, lvdt frame 11, circumferential strain gauge 12, sensor data line 13, dynamic stress and strain acquisition system 14, pressure gauge 25, and PH test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com