Instant online instrument verification and diagnosis method through optimal support vector machine algorithm

A technology of support vector machine and diagnosis method, which is applied in the field of real-time online instrument calibration and diagnosis, and can solve problems such as the timing of delayed processing, the inability to accurately judge the measured value of the instrument in time, and the inability to verify the accuracy of the data and whether the flow network system is running normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with embodiment the present invention is further described.

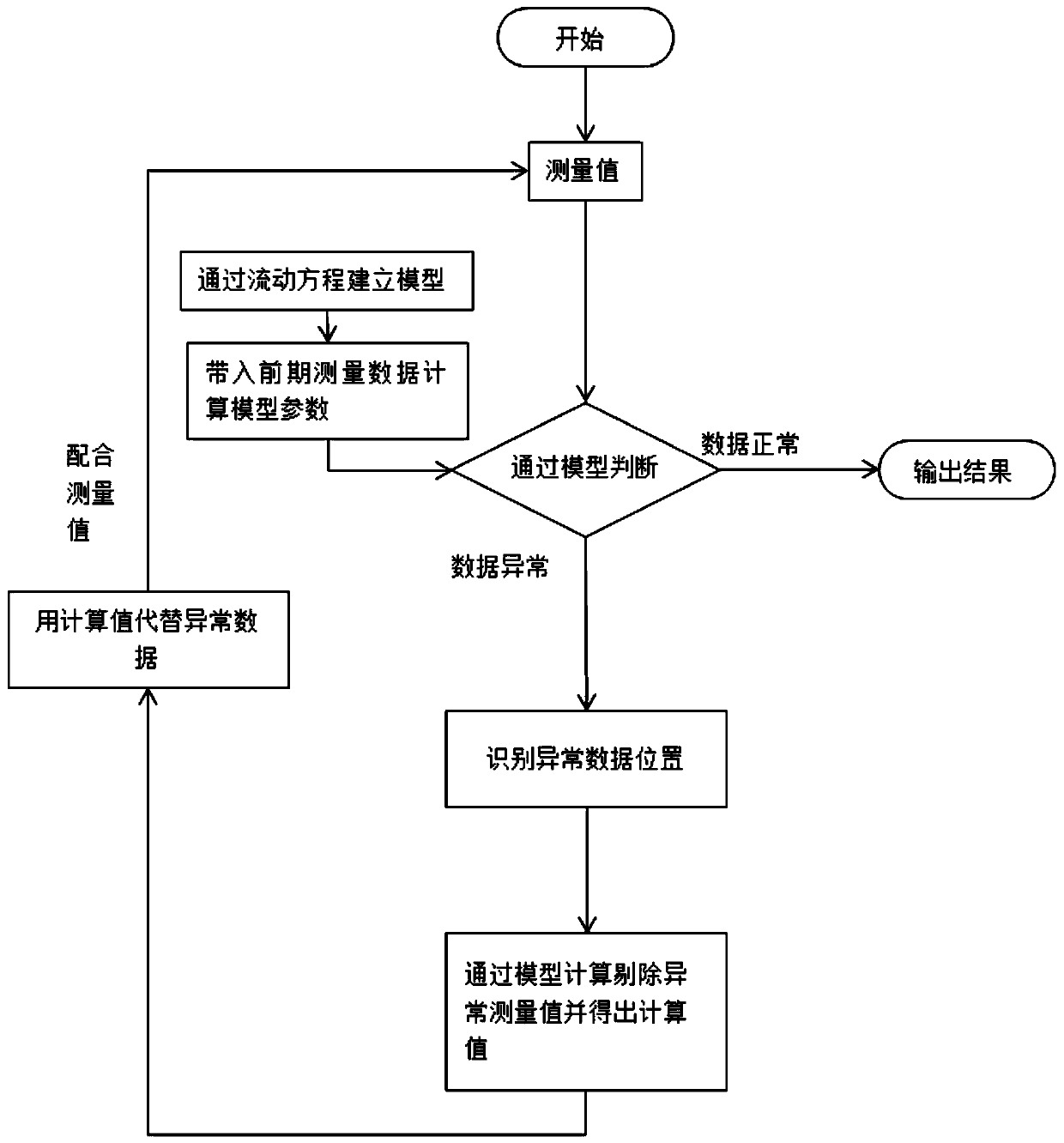

[0058] Such as figure 1 As shown, a real-time online instrument calibration and diagnosis method through the optimal support vector machine algorithm, including the following steps:

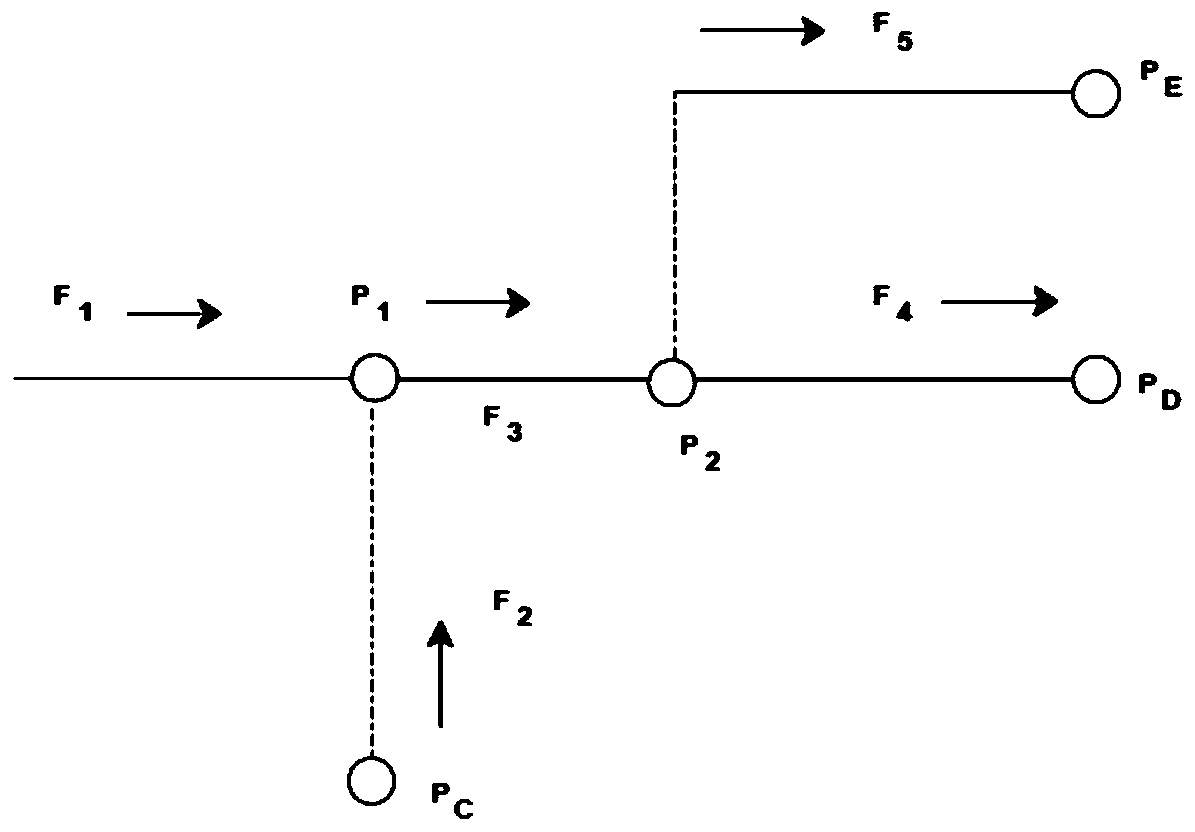

[0059] S1. Through fluid mechanics continuity equation, momentum equation and energy equation, build flow network model, including flow channel model and equipment component model.

[0060] Through the fluid mechanics continuity equation, momentum equation (Navier-Stokes equation) and energy equation, the flow network model is built by using the node method. For large flow networks, the modeling process can be simplified by simplifying large flow networks or systems into multiple small flow networks or systems.

[0061] In order to obtain a fluid network model that is easy to calculate, it is assumed that the fluid only flows uniformly along the direction of the conduit, and responds very quickly to change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com