High-stiffness and high-damping local resonance unit for constructing acoustic metamaterial structure

An acoustic metamaterial and local resonance technology, which is applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of poor stiffness-damping comprehensive performance, weak anti-interference and protection ability, and narrow working frequency band, etc., to achieve strong protection function and overcome stiffness. - Poor comprehensive damping performance and the effect of broadening the low frequency resonance frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

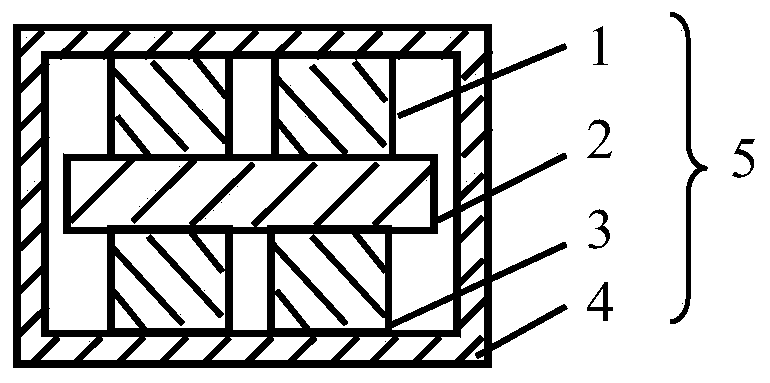

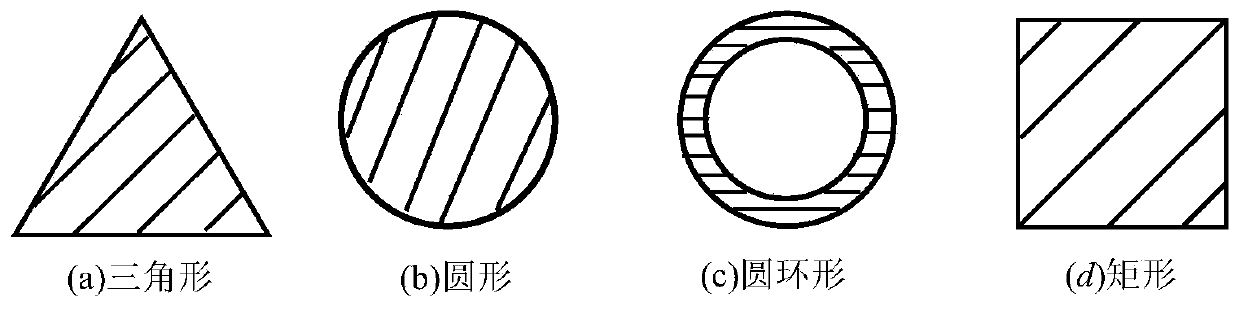

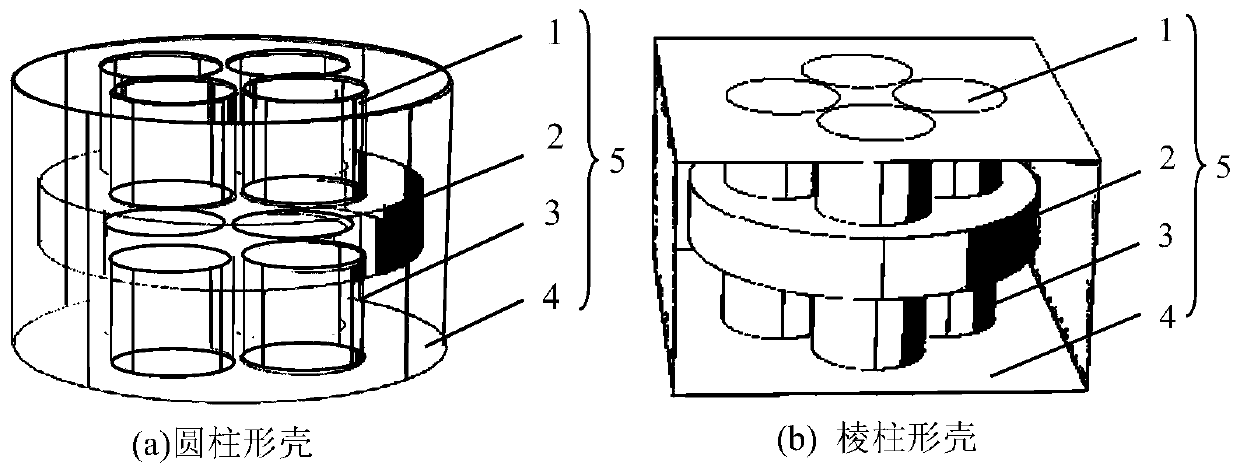

[0043] The local resonance unit adopts the form of a single vibrator. The structural form of the vibrator elastic element 1 and the vibrator elastic element 3 is cylindrical, and its cross-sectional shape is circular, and its diameter and thickness are 8mm×7.6mm; the structural form of the vibrator rigid element 2 is columnar. , its cross-sectional shape is circular, its diameter and thickness are 27mm×5mm; the support and protection structure 4 adopts a cylindrical shell, the outer diameter and height of the shell are 32mm×20mm, and the thickness of the shell is 1mm; The elastic element 1 and the vibrator elastic element 3 are made of silicon rubber, the vibrator rigid element 2 is made of stainless steel, the support and protection structure 4 is made of PAL, and the total weight of a vibrator unit is about 30g. The above-mentioned local resonance units are periodically arranged on a reinforced panel with a length, width and thickness of 850mm×850mm×2.5mm to form a metamateri...

Embodiment 2

[0045] The parameters of the vibrator unit 5 in the second embodiment are the same as those in the first embodiment, and the fixed mounting surfaces of the vibrator unit 5 are the circumferential surface of the vibrator and the surface perpendicular to the axial direction of the vibrator.

[0046] The damping effect of the structure in preferred embodiment one of the present invention refers to Figure 7 It can be seen that the metamaterial plate structure of the vibrator structure of the present invention has a good vibration suppression effect, and the average longitudinal wave vibration attenuation in 100Hz-1000Hz exceeds 10dB, and the average longitudinal wave vibration attenuation in 280Hz-500Hz exceeds 20dB. From the resonance mode of the vibrator unit 5 in the preferred embodiment 2 of the present invention, it can be known that when the surface perpendicular to the axial direction of the vibrator is used as the fixed installation surface, the vibrator unit 5 has a shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com