Welding material warehouse for power station, welding material storage system and working method

A technology for welding consumables and power stations, applied in the field of welding consumables warehouse, can solve the problems of increased production cost per unit, unfavorable protection and use of welding consumables, long construction time period, etc. The effect of factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

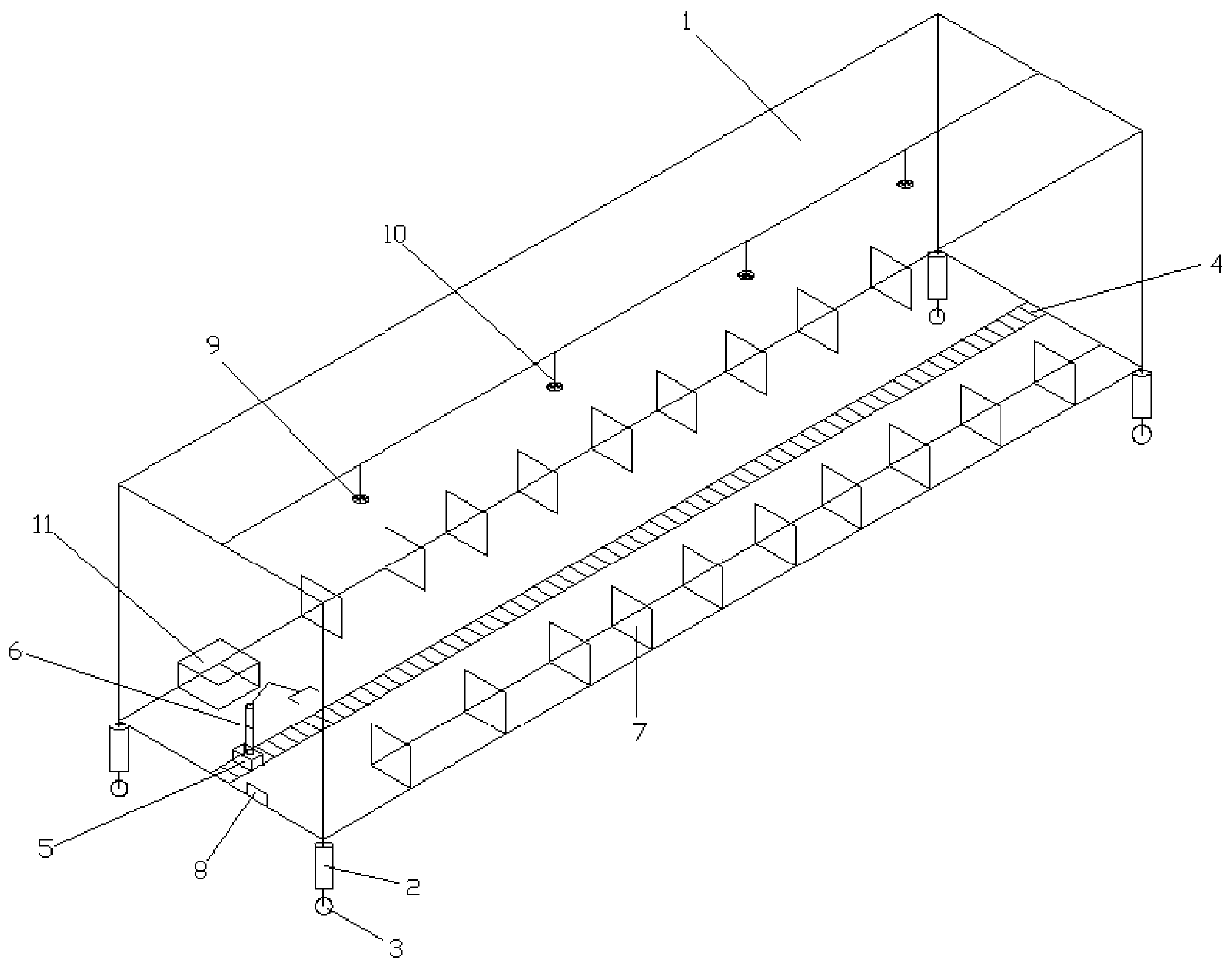

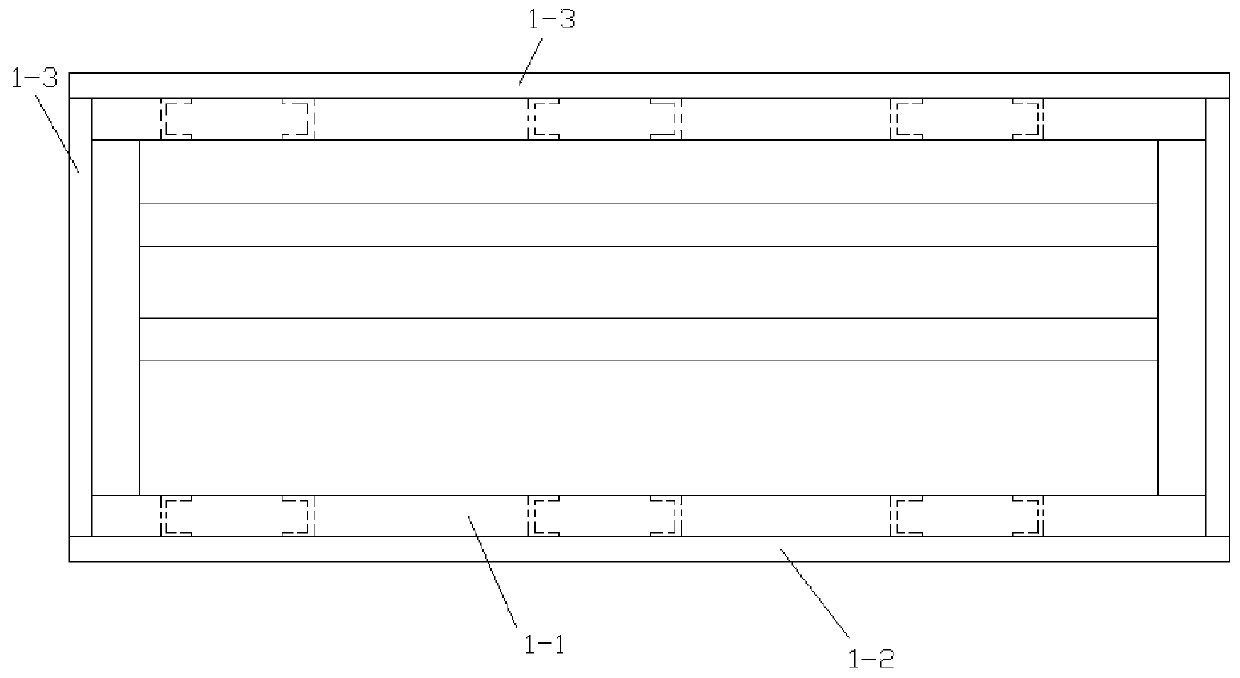

[0050] This embodiment discloses a welding material storage system, such as Figure 5 As shown, it includes a welding material baking room 13 and the welding material storage for the power station described in Embodiment 1, the welding material baking room is provided with a second opening 14, the first opening of the welding material storage for the power station and the welding material baking room A transmission mechanism is provided between the second openings, the transmission mechanism adopts a belt transmission mechanism 15, and welding material baking equipment is arranged in the welding material baking room, and the welding material baking equipment can use existing equipment, and will not be described in detail here , the baked welding consumables can be transported into the welding consumables warehouse body for storage through the belt transmission mechanism.

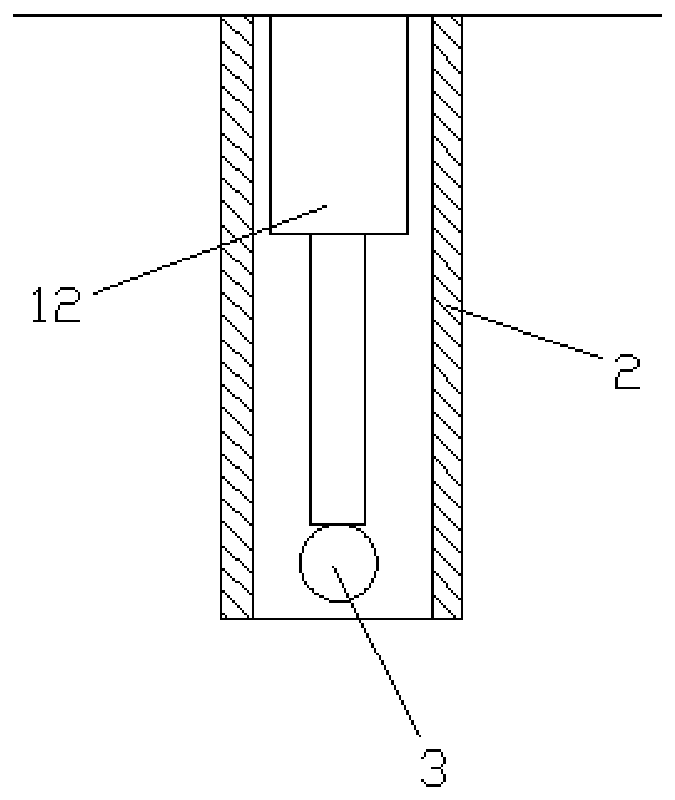

[0051] The end of the belt transmission mechanism located on one side of the welding consumables baking c...

Embodiment 3

[0054] This embodiment discloses a working method of the welding consumable storage system: the welding consumables are baked in the baking chamber, and the baked consumables are placed on the belt transmission mechanism, and the belt transmission mechanism transmits the belt. When passing through the industrial camera, the industrial The camera collects the image of the welding material and transmits it to the industrial computer, and the industrial computer transmits it to the upper computer for display. The operator uses the picture displayed by the upper computer to judge the specification and model of the welding material, and uses the upper computer to start the printer to print the welding material of the corresponding specification. The corresponding two-dimensional code picture, after the picture is printed, the operator pastes the picture on the surface of the welding material, and the welding material continues to be transported to the inside of the welding material w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com