Preparation method of copper nanowire toughened root-blocking waterproof membrane cladding material

A technology of copper nanowires and waterproof membranes, which is applied to roofs using flexible materials, building insulation materials, roofs, etc., and can solve problems such as root resistance performance that cannot meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

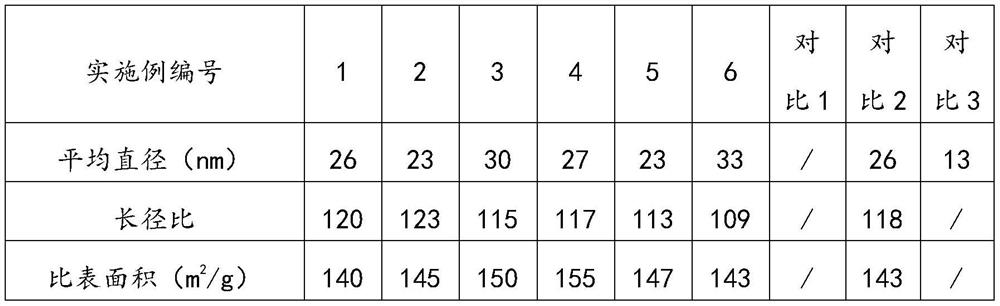

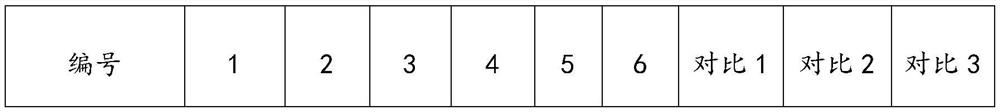

Examples

Embodiment 1

[0024] Step 1: Use 5 parts by weight of copper chloride and 5 parts by weight of ethylenediaminetetraacetic acid to prepare a solution, add 4 parts by weight of sodium hexadecylsulfonate into the solution and stir evenly, and finally add 5 to 10 parts by weight of Parts of sodium citrate, stir to mix well. The mixed solution was irradiated with a pulsed laser with a power of 10 W, a frequency of 20 Hz, and a processing time of 10 minutes. Copper nanowires were obtained by centrifugation under vacuum.

[0025] Step 2: Disperse 10 parts by weight of copper nanowires into a 1:1 mixture of 100 parts by weight of distilled water and ethanol, add 15 parts by weight of polyethylene glycol trimethoxysilyl propyl ether, control the reaction time for 8 hours, and the temperature at 40°C to obtain the modified copper nanowire fluid.

[0026] Step 3: The master batch of the coil cladding material is mainly prepared from the following raw materials according to the weight percentage of e...

Embodiment 2

[0028] Step 1: Use 10 parts by weight of copper acetate and 10 parts by weight of disodium edetate to form a solution, add 4 parts by weight of sodium lignosulfonate to the solution and stir evenly, and finally add 10 parts by weight of citric acid to the solution sodium, stir to mix well. By irradiating the mixed solution with a pulsed laser, the power of the pulsed laser is 50 W, the frequency is 50 Hz, and the processing time is 30 minutes. Copper nanowires were obtained by centrifugation under vacuum.

[0029] Step 2: Disperse 5 parts by weight of copper nanowires into a 1:1 mixture of 100 parts by weight of distilled water and ethanol, add 8 parts by weight of polyethylene glycol triethoxysilyl propyl ether, and control the reaction time for 4 hours , the temperature is 60° C., and the modified copper nanowire fluid is obtained.

[0030] Step 3: The masterbatch of the coil cladding material is mainly prepared from the following raw materials according to the weight perc...

Embodiment 3

[0032] Step 1: Use 5 parts by weight of copper sulfate and 10 parts by weight of ethylenediaminetetraacetic acid to form a solution, add 2 parts by weight of sodium dodecylsulfonate to the solution and stir evenly, and finally add 5 parts by weight of citric acid to the solution sodium, stir to mix well. By irradiating the mixed solution with a pulsed laser, the power of the pulsed laser is 10 W, the frequency is 50 Hz, and the processing time is 30 minutes. Copper nanowires were obtained by centrifugation under vacuum.

[0033] Step 2: Disperse 10 parts by weight of copper nanowires into a 1:1 mixture of 100 parts by weight of distilled water and ethanol, add 15 parts by weight of polyethylene glycol trimethoxysilyl propyl ether, and control the reaction time to be 6 hours and the temperature at 50°C to obtain the modified copper nanowire fluid.

[0034] Step 3: The master batch of the coil cladding material is mainly prepared from the following raw materials according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com