A hanging refractory and thermal insulation component for a large-capacity alumina co-production electrolyzer

A technology of refractory heat preservation and electrolytic cell, which is applied to electrolysis components, electrolysis process, cells, etc., can solve the problem of cracking of refractory heat preservation materials, and achieve the effect of easy lifting, preventing exposure and heat loss, and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

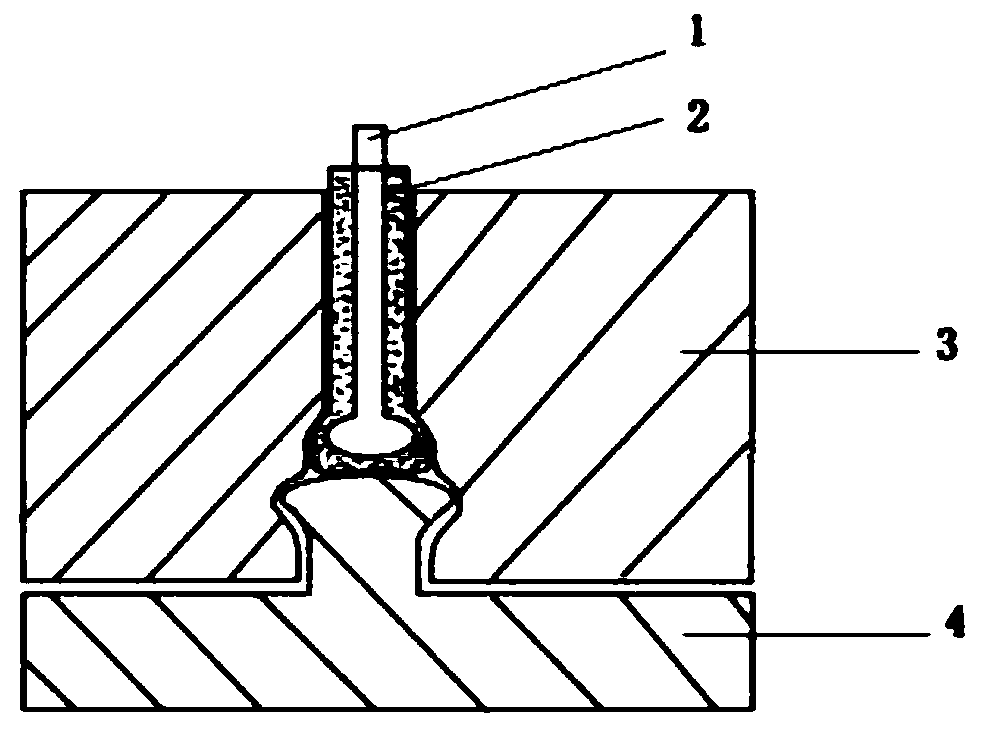

[0039] like figure 1 As shown, it is a suspension assembly of a shaped refractory material; it includes a metal rod 1, a hose 2, a thermal insulation layer 3 and a refractory layer 4, and the metal rod 1 and the aluminum electrolytic cell are isolated by the refractory layer 4;

[0040] The metal rod is wrapped with a hose 2, and the anti-expansion and anti-oxidation buffer powder mixture is filled between the metal rod 1 and the hose 2; the hose 2 is wrapped with a thermal insulation layer 3, and the lower part of the thermal insulation layer is provided with a refractory layer 4, and the thermal insulation layer 3 and The refractory layers 4 are sealed; the metal rod 1 passes through the thermal insulation layer 3 and is fitted with the thermal insulation layer 3, and the thermal insulation layer 3 is fitted with the refractory layer 4;

[0041] In this design, the refractory layer 4 is made of shaped refractory material, the lower part is a high temperature area and is clos...

Embodiment 2

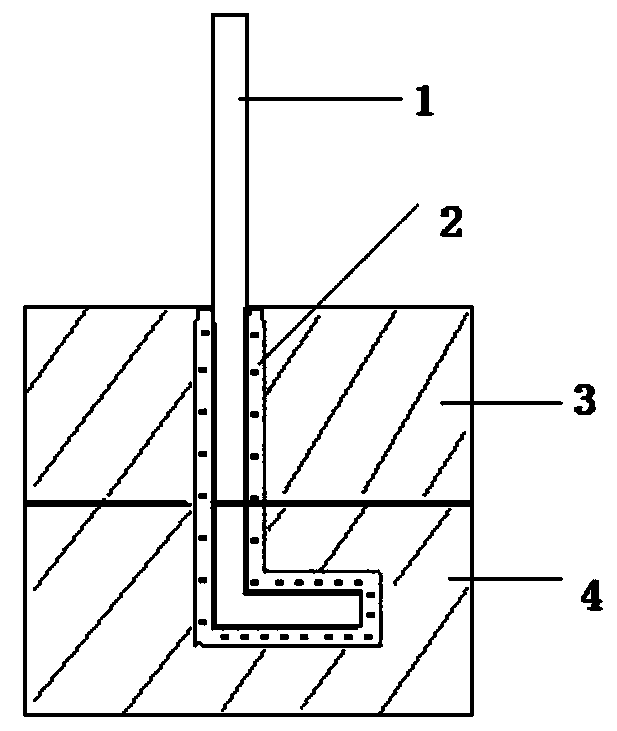

[0046] like figure 2 As shown, it is a suspension assembly of an amorphous refractory material; it includes a metal rod 1, a hose 2, an insulating layer 3 and a refractory layer 4, and the metal rod 1 and the aluminum electrolytic cell are isolated by the refractory layer 4;

[0047] The metal rod is wrapped with a hose 2, and the anti-expansion and anti-oxidation buffer powder mixture is filled between the metal rod 1 and the hose 2; the hose 2 is wrapped with a thermal insulation layer 3, and the lower part of the thermal insulation layer is provided with a refractory layer 4, and the thermal insulation layer 3 and The refractory layers 4 are sealed; the metal rod 1 passes through the thermal insulation layer 3 and extends to the refractory layer 4, and the amorphous refractory material is cast and fixed.

[0048] In this design, the refractory layer 4 is made of amorphous refractory material: first fix the metal rod and the anti-expansion and anti-oxidation buffer material i...

Embodiment 3

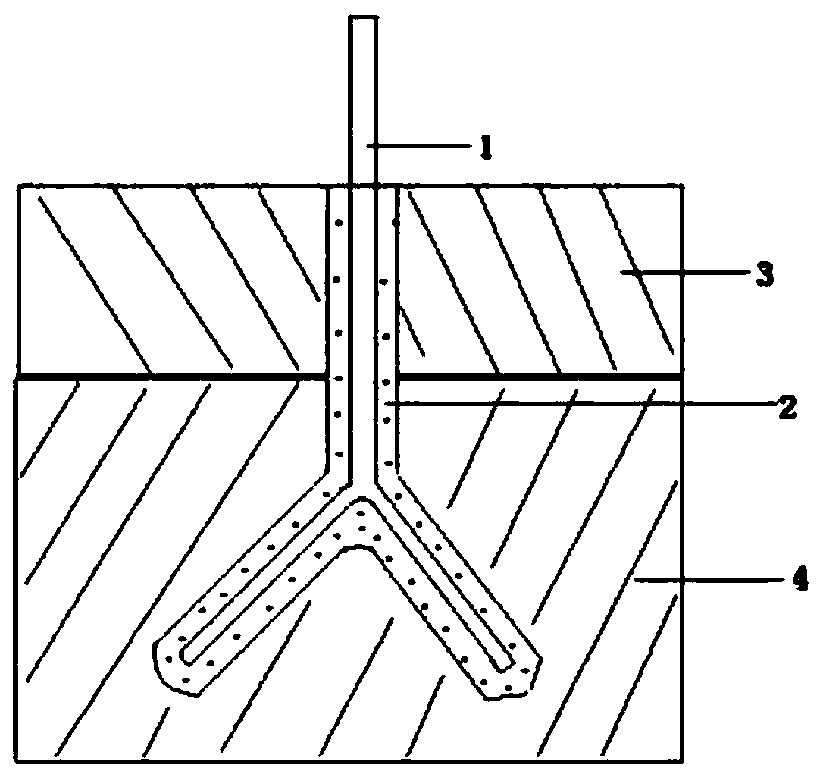

[0054] like image 3 Shown is a suspension assembly of amorphous refractory material.

[0055] It includes a metal rod 1, a hose 2, a thermal insulation layer 3 and a refractory layer 4, and the metal rod 1 and the aluminum electrolytic cell are isolated by the refractory layer 4;

[0056] The metal rod is wrapped with a hose 2, and the anti-expansion and anti-oxidation buffer powder mixture is filled between the metal rod 1 and the hose 2; the hose 2 is wrapped with a thermal insulation layer 3, and the lower part of the thermal insulation layer is provided with a refractory layer 4, and the thermal insulation layer 3 and The refractory layers 4 are sealed; the metal rod 1 passes through the thermal insulation layer 3 and extends to the refractory layer 4, and the amorphous refractory material is cast and fixed.

[0057] In this design, the refractory layer 4 is made of amorphous refractory material: the metal rod and the anti-expansion and anti-oxidation buffer material are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com