A new comprehensive cold energy utilization system for liquefied natural gas-powered container ships

A technology for liquefied natural gas and container ships, which is applied in the direction of steam engine devices, engine components, combustion engines, etc., can solve the problems of difficult implementation of the system, complex system structure, large footprint, etc., and achieve the effect of reducing huge waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

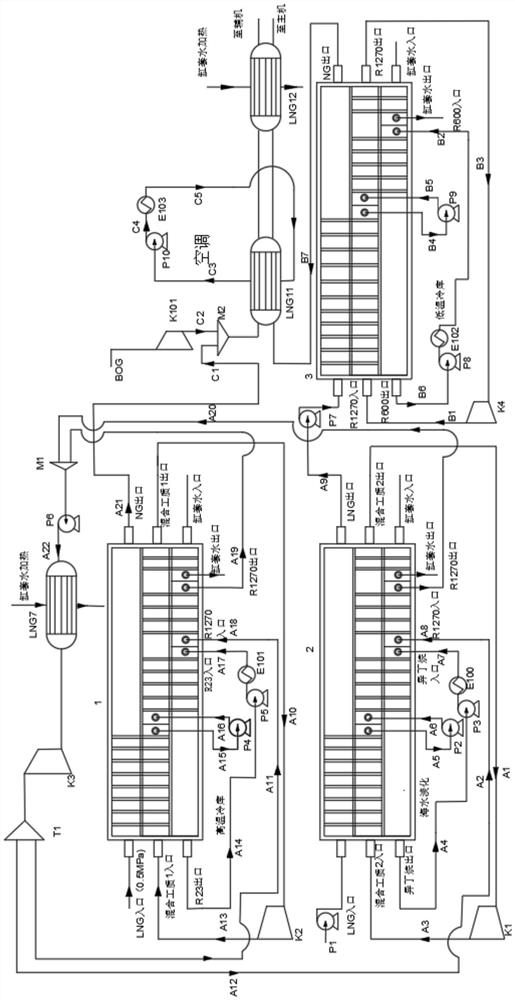

[0048] Step 1: The LNG used as fuel for the auxiliary engine is based on the integral IFV and uses a two-stage cascaded Rankine cycle to generate power

[0049] The LNG coming out of the storage tank is pressurized to 0.5MPa, the temperature is -162°C, and sent to the integral IFV1. The first-stage Rankine cycle working fluid first absorbs part of the heat of the high-temperature cold storage system working fluid, and then absorbs the heat of the second-stage The heat of the Rankine cycle working fluid and the heat of the jacket water are vaporized, and after the work done by the expander K2, the LNG is cooled and liquefied and the LNG is gasified into NG. The second-stage Rankine cycle working fluid absorbs part of the waste heat of the main engine jacket water to generate Gasification, after the work done by the expander K3, it is cooled and liquefied by the working fluid of the first-stage Rankine cycle;

[0050] Step 2: The LNG used as fuel for the main engine is based on ...

Embodiment 2

[0065] Step 1: The LNG used as fuel for the auxiliary engine is based on the integral IFV and uses a two-stage cascaded Rankine cycle to generate power

[0066] The LNG coming out of the storage tank is pressurized to 1MPa, the temperature is -160°C, and sent to the integral IFV1. The first-stage Rankine cycle working fluid first absorbs part of the heat of the high-temperature cold storage system working fluid, and then absorbs the heat of the second-stage Rankine cycle. The heat of the Ken cycle working fluid and the heat of the jacket water are vaporized, and after the work done by the expander K2, the LNG is cooled and liquefied and the LNG is gasified into NG. The second-stage Rankine cycle refrigerant absorbs part of the waste heat of the cylinder jacket water of the main engine to generate gas. liquefied, after the work done by the expander K3, it is cooled and liquefied by the first-stage Rankine cycle working fluid;

[0067] Step 2: The LNG used as fuel for the main e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com