Power, cooling/heating energy supply system and method for cascade recovery of vehicle engine waste heat

A technology of engine waste heat and cascade recovery, which is applied in the direction of engine components, combustion engines, machines/engines, etc., and can solve the problem of low energy supply and demand balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

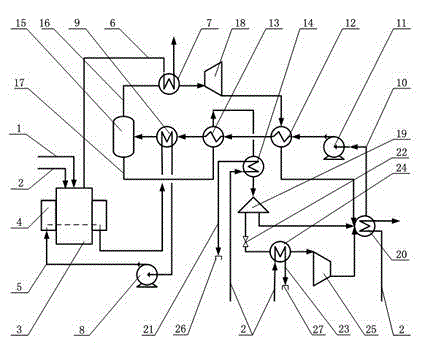

[0028] figure 1 It is the power and cold / heat energy supply system for cascade recovery of vehicle engine waste heat proposed by the present invention, refer to below figure 1 Describe the working process of the energy supply system.

[0029] First, fuel 1 and air 2 enter the cylinder of engine 3 and burn to release heat energy, part of which is converted into mechanical energy, and the remaining heat energy is taken away by engine smoke 6 and coolant 5 arranged in cylinder liner 4 around the engine. The flue gas 6 passes through the first heat exchanger 7 to heat the multi-component steam 16, after which the temperature decreases, and then it is discharged into the atmosphere. The coolant 5 at the outlet of the cylinder liner 4 enters the first heat exchanger 7 to heat the zeotropic working medium 10 , and then enters the cylinder liner 4 through the first circulation pump 8 to circulate and cool the engine 3 .

[0030] The non-azeotropic working medium 10 is pressurized by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com