A method of using a pyrolysis device

A technology of pyrolysis and pyrolysis furnace, which is applied in the direction of direct heating dry distillation, biofuel, special form of dry distillation, etc. It can solve the problems of large area, large dust content of pyrolysis gas, and increased production cost, so as to reduce dust The content of particles, efficient separation and discharge, and the effect of facilitating separation and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

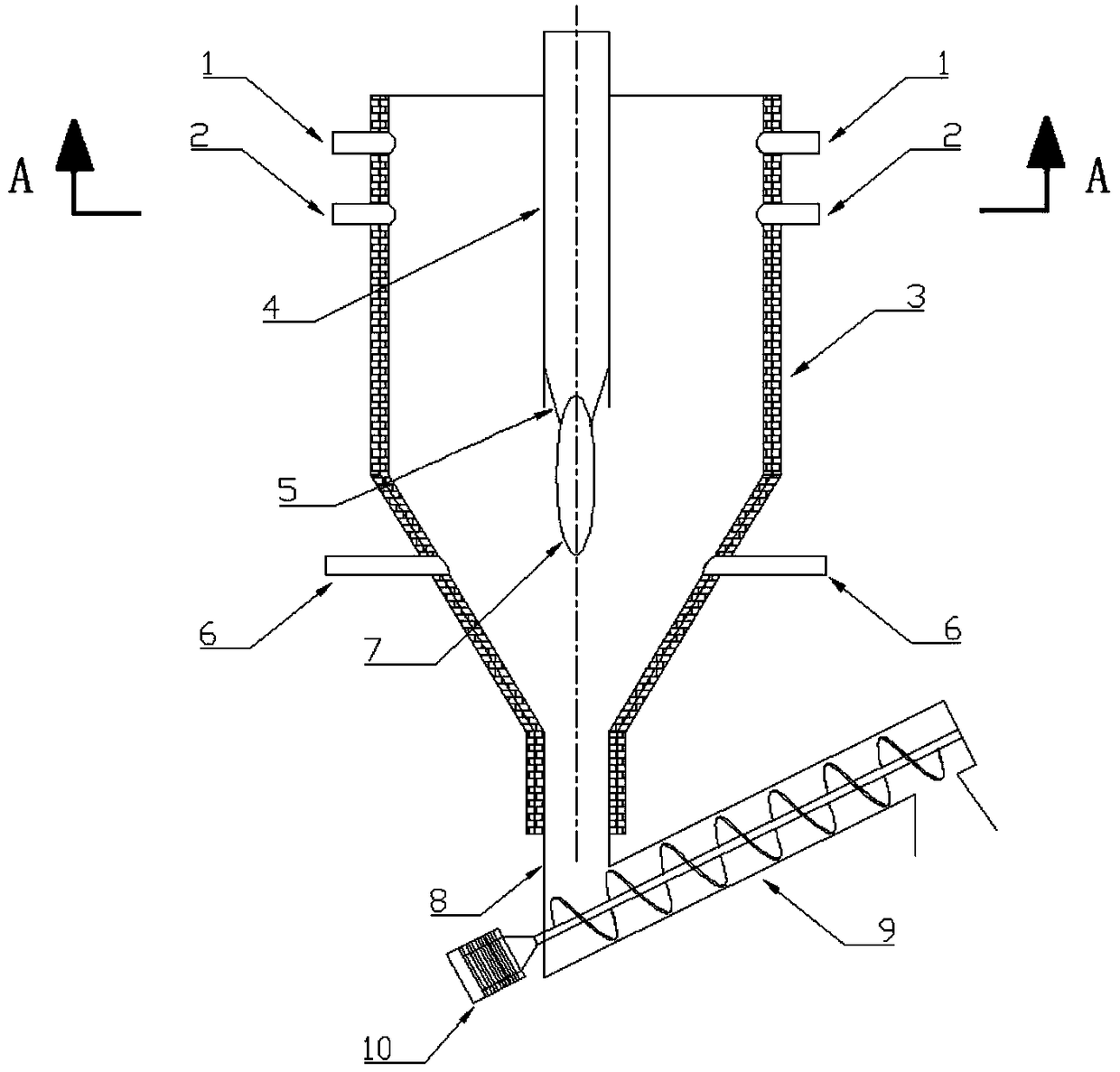

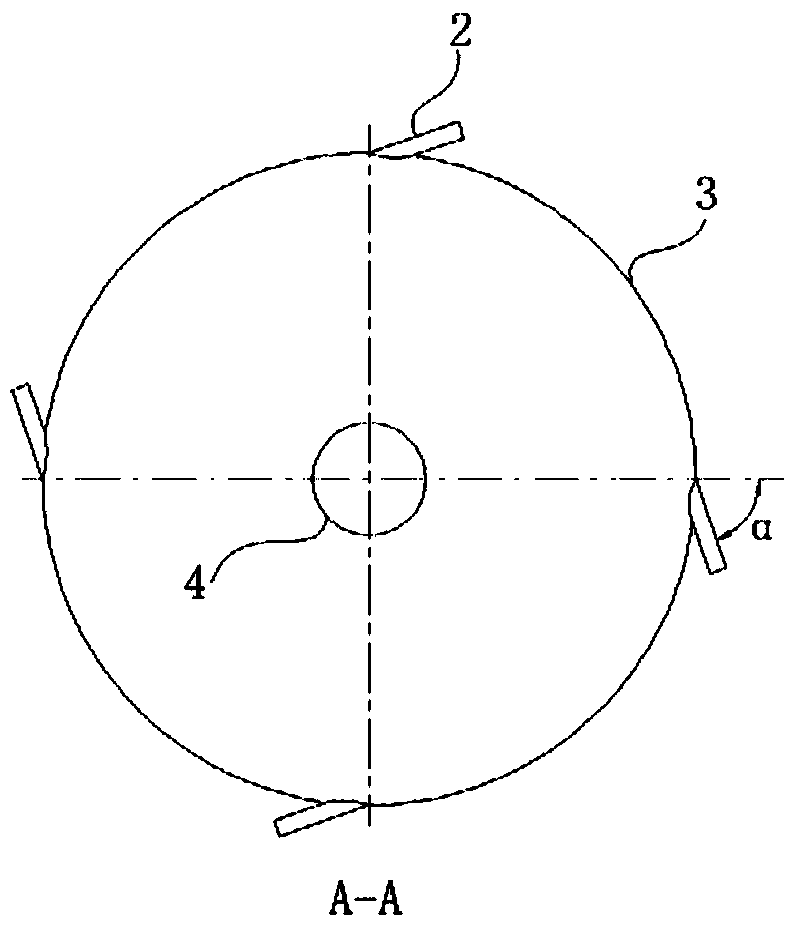

[0068] reference Figure 1~2 , The pyrolysis device of this embodiment includes: a pyrolysis furnace 3, the pyrolysis furnace 3 includes an upper straight tube section, a tapered section and a lower straight tube section connected in sequence from top to bottom. The top side of the upper straight tube section is provided with at least Two primary air inlets 2 (specifically, four primary air inlets 2 are provided in this embodiment), and the primary air inlets 2 are not tangent to the top side of the upper straight tube section; the central tube 4, the central tube 4 extends from top to bottom Into the upper straight cylinder section, and the central axis of the central cylinder 4 coincides with the central axis of the upper straight cylinder section.

[0069] In this embodiment, the top side of the upper straight barrel section is provided with at least two primary air inlets 2 along the circumferential direction, and the primary air inlet 2 is not tangent to the top side of the ...

Embodiment 2

[0077] reference image 3 The structure of the pyrolysis device of this embodiment is basically the same as that of embodiment 1, and the difference lies in:

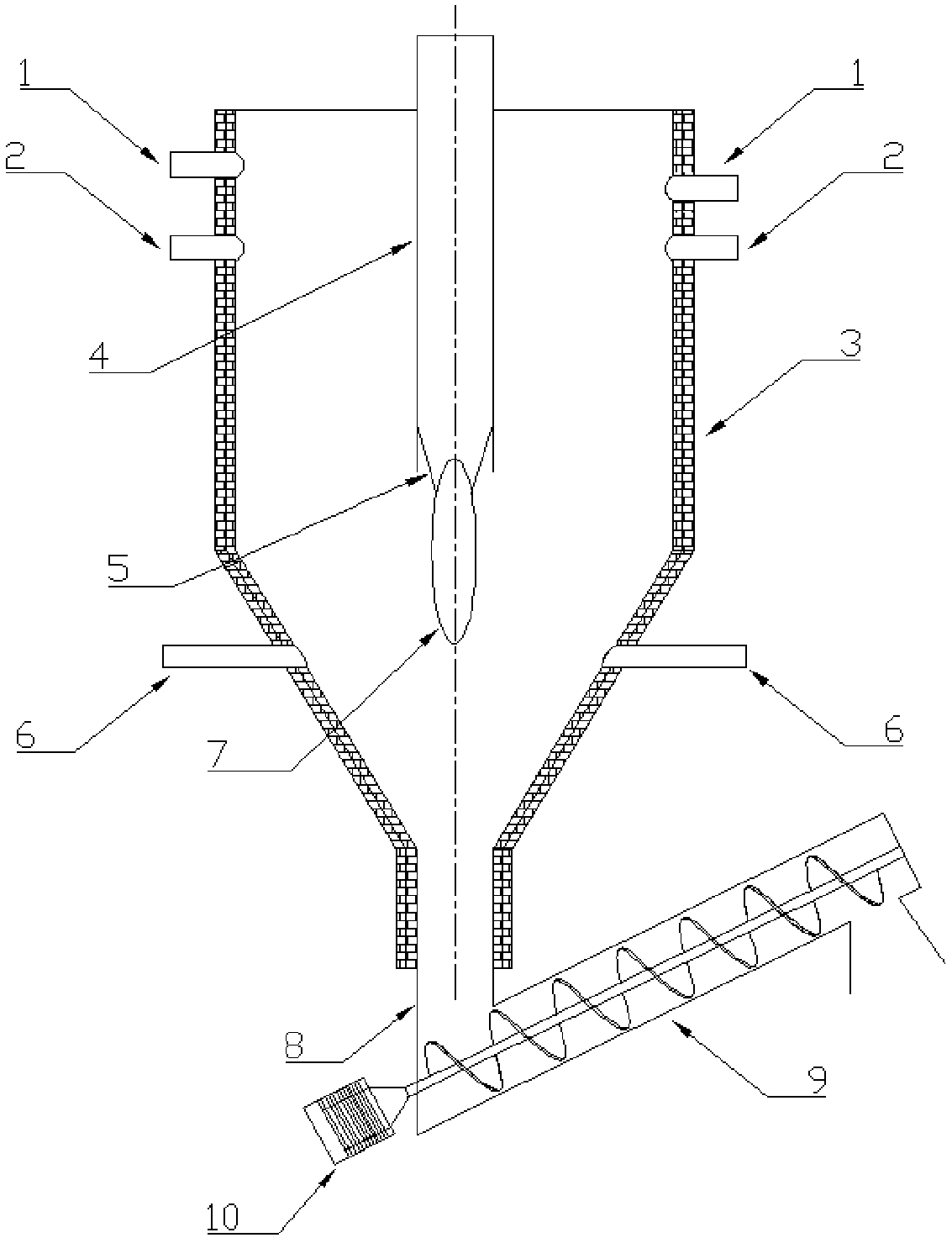

[0078] The pyrolysis device of this embodiment further includes: a feed port 1, at least two feed ports 1 (specifically, four feed ports 1 in this embodiment) are sequentially arranged on the side of the upper straight section from top to bottom; The sieving mechanism classifies the pyrolysis raw materials into different batches according to the particle size, and the pyrolysis raw materials of different batches are respectively sent to the feed inlet 1 of different heights.

[0079] In this embodiment, the sieving mechanism classifies the pyrolysis raw materials into different batches according to their particle size. The pyrolysis raw materials of different batches are sent to the feed inlet 1 of different heights, and at least two feed inlets 1 are from the top. The lower one is arranged on the side of the upper straight ...

Embodiment 3

[0081] The structure of the pyrolysis device of this embodiment is basically the same as that of embodiment 1, and the difference lies in:

[0082] The pyrolysis device of this embodiment further includes an ellipsoid 7 located below the central cylinder 4 and the upper end of the ellipsoid 7 extends into the interior of the central cylinder 4.

[0083] In this embodiment, the ellipsoid 7 is located below the central cylinder 4, and the upper end of the ellipsoid 7 extends into the interior of the central cylinder 4. The pyrolysis gas after pyrolysis contains a large number of dust particles, because the upper end of the ellipsoid 7 extends Therefore, when the pyrolysis gas containing dust particles enters the interior of the central cylinder 4 from the inlet below the central cylinder 4, the circulation area decreases abruptly, and the flow velocity of the pyrolysis gas increases, but the pyrolysis gas Due to the relatively high density of dust particles, the speed cannot be incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com