Gas burner capable of enhancing ultraviolet light signal strength

A signal strength, gas burner technology, applied in the burner, combustion method, combustion type and other directions, can solve the problems of shortening the distance between the ultraviolet flame detection probe and the flame, unstable operation of the ultraviolet flame detector, etc., to solve the problem of unstable work. , the effect of shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

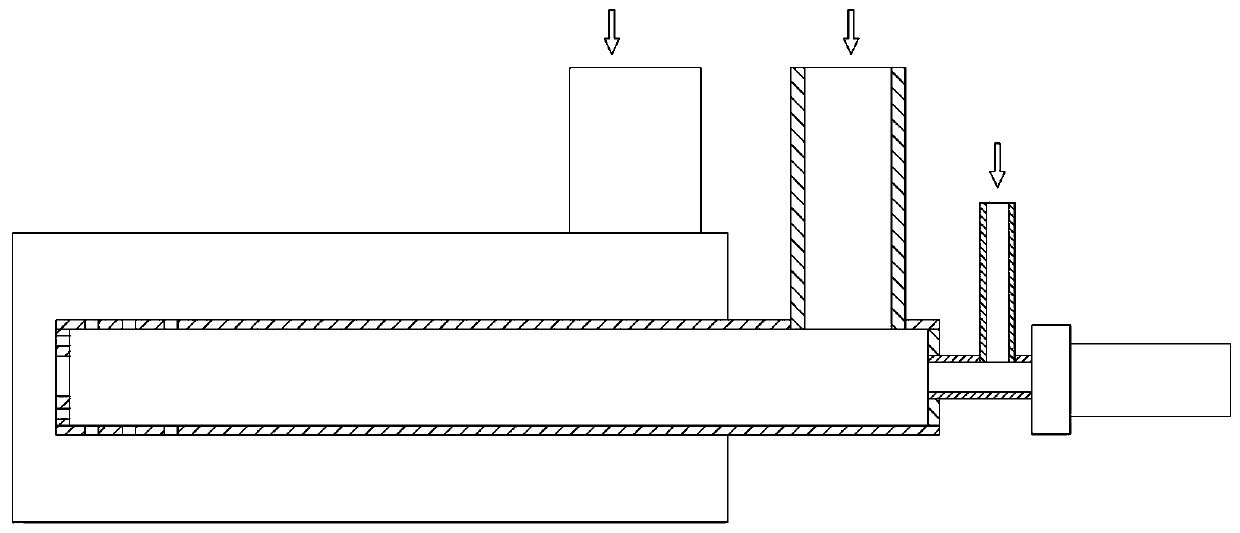

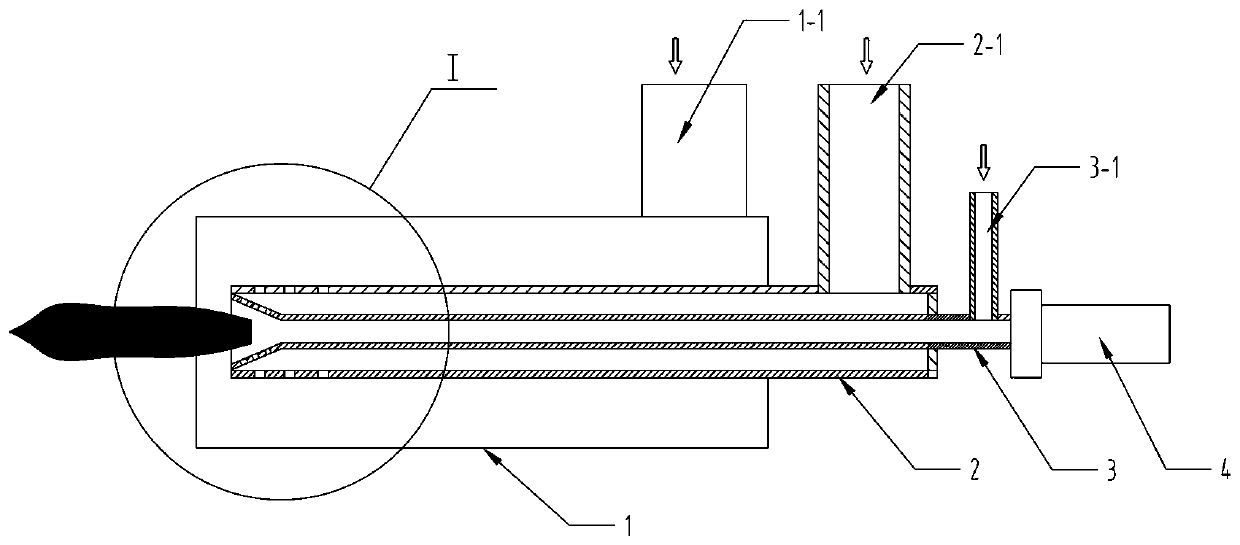

[0021] Embodiment 1, the present invention includes a burner housing 1, a gas channel 2, an ultraviolet flame detection cooling air channel 3 and an ultraviolet flame detection probe 4, the ultraviolet flame detection cooling air channel 3 extends into the gas channel 2, and The end of the detection cooling air channel 3 is provided with a through hole that communicates with the gas channel 2, and the ultraviolet flame detection cooling air is guided to the end of the ultraviolet flame detection cooling air channel 3 and mixed with gas to form a bright flame, shortening the distance between the ultraviolet flame detection probe 4 and the gas. distance between flames. refer to Figure 1 to Figure 5 .

Embodiment 2

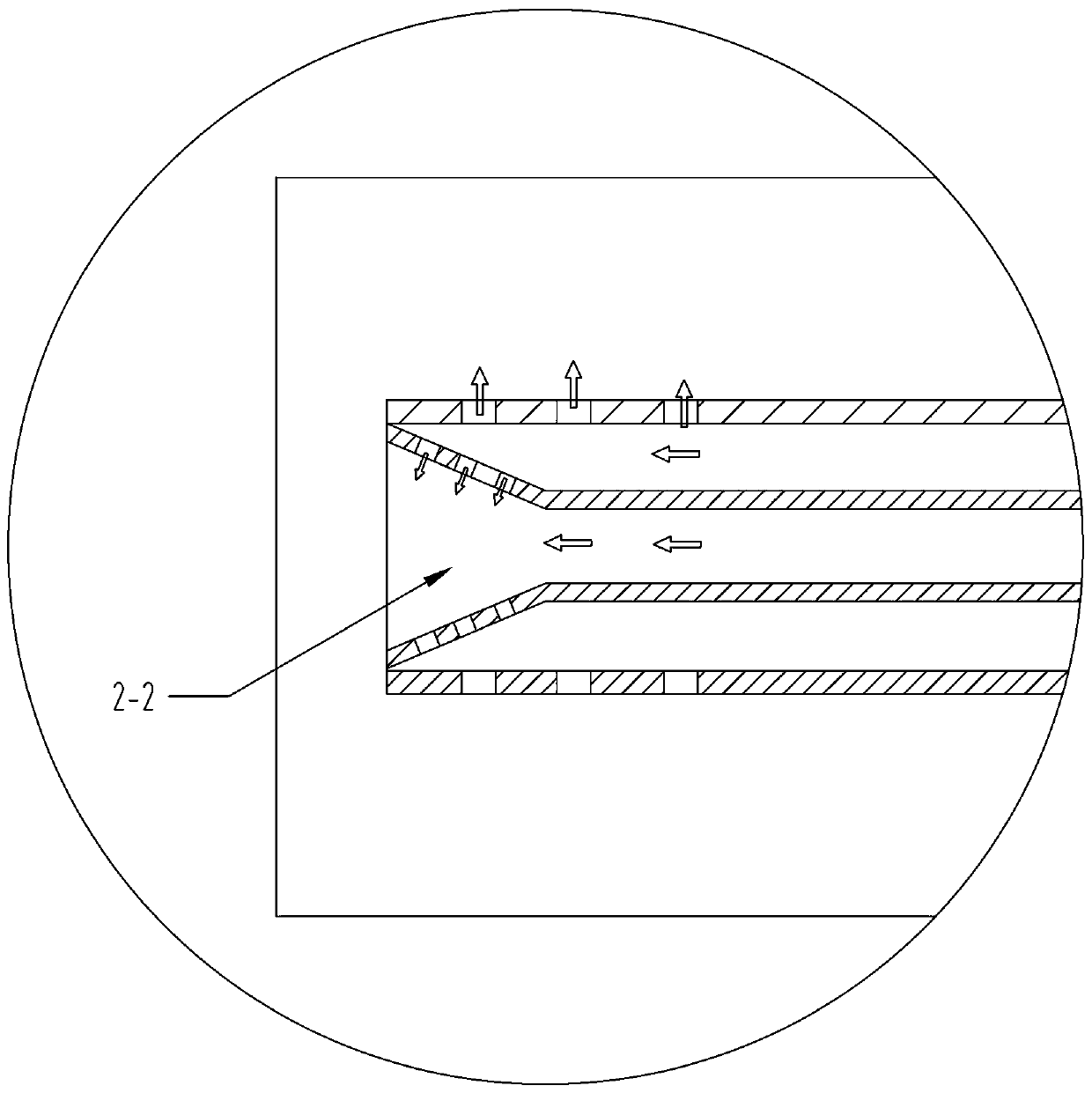

[0022] Embodiment 2, the burner casing 1 is provided with a gas passage 2, a primary air passage is formed in the burner casing 1 outside the gas passage 2, and a primary air inlet 1-1 is opened, and the gas passage 2 extends out of the burner The housing 1 is provided with one end of the primary air inlet 1-1, and a gas inlet 2-1 is provided on the side wall of the protruding part. The gas passage 2 is provided with an ultraviolet flame detection cooling air passage 3, and an ultraviolet flame detection cooling air passage 3. One end protrudes from the gas channel 2 to connect with the ultraviolet flame detection probe 4, and an ultraviolet flame detection cooling air inlet 3-1 is provided on the side wall of the extended part, and the other end is set as a bell mouth 2-2, and the bell mouth The outer wall of the big end of 2-2 is fixedly connected with the inner wall of the end of the gas channel 2, and the side wall of the bell mouth 2-2 is provided with a through hole commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com