Heat conduction and heat dissipation integrated flat heat pipe

A flat plate heat pipe and flat plate technology, which is applied in the field of heat transfer, can solve the problems of weakening heat sink heat dissipation and being unsuitable for double-sided heat source cooling, and achieves the effects of compact structure, reduced return flow distance, and increased heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and technical solutions.

[0040] In order to facilitate understanding of the present invention, the present invention will be described more fully hereinafter with reference to the related drawings. It should be understood, however, that these descriptions are only intended to further illustrate the features and advantages of the present invention, rather than to limit the claims of the present invention.

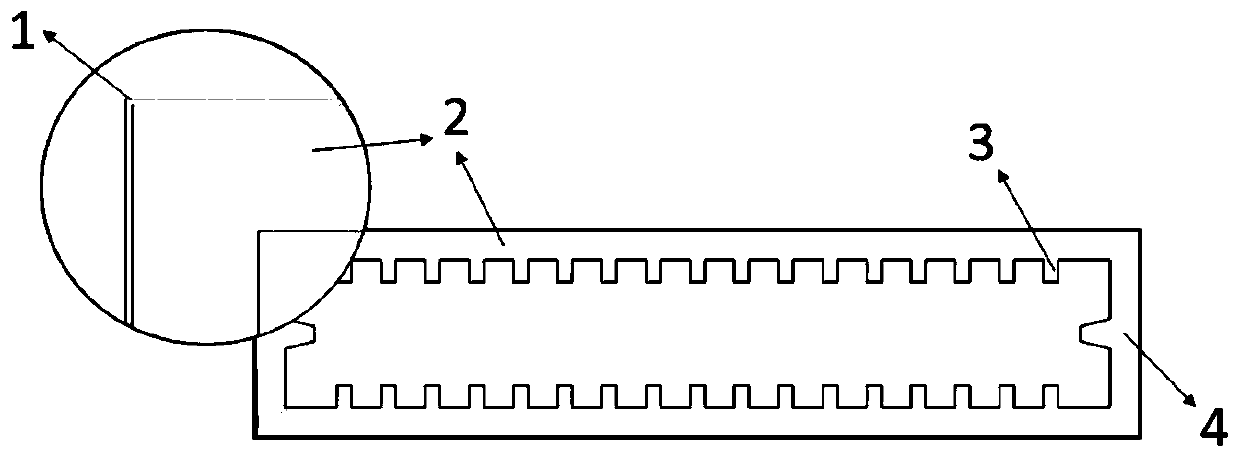

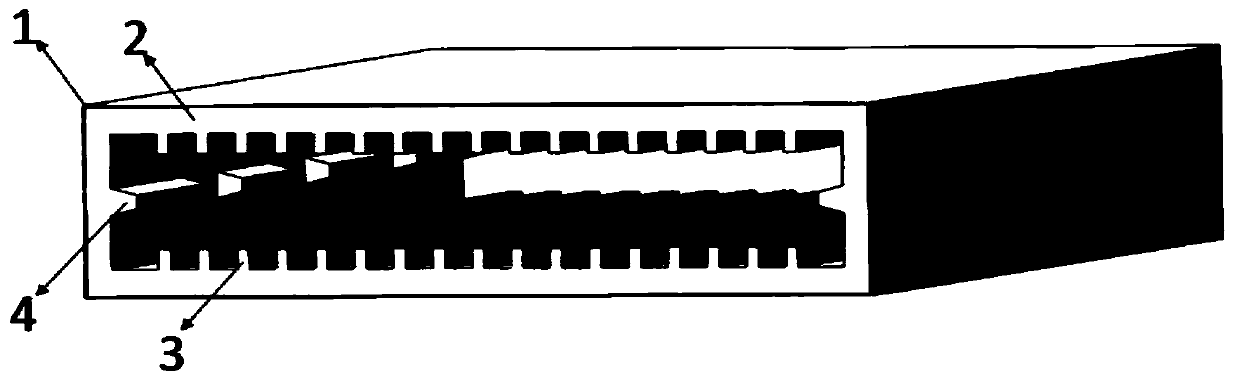

[0041] The invention discloses an integrated flat heat pipe for heat conduction and heat dissipation, comprising: a flat shell 1 , a liquid absorbing core 2 , a condenser 5 and a liquid filling pipe 13 .

[0042] The upper and lower inner surfaces of the flat housing 1 have an array of micron-sized protruding structures;

[0043] The flat shell 1 is provided with a small hole communicating with the inside thereof, and the liquid filling pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com