Quality inspection system of expiration analyzer

A quality inspection and breath analyzer technology, applied in standard gas analyzers, analyzing materials, analyzing gas mixtures, etc., can solve the problem of low detection range of breath analyzer instruments, no literature reports on stability, standard cylinder storage time and Accuracy is difficult to guarantee and other problems, to achieve the effect of simplifying the quality inspection operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

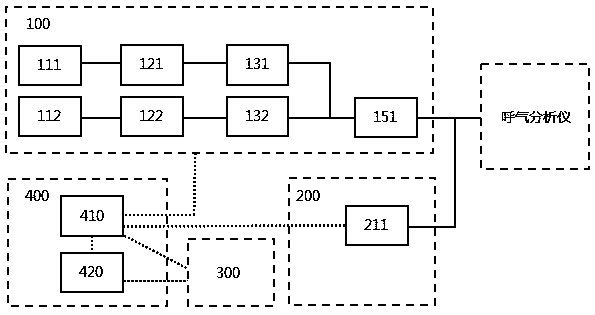

[0024] In this embodiment, the structural representation of the quality inspection system using breath analyzer figure 2 Assemble the quality inspection system of the breath analyzer, and conduct quality inspection of the breath analyzer used for respiratory detection.

[0025] The quality inspection system of the breath analyzer used in this embodiment is composed of an automatic gas distribution unit (100), a breath sampling quality inspection unit (200), a breath analysis quality inspection unit (300) and a total control unit (400); The gas distribution unit (100) includes two gas distribution pipelines and flow sensors (151), and each gas distribution pipeline is provided with gas cylinders (111, 112), pressure reducing valves (121, 122) and electromagnetic proportional valves (131 , 132), are connected in parallel to the flow sensor (151); the breath sampling quality inspection unit (200) includes a pressure sensor (210), and the pressure sensor (210) is connected to the...

specific Embodiment 2

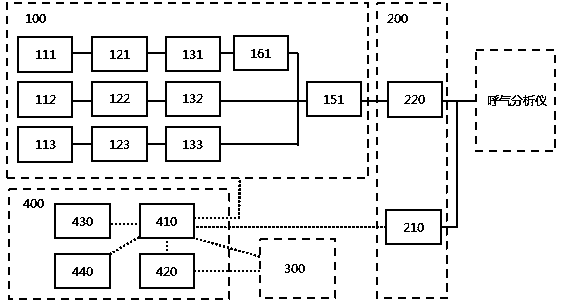

[0041] In this embodiment, the structural representation of the quality inspection system using breath analyzer figure 2 Assemble the quality inspection system of the breath analyzer to monitor the quality of the breath analyzer used for respiratory detection.

[0042] The quality inspection system of the breath analyzer used in this embodiment is composed of an automatic gas distribution unit (100), a breath sampling quality inspection unit (200), a breath analysis quality inspection unit (300) and a total control unit (400); The gas distribution unit (100) includes three gas distribution pipelines and a flow sensor (151), and each gas distribution pipeline is connected in series with gas cylinders (111, 112, 113), pressure reducing valves (121, 122, 123) and solenoid valves. The proportional valves (131, 132, 133) are all connected in parallel to the flow sensor (151). The breath sampling quality inspection unit (200) includes a pressure sensor (210), and the pressure sens...

specific Embodiment 3

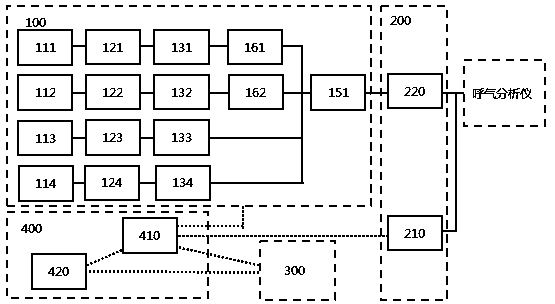

[0054] In this embodiment, the structural representation of the quality inspection system using breath analyzer Figure 4 Assemble the quality inspection system of the breath analyzer to monitor the quality of the breath analyzer used for digestive tract testing.

[0055] The quality inspection system of the breath analyzer used in this embodiment is composed of an automatic gas distribution unit (100), a breath sampling quality inspection unit (200), a breath analysis quality inspection unit (300) and a total control unit (400); The gas distribution unit (100) includes three gas distribution pipelines and a flow sensor (151), and each gas distribution pipeline is provided with gas cylinders (111, 112, 113, 114) and pressure reducing valves (121, 122, 123, 124) and electromagnetic proportional valves (131, 132, 133, 134), are all connected in parallel to the flow sensor (151). The heating and humidifying modules (161, 162) are arranged on the two gas distribution pipelines, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com