Reaction device with heat exchanger and use thereof

A technology of reaction device and heat exchanger, which is applied in the direction of moving pipe heat exchanger, pyrolysis reaction, heat exchange equipment, etc., can solve the problems affecting the safety of the system, complexity, pressure increase, etc., so as to save investment costs and Energy cost, effect of efficient energy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

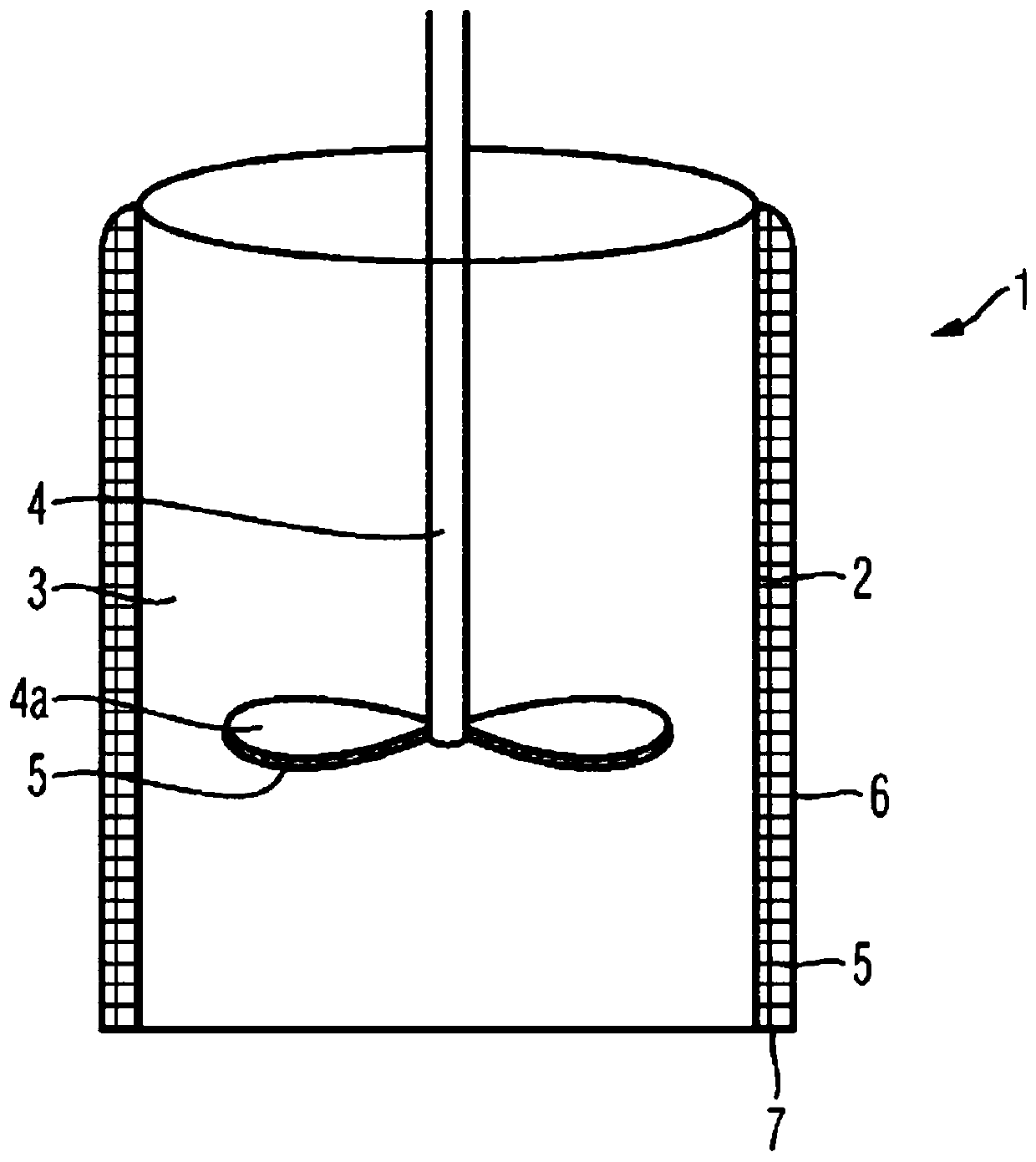

[0060] figure 1 A reaction device 1 according to the invention is shown. The device has a first wall 2 delimiting an interior space 3 housing a stirring mechanism 4 . Furthermore, the reaction device according to the invention has a second wall 6 which delimits an intermediate space 7 between the first wall 2 and the second wall 6 . In this intermediate space 7 there is a heat exchanger 5 . The stirring mechanism 4 has hollow screw blades 4 a which accommodate the heat exchanger 5 in the same way as the heat exchanger 5 is accommodated in the intermediate space 7 between the first wall 2 and the second wall 6 .

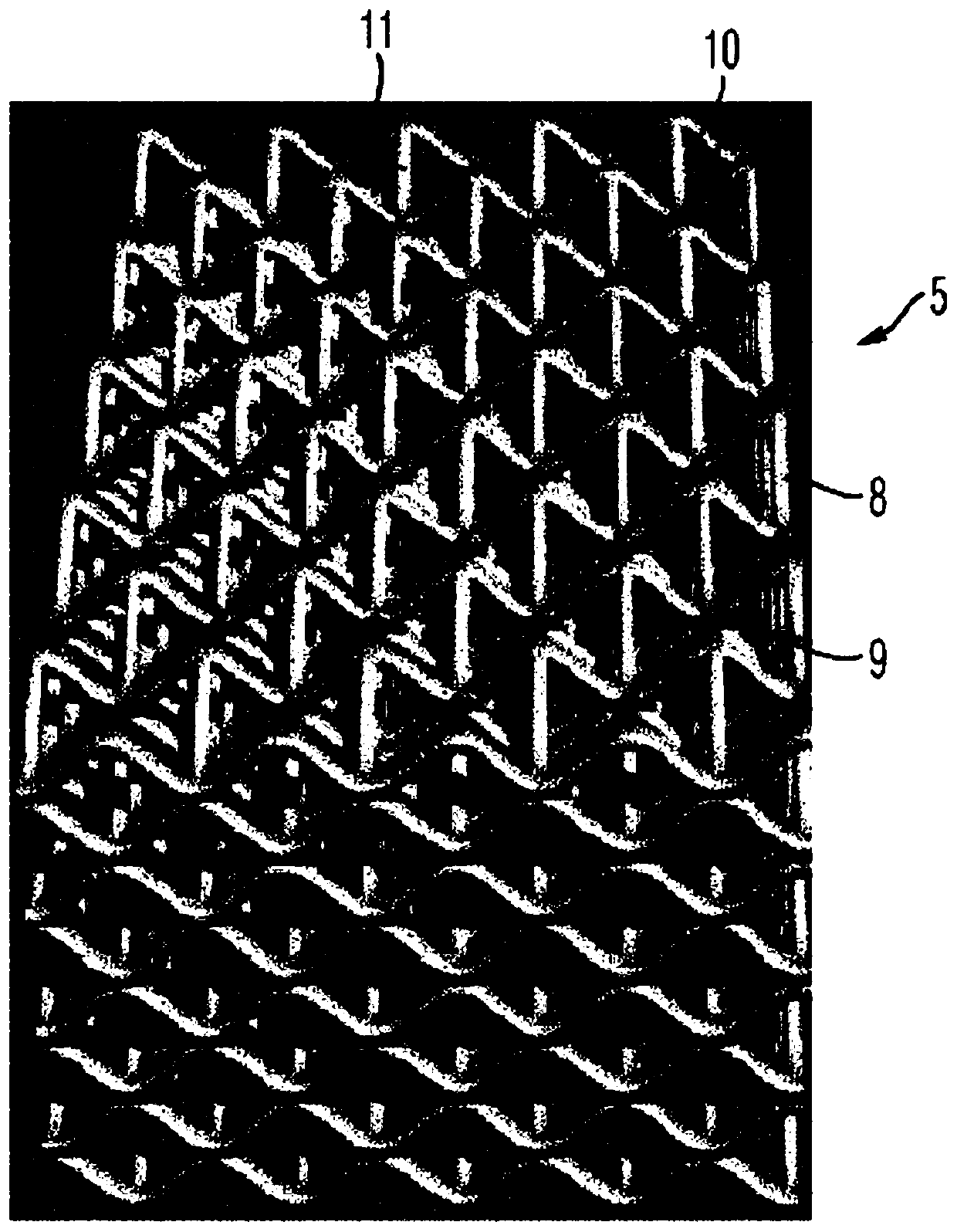

[0061] figure 2A heat exchanger 5 is shown. Grid construction involves stacked, constructed grids with wires 8 that contact and are welded directly to wires 8 of adjacent grids at contact points 9, which is useful in lower temperature ranges. It is especially useful for internal heat transfer. The grid structure has meshes 10 and thus it is a screen. Furthermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com