Extruding machine capable of automatically discharging screw rod

An extruder and screw technology, which is applied in the field of extruders that can automatically discharge the screw, can solve the problems of time-consuming and labor-intensive extraction, template end face or template end face damage, molding material pollution, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

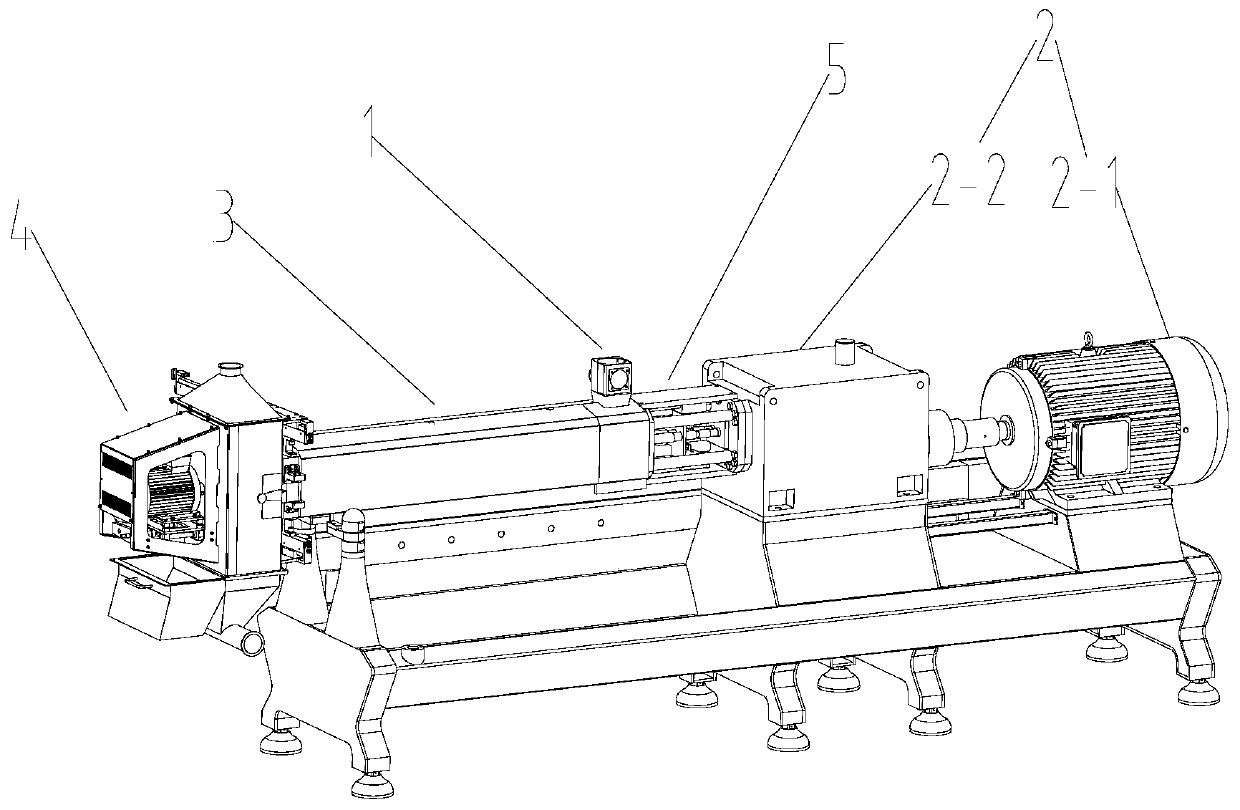

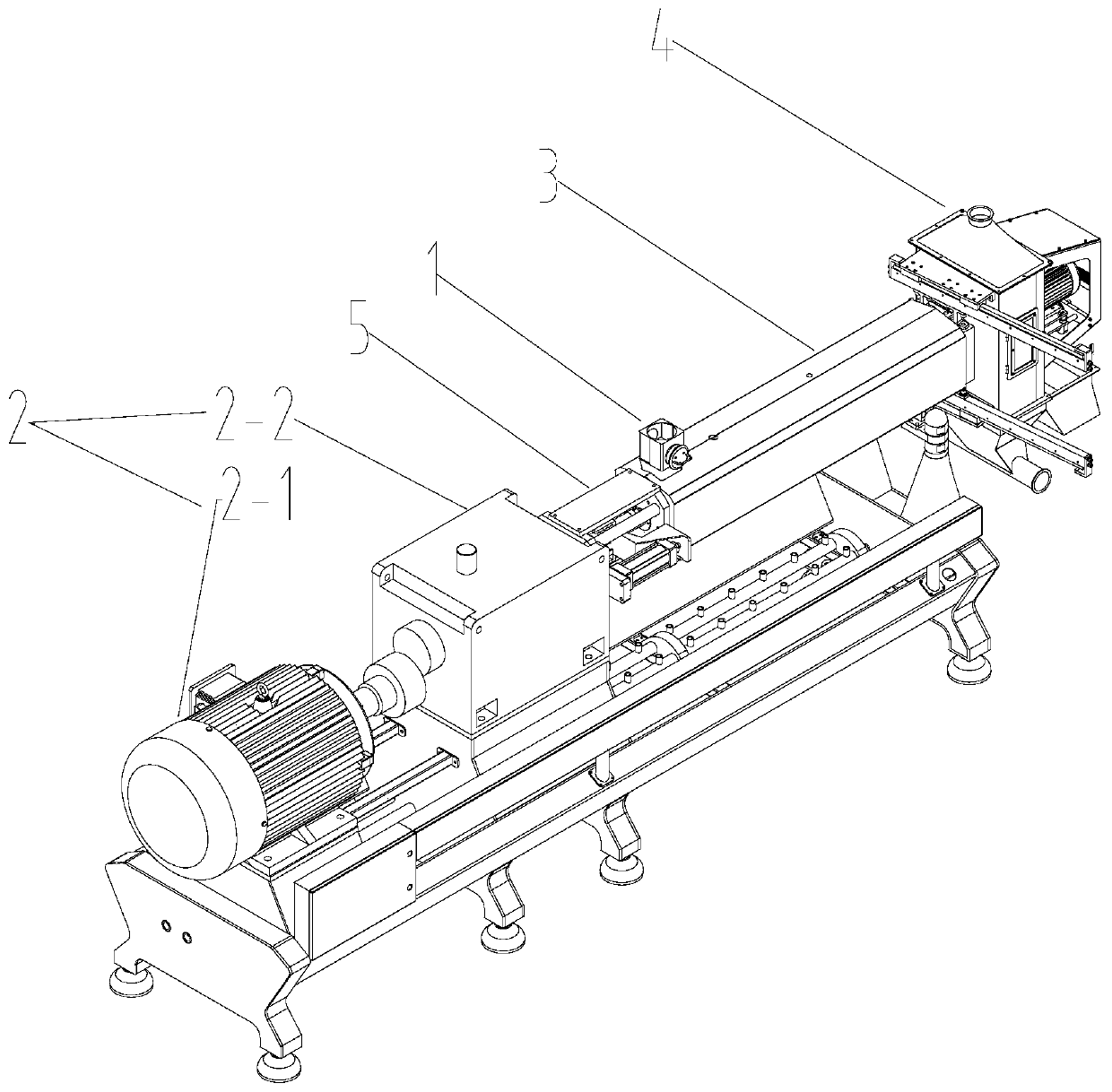

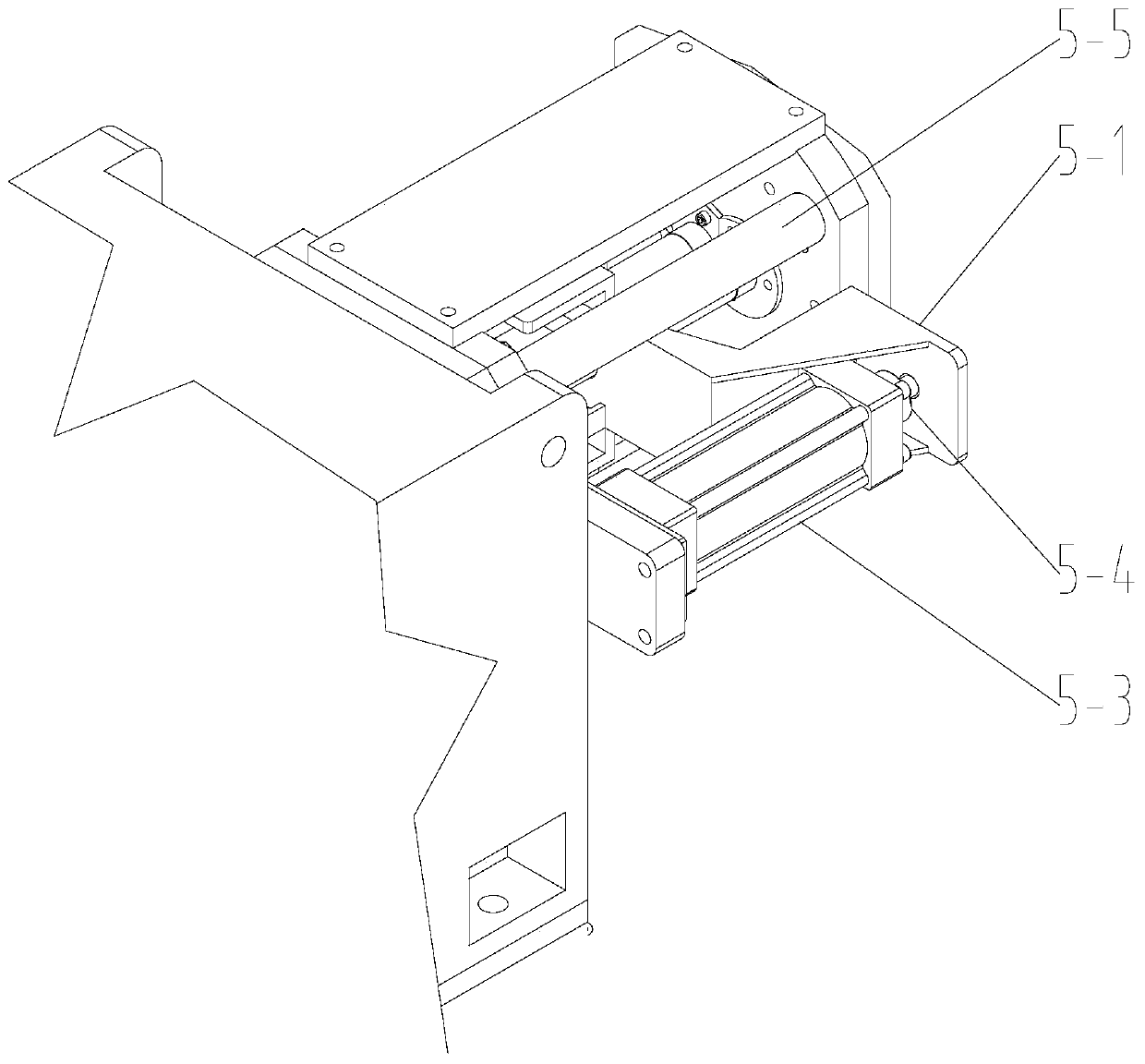

[0036] like Figure 1-4 As shown, this embodiment exemplifies an extruder that can automatically discharge the screw, including a feeding system 1, an extrusion system 3 and a discharge system 4 that are connected in sequence, and also includes a transmission system 2 that drives the extrusion system 3. The system 2 includes a motor 2-1 and a gearbox 2-2, the extrusion system 3 includes a barrel 3-2 and a screw 3-1 passing through the barrel 3-2, and the end of the screw 3-1 is connected to the gearbox 2- 2 are connected, between the gearbox 2-2 and the barrel 3-2, a screw ejection mechanism 5 is provided, and the screw ejection mechanism 5 is used to push the screw 3-1 out of the barrel 3-2.

[0037] The transmission system drives the screw to rotate, and the screws and the screw and the barrel interact together to extrude the material. After the extrusion is completed, the discharge system is generally unscrewed, and then the screw is pulled out from the barrel. The existing...

Embodiment 2

[0047] like Figure 5 As shown, the technical features of this embodiment that are the same as those of this embodiment will not be described in detail, and the technical features of this embodiment that are different from those of Embodiment 1 are:

[0048] The discharge system 4 includes a machine head 4-1;

[0049] Both sides of the end of machine barrel 3-2 are provided with the second guide rail 2-3 that extends to the outside, and the second guide rail 2-3 is arranged obliquely, and the machine head 4-1 is provided with and cooperates with the second guide rail 2-3. Slider 4-3.

[0050] After the extruder stops working, the screw rod of the extruder needs to be cleaned, and the discharge system needs to be separated from the barrel. The head of the extruder in the prior art moves along the guide rail to a direction away from the barrel. Then pull out the screw from the barrel, and return the machine head after cleaning the screw. The setting direction of the guide rai...

Embodiment 3

[0053] like Figure 6-7 As shown, the technical features of this embodiment that are the same as those of Embodiment 1-2 will not be repeated, and the technical features of this embodiment that are different from those of Embodiment 1-2 are:

[0054] The discharge system 4 includes a head 4-1 and a hopper 4-2, the head 4-1 is provided with an outlet, and the hopper 4-2 is arranged at the outlet of the head 4-1;

[0055] The discharge system 4 also includes a waste hopper 4-4 arranged side by side with the discharge hopper 4-2.

[0056] The edges of the discharge hopper 4-2 and the waste hopper 4-4 are provided with a clamping plate 4-5, and the machine head 4-1 is provided with a clamping groove 4-6 for the sliding of the clamping plate 4-5.

[0057] Extruders in the prior art are only provided with a discharge hopper, and no matter the waste material generated at the beginning or the material that needs to be collected after extruding, all need to be collected from the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com