Welding device for industrial machinery production

A welding device and industrial machinery technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of difficulty in meeting large-scale round pipe welding, fixing round pipes of various sizes and specifications, and low work efficiency of workers. Improve fixing efficiency, reduce workload, and avoid the effect of insufficient fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

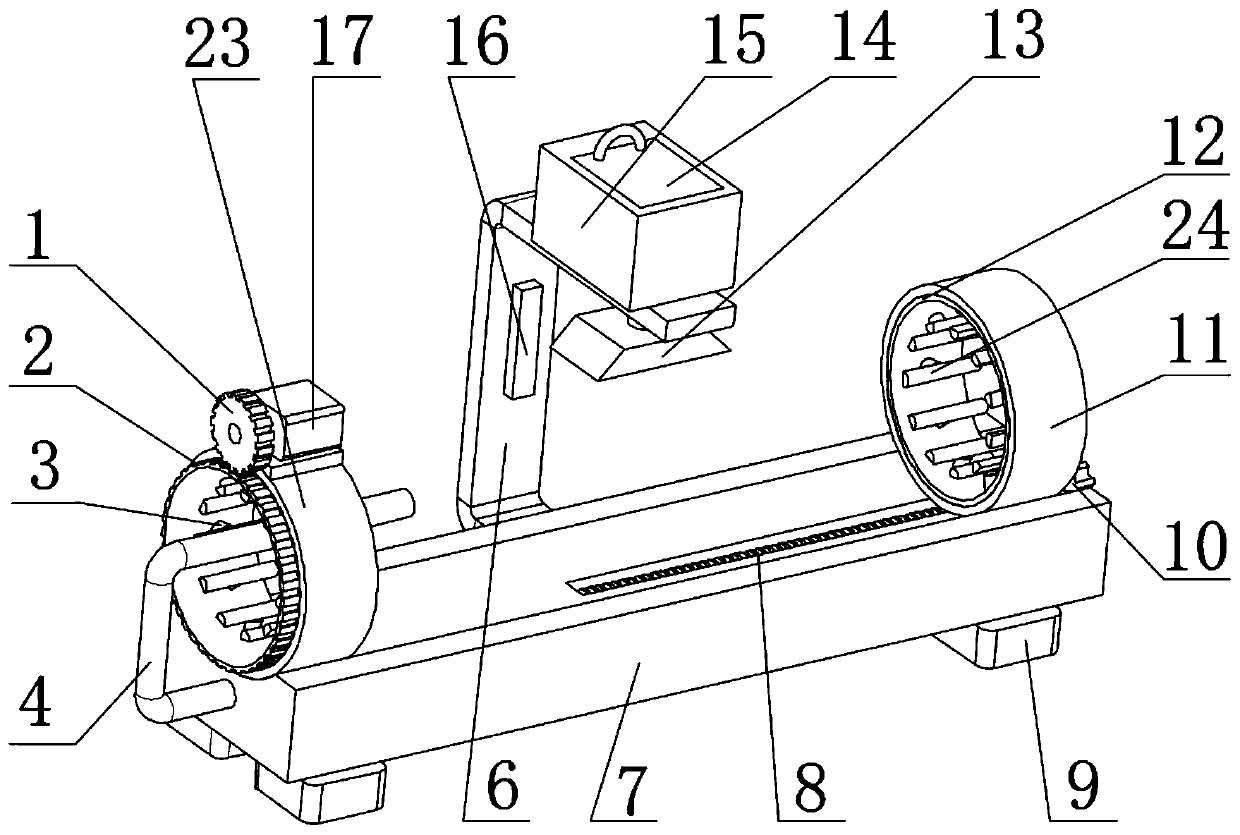

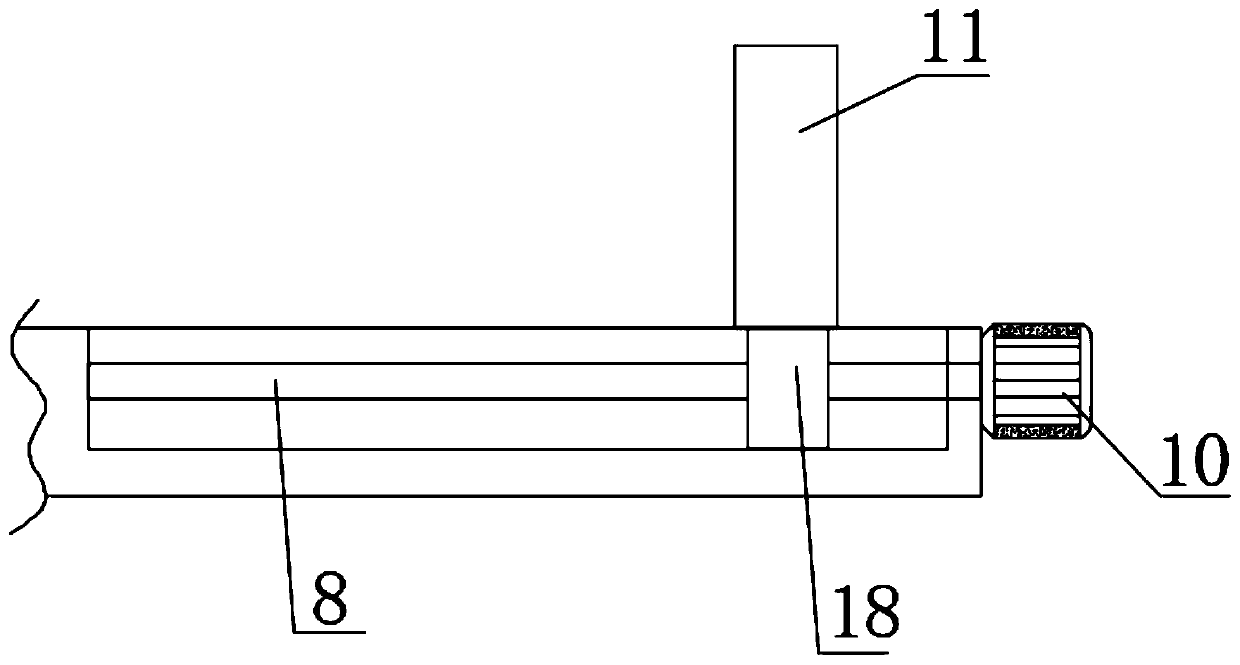

[0026] refer to Figure 1-3 , a welding device for industrial machinery production, comprising a base 7, an arc-shaped groove is provided on the top outer wall of the base 7, and a first ring 23 is installed on one side of the top outer wall of the arc-shaped groove, and the inner wall of the first ring 23 is rotatably connected with a second A fixed ring 2, and one side of the outer wall of the first fixed ring 2 is provided with tooth grooves, the outer wall of the top of the first ring 23 is equipped with a fixed plate, and the outer wall of the top of the fixed plate is equipped with a motor 17, and the outer wall of the output shaft of the motor 17 is socketed There is a gear 1, and the gear 1 meshes with the tooth grooves on the first fixed ring 2. A connecting rod 4 is installed on the outer wall of one side of the base 7, and the other end of the connecting rod 4 extends into the first fixed ring 2.

[0027] In the present invention, the four corners of the bottom oute...

Embodiment 2

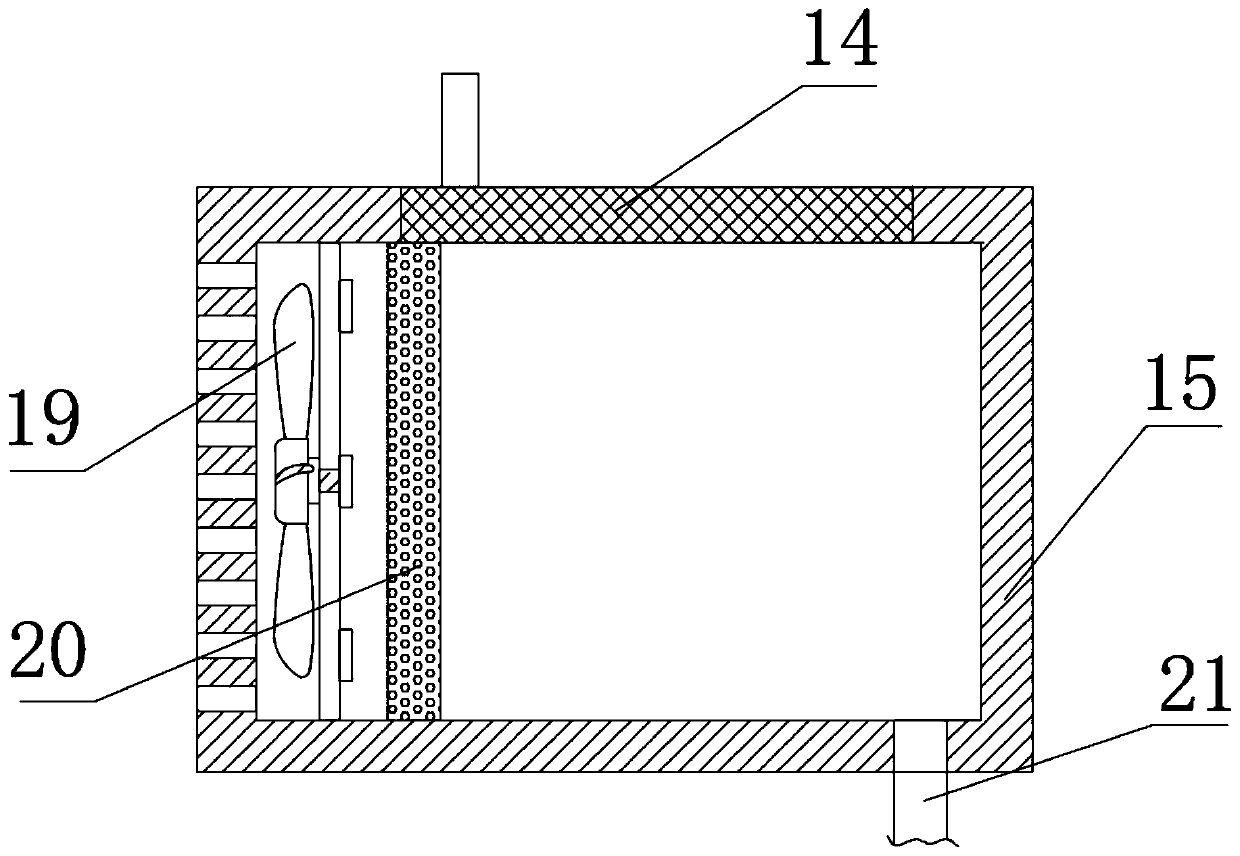

[0030] refer to Figure 1-4 , a welding device for industrial machinery production, which also includes a pressure sensor 22 installed on the top and bottom of the outer wall on one side of the second ring 11, and the same connecting ring 25 is installed on the outer wall on one side of the two pressure sensors 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com