Steady-state magnetic field coupling laser wire filling narrow groove repairing device

A technology of laser wire filling and magnetic field coupling, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of affecting performance, difficulty in application, easy residual inclusion of pores in the weld, etc., to simplify the repair process and reduce defects Quantity, simple effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

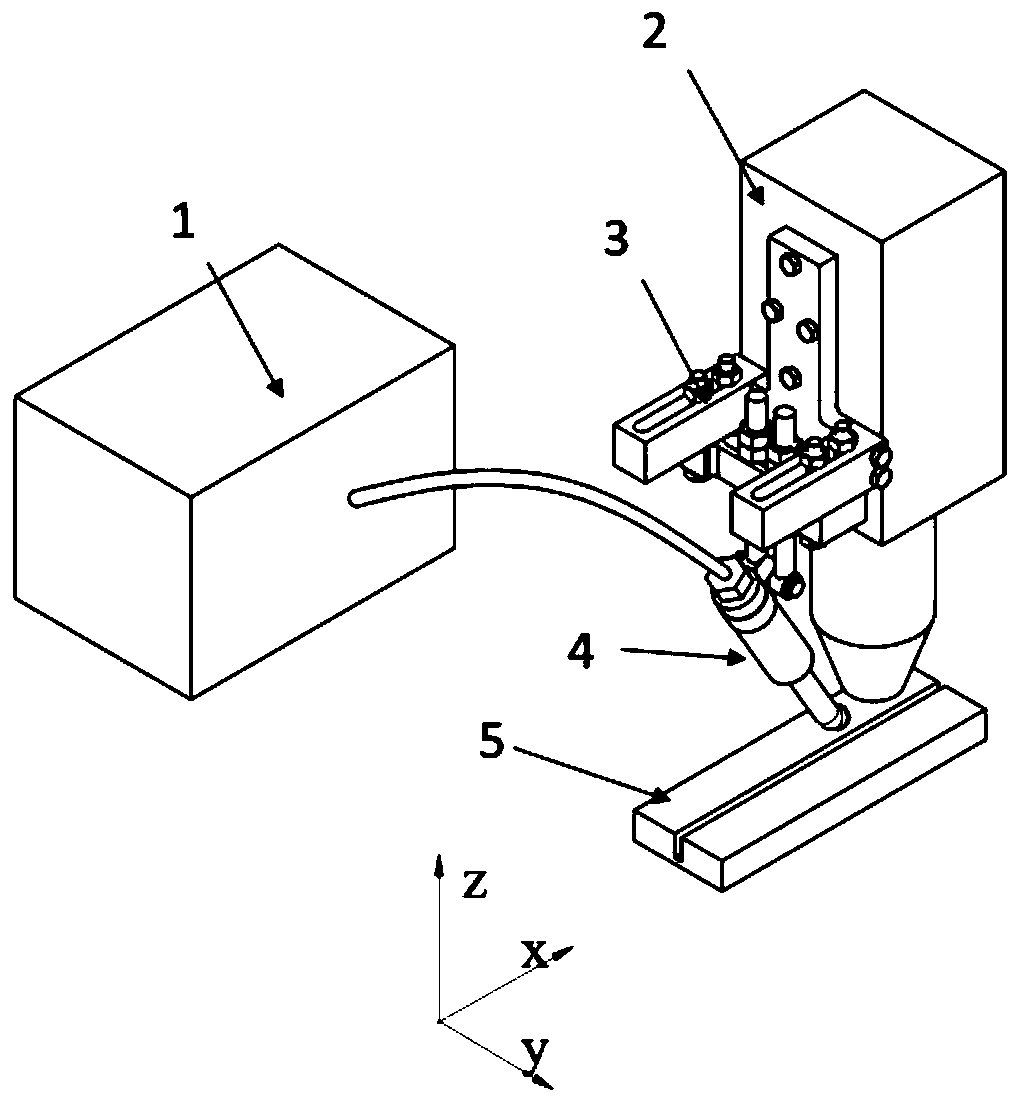

[0020] A steady-state magnetic field coupling laser wire filling narrow groove repair device includes a laser 2, a wire feeder 1, a wire feed head 4 and a clamp 3 for fixing the wire feed head and adjustable the position of the wire feed head.

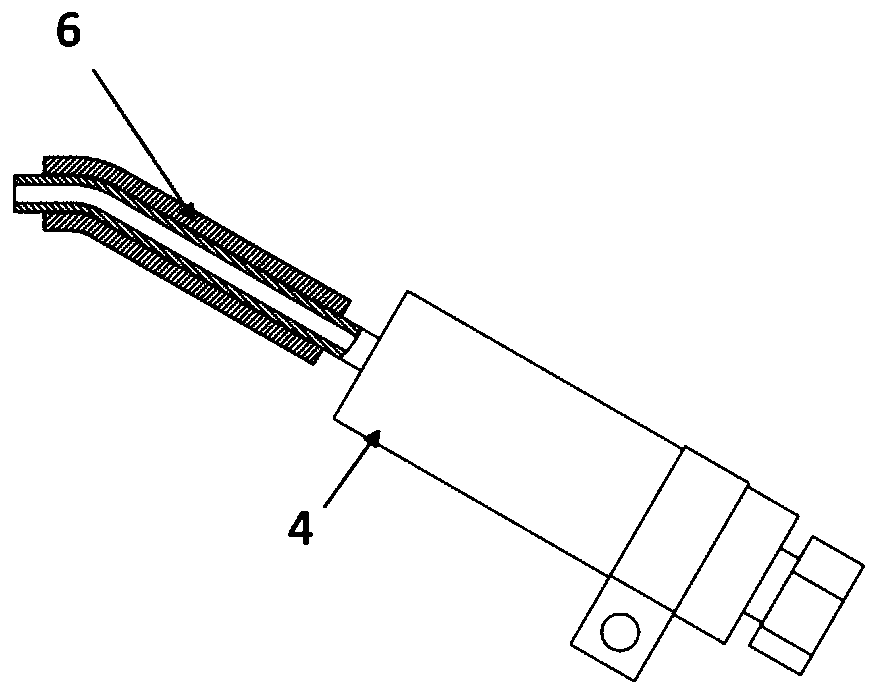

[0021] The wire feed head 4 is fixed on the laser 2 by a clamp 3, and an excitation coil 6 is provided outside the wire feed head 4, and a DC current is supplied to the excitation coil 6, so that a steady-state magnetic field is generated on the welding wire, and the steady-state magnetic field is accurately controlled by the welding wire. Sent into the molten pool area.

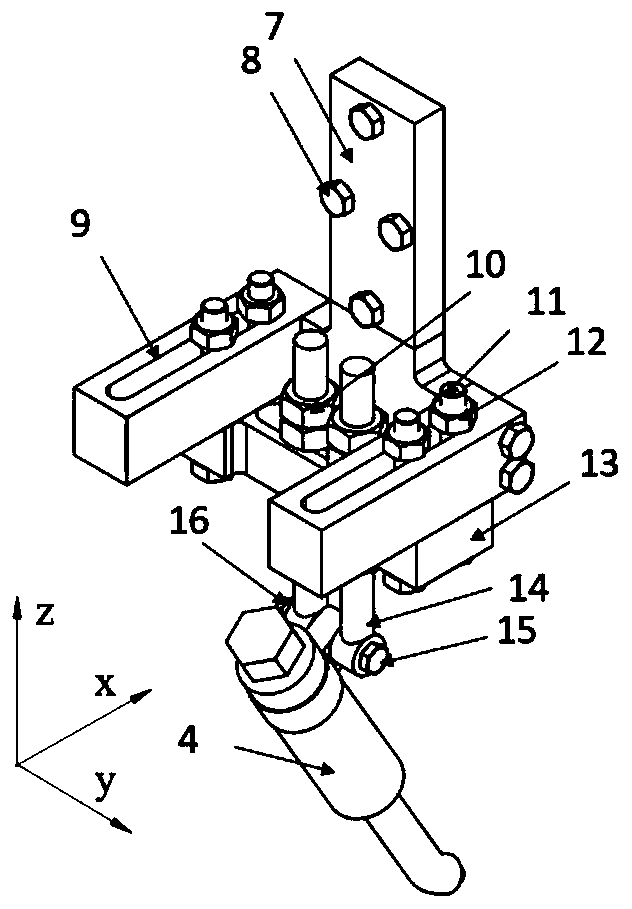

[0022] The clamp 3 includes a bottom plate 7 for fixing the clamp on the laser, a first adjustment plate 9 along the X axis direction, a second adjustment plate 13 along the Y axis direction, and a first stud 14 along the Z axis direction.

[0023] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com