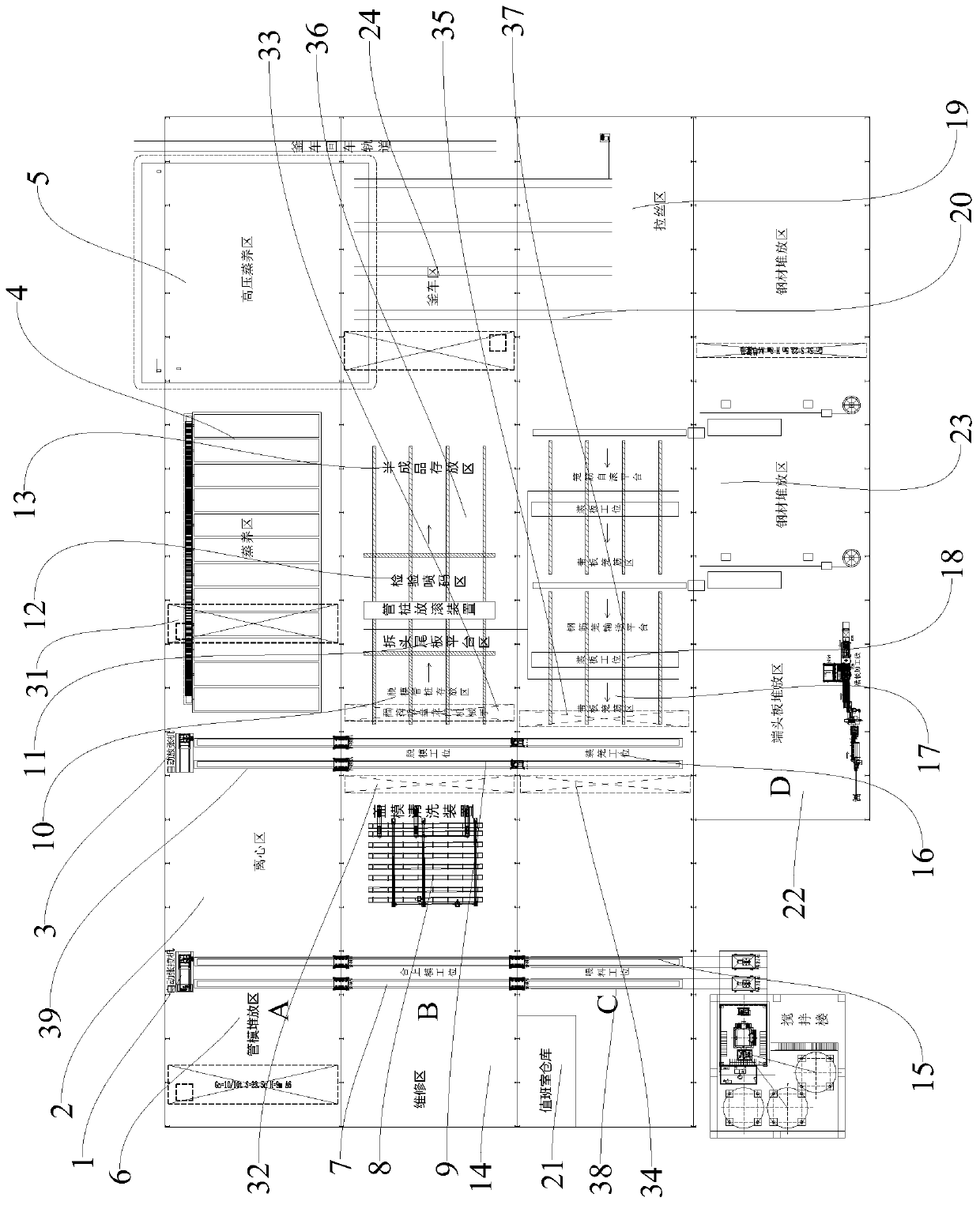

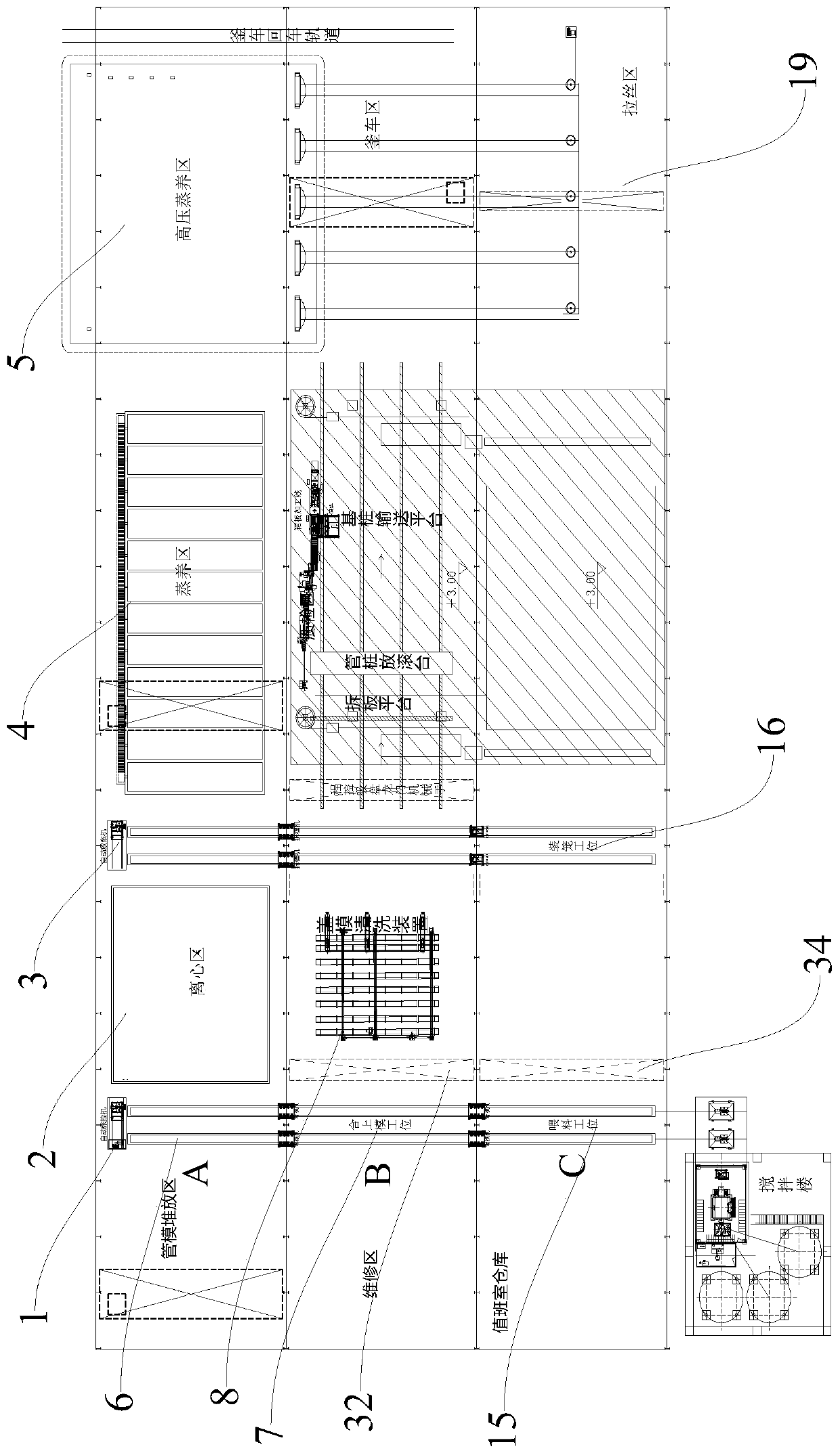

Concrete pipe pile automatic production line

An automated production line and concrete pipe pile technology, applied in reinforced molding, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of high quality requirements for workers, frequent equipment failures, and many required equipment, so as to reduce the number of workers and improve the production cycle. Short process and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] D-span workshop can be set on the same level as A-span workshop, B-span workshop and C-span workshop.

Embodiment 2

[0047] The D-span workshop can also be set above the B-span workshop, and the strip steel cage area 17, the panel loading station 18 and the C-span workshop are at different heights in the same workshop to reduce the footprint of the production line.

[0048] In addition, the D-span workshop also includes an end plate stacking area 22 , and the end plate stacking area 22 is set on the left side of the steel stacking area 23 . The end plate stacking area 22 is provided with a skirt plate processing line, which installs the skirt plate on the end plate and stacks it in the end plate stacking area 22 .

[0049] Specifically, the concrete pipe pile automatic production line also includes a conveyor, the discharge end of the conveyor is set at the board loading station 18, and the feed end of the conveyor is set at the platform area 11 of the head and tail plate for dismantling, so as to be suitable for dismantling the head and tail. The stretched boards removed from the board plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com