Clear coating compositions and methods of forming clear coating compositions

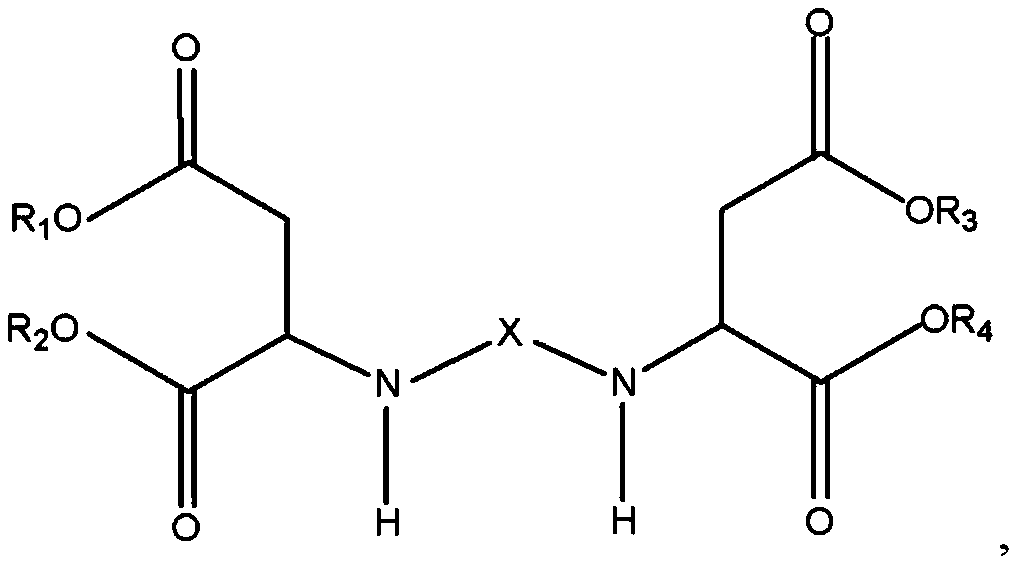

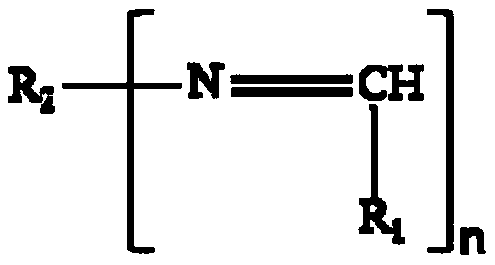

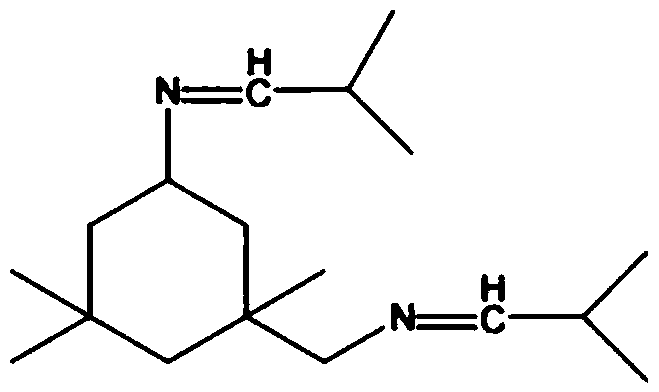

A transparent coating and composition technology, applied in the field of aspartate transparent coating composition, capable of solving problems such as damage to the transparent coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] E-coated panels were prepared with the clearcoat composition for scratch resistance testing. Specifically, Binder Part A and Activator Part B are mixed together to form a homogeneous solution. The homogeneous solution is then sprayed with a spray gun onto the e-coated panels, wherein each e-coated panel has a primer or sealant layer adjacent to the e-coat and a primer layer disposed thereon (e.g., water-based base coat). Spraying is done using a two coat process with a flash off of about 30 seconds between coats. After spraying, the clear coat composition was allowed to flash off for a period of about 3 minutes to about 5 minutes, and then the coated panels were placed in an oven operating at 110°F and baked for about 10 minutes. The coated panels were then aged for approximately two weeks to substantially fully cure the clearcoat composition before performing the scratch resistance test discussed in further detail below. A substantially fully cured clearcoat has a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com