Strong bunching inhibition environment-friendly drilling completion fluid

A technology of strong inhibition, drilling and completion, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of easy plugging of the throat, damage to downhole equipment, affecting the oil production rate in the oil production process, etc., and achieves strong degradability. performance, rapid flowback, and improved near-well permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a kind of strongly inhibited bunching environment-friendly drilling and completion fluid, which comprises 80 parts by weight of base fluid, 10 parts by weight of microemulsion nano-preparation, 1 part by weight of plugging and anti-slumping agent, and 1 part by weight of oil-soluble temporary plugging agent and 0.8 parts by weight of corrosion inhibitor; the microemulsion nano-preparation is sequentially oxidized gel breaker, biological enzyme gel breaker, acid gel breaker and capsule shell from inside to outside; oxidized gel breaker, Biological enzyme gel breaker and acid gel breaker are separated from each other by coating film;

[0028] The oxidative breaker comprises 3 parts by weight of potassium permanganate solution, 0.5 parts by weight of magnesium peroxide, 0.1 parts by weight of vegetable oil and 0.03 parts by weight of xanthan gum;

[0029] The biological enzyme gel breaker includes 3 parts by weight of 1,4-β-D-mannanase solution, 0.3 ...

Embodiment 2

[0039] The invention provides a kind of strongly inhibited bunching environment-friendly drilling and completion fluid, which comprises 90 parts by weight of base fluid, 20 parts by weight of microemulsion nano-preparation, 3 parts by weight of plugging and anti-slumping agent, and 3 parts by weight of oil-soluble temporary plugging agent and 1.2 parts by weight of corrosion inhibitor; the microemulsion nano-preparation is sequentially oxidized gel breaker, biological enzyme gel breaker, acid gel breaker and capsule shell from inside to outside; oxidized gel breaker, Biological enzyme gel breaker and acid gel breaker are separated from each other by coating film;

[0040] The oxidative breaker comprises 7 parts by weight of potassium permanganate solution, 2 parts by weight of magnesium peroxide, 0.3 parts by weight of vegetable oil and 0.08 parts by weight of xanthan gum;

[0041] The biological enzyme gel breaker includes 8 parts by weight of 1,4-β-D-mannanase solution, 0.6 ...

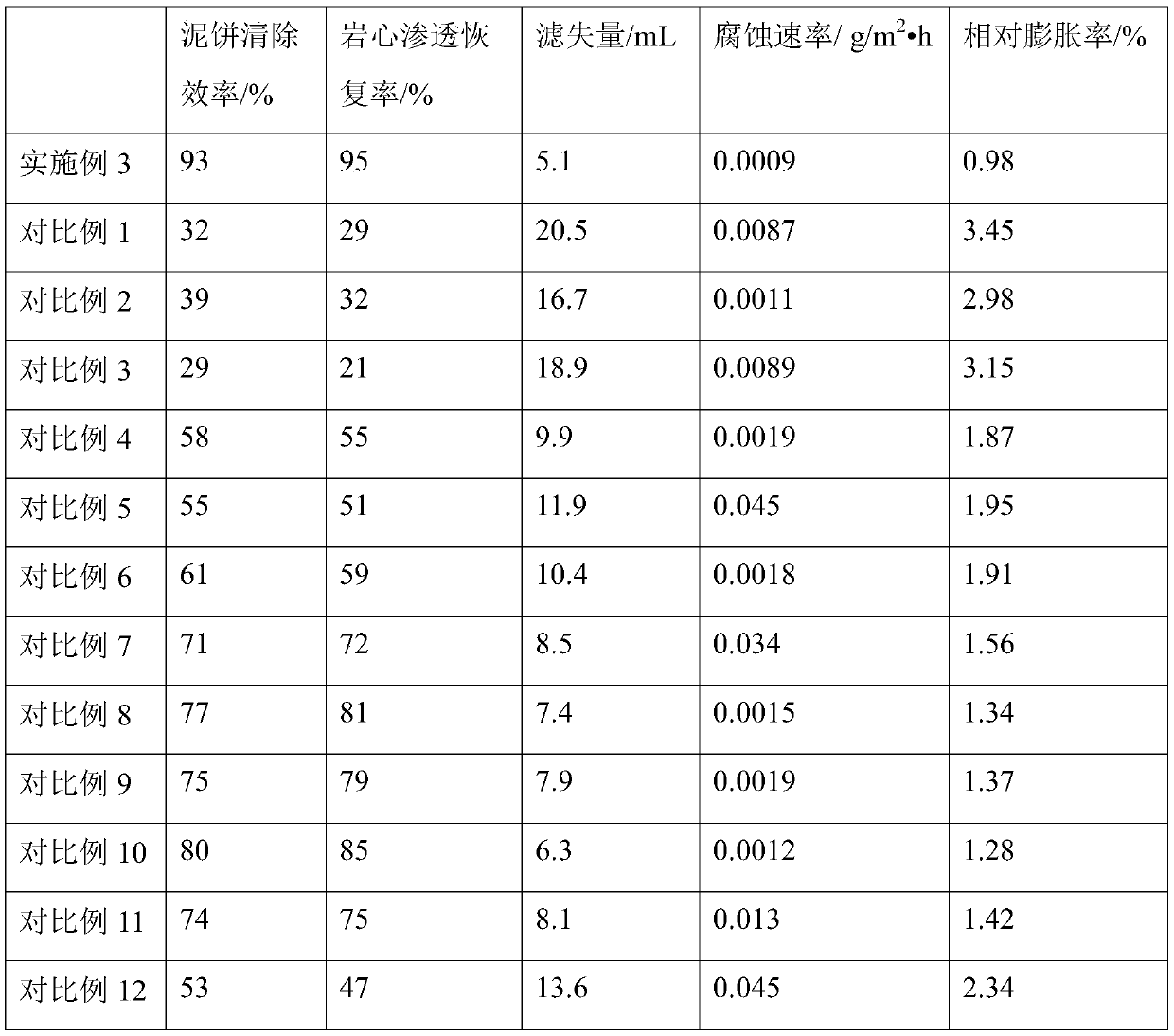

Embodiment 3

[0051] The invention provides a kind of strongly inhibited bunching environmental protection drilling and completion fluid, which comprises 85 parts by weight of base fluid, 15 parts by weight of microemulsion nano-preparation, 2 parts of plugging and anti-slumping agent, and 2 parts of oil-soluble temporary plugging agent and 1.0 parts of corrosion inhibitor; the microemulsion nano-preparation is sequentially oxidized gel breaker, biological enzyme gel breaker, acid gel breaker and capsule shell from inside to outside; oxidized gel breaker, biological enzyme breaker The glue and the acid breaker are separated from each other by the coating film;

[0052] The oxidative gel breaker comprises 5 parts by weight of potassium permanganate solution, 1.3 parts by weight of magnesium peroxide, 0.2 parts by weight of vegetable oil and 0.06 parts by weight of xanthan gum;

[0053] The biological enzyme gel breaker includes 6 parts by weight of 1,4-β-D-mannanase solution, 0.5 parts by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com