Engine oil additive composition and preparation method thereof

A technology of additives and compositions, applied in the direction of lubricating compositions, etc., which can solve the problems of high fuel consumption, high noise, and excessive exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing an engine oil additive composition. The above-mentioned engine oil additive composition is prepared. The preparation method is as follows. According to the following parts by weight, 40 parts of base oil, 5 parts of solid phase lubricant, 30 parts of diluent, and clean and dispersed Add 13 parts of the agent into the reaction kettle, heat to 50-60°C, stir at a speed of 1500-2000r / min for 20-30min, then ultrasonically mix for 10-20min, then add 3 parts of antioxidant, 5 parts of organic molybdenum compound, anti-wear 4 parts of additives are added to the reaction kettle in turn, heated to 40-50°C, stirred at a speed of 1500-2000r / min for 30-60min, then ultrasonically mixed for 20-30min, the ultrasonic frequency of ultrasonic mixing is 80-120KHZ, so as to obtain engine oil additive combination.

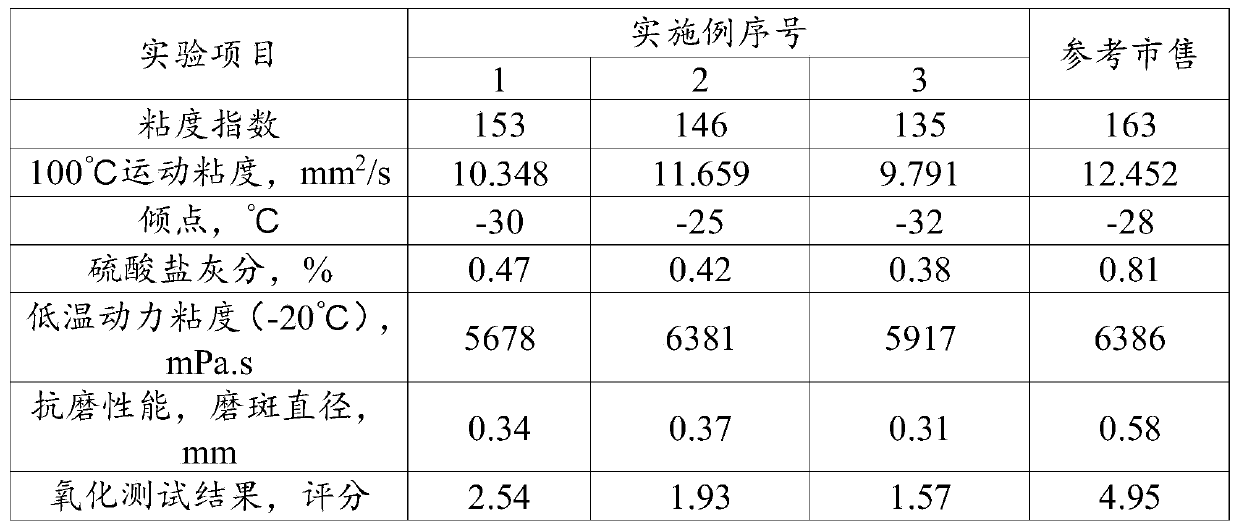

[0028] The engine oil additive composition will be obtained for performance testing, and the test results are as follows: figure 1 shown;

[0029] The en...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the engine oil additive composition is composed of the following parts by weight, wherein 38 parts of base oil, 3 parts of solid phase lubricant, 8 parts of organic molybdenum compound, 28 parts of diluent, and 15 parts of detergent and dispersant 5 parts, 5 parts of antioxidant, 3 parts of antiwear agent.

[0032] The engine oil additive composition will be obtained for performance testing, and the test results are as follows: figure 1 shown;

[0033] The engine oil additive composition has passed the driving test. The power of the invention is far more than 35% higher than that of competing products in the market. It can realize an oil change interval of 30,000 kilometers or even longer, reduce the friction coefficient by 45%, and reduce the wear by 42%. The pressure performance is increased by 2-3 times, the oil temperature rise is suppressed by more than 30°C, and the fuel is saved by about 3%. After r...

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that the engine oil additive composition is composed of the following parts by weight, wherein 43 parts of base oil, 1 part of solid phase lubricant, 2 parts of organic molybdenum compound, 40 parts of diluent, and 10 parts of detergent and dispersant 2 parts, 2 parts of antioxidant, 2 parts of antiwear agent.

[0036] The engine oil additive composition will be obtained for performance testing, and the test results are as follows: figure 1 As shown; the engine oil additive composition has passed the driving test, and the power of the present invention is far more than 35% higher than that of competing products in the market, and can realize an oil change interval of 30,000 kilometers or even longer, with a friction coefficient reduced by 53% and wear reduced by 52% %, the extreme pressure performance is increased by 2-3 times, the temperature rise of the oil is suppressed by more than 30°C, and the fuel is save...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com