Ion nitriding process for parking brake ejector rod of railway vehicle

A technology of ion nitriding and parking braking, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of air pollution in the production workshop, waste of metal copper resources, low production efficiency, etc., and achieve reduction The defect rate and dimensional deformation are uniform and the effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0031] The invention relates to an ion nitriding process for a rail vehicle parking brake ejector rod, the steps are as follows:

[0032] a. Before nitriding treatment, blunt the sharp corner of the hole on the brake ejector rod 1;

[0033] b. Put the first protective sleeve 4 on the end of the brake ejector 1 with the internal thread hole 3, and put the second protective sleeve 5 on the other end of the brake ejector 1 with the sealing groove 2;

[0034] c. Put the brake ejector rod 1 covered with the first protective cover 4 and the second protective cover 5 into the nitriding furnace;

[0035] d. In the ion nitriding heating stage, when the temperature of the brake ejector rod 1 rises to 300°C, after 3 hours of heat preservation, the temperature is raised to 540°C±10°C, and the temperature is maintained for 24 to 30 hours for ion nitriding treatment;

[0036] e. After the nitriding is completed, wait for the nitriding furnace to cool down to room temperature naturally, and...

Embodiment 2)

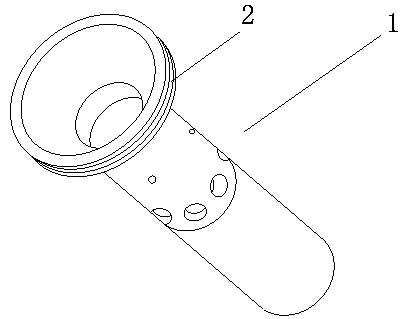

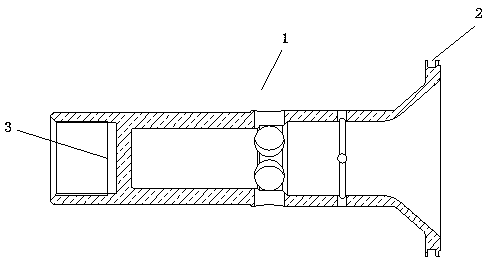

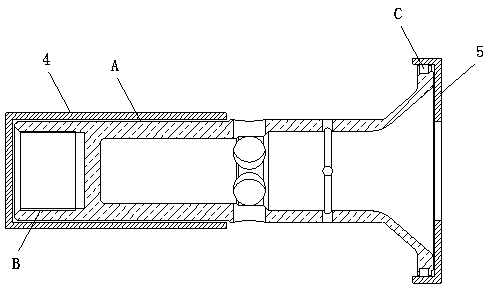

[0039] See Figure 1 to Figure 3 , The present invention has a brake jack 1, one end of the brake jack 1 has an internally threaded hole 3, and the other end has a seal groove 2, and the seal groove 2 is a circumferential seal groove structure. The brake jack 1 has an internally threaded hole 3 and one end is covered with a first protective sleeve 4 , and the brake jack 1 has a sealing groove 2 and one end is covered with a second protective sleeve 5 .

Embodiment 3)

[0041] See image 3 , the first protective cover 4 and the second protective cover 5 of the present invention are made of high-temperature-resistant metal materials, the first protective cover 4 and the second protective cover 5 are transitionally fitted with the two ends of the brake ejector rod 1, A in the figure , B, and C parts are non-nitrided regions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com