A vacuum pre-pressing dehydration system and implementation method for superfine tailings filling tube bag

A vacuum and thin tail technology, which is applied in the field of engineering pipe bag dam construction, can solve the problems of lack of dam construction technology, limited moisture content reduction, high material cost, etc. It is simple and easy to achieve the degree of mechanization, high degree of mechanization, and saves materials cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

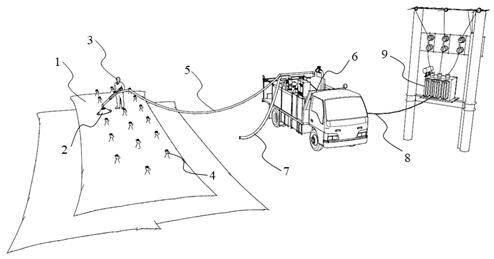

[0035] Such as image 3 As shown, a vacuum preloading system for ultra-fine tailings filling bags, including geotechnical tube bag 1, vacuum preloading handheld terminal module 2, construction personnel 3, geotechnical tube bag cuff module 4, vacuum rubber hose 5, mobile Vacuum preloading integrated equipment module 6, PVC drainage soft belt 7, high-voltage cable 8 and power supply module 9 and other main components; among them, the geotechnical pipe bag 1 is filled with ultra-fine tailings, and the geotechnical pipe bag cuff module 4 is set in the geotechnical pipe The top of the bag 1 is arranged in three rows staggered along the length direction; the construction personnel 3 stand on the surface of the geotechnical pipe bag 1, hold the vacuum preloading hand-held terminal module 2 and cover the pipe bag cuff module 4 with it; one end of the vacuum rubber h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com