A construction method of long spiral soil extraction and back-mixing cement-soil composite pile

A construction method and long-spiral technology, which are used in earthwork drilling, sheet pile wall, foundation structure engineering, etc. The effect of good pile quality and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

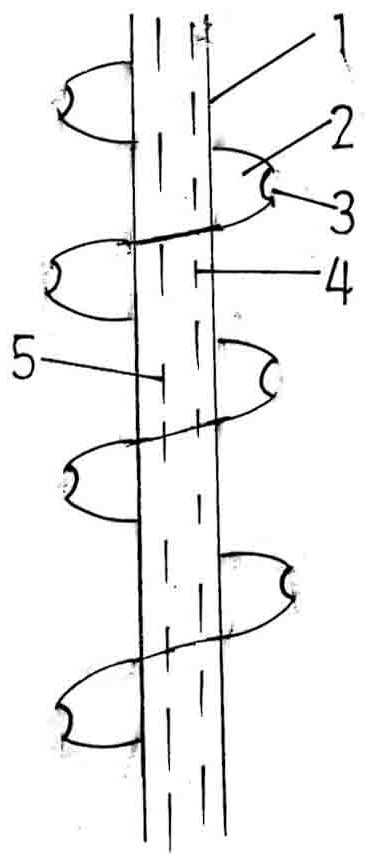

[0015] A construction method for a long helical soil fetching and backmixing cement-soil composite pile, using a long helical drill rod for construction, the long helical drill rod includes a long helical core pipe 1, and the outer periphery of the core pipe is provided with a long length to cut the soil The helical blades 2 are discontinuous, and there are several gaps 3 every week; the core pipe is equipped with double-core pipes 4 and 5, one for grouting and the other for air supply; the drill pipe rotates forward to drill , cutting the soil (you can inject cement slurry or other mixing materials at a certain depth); the drill pipe is reversed and lifted, and due to the gap in the helical blade, the drill pipe takes out part of the soil, and passes through the grouting channel while lifting the drill pipe Pressure grouting; after the drill pipe is lifted, drill forward again, and at the same time pour soil, sand and gravel into each layer of helical blades, and bring them in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com