Non-contact measuring method for upper and lower layer copper thickness applied to pcb multilayer board

A non-contact, multi-layer board technology, applied in the field of measurement, can solve the problems of inability to measure the structure of multi-layer films, damage to the film body, and non-transparency of metal films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The features and technical contents of the relevant patent applications of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings.

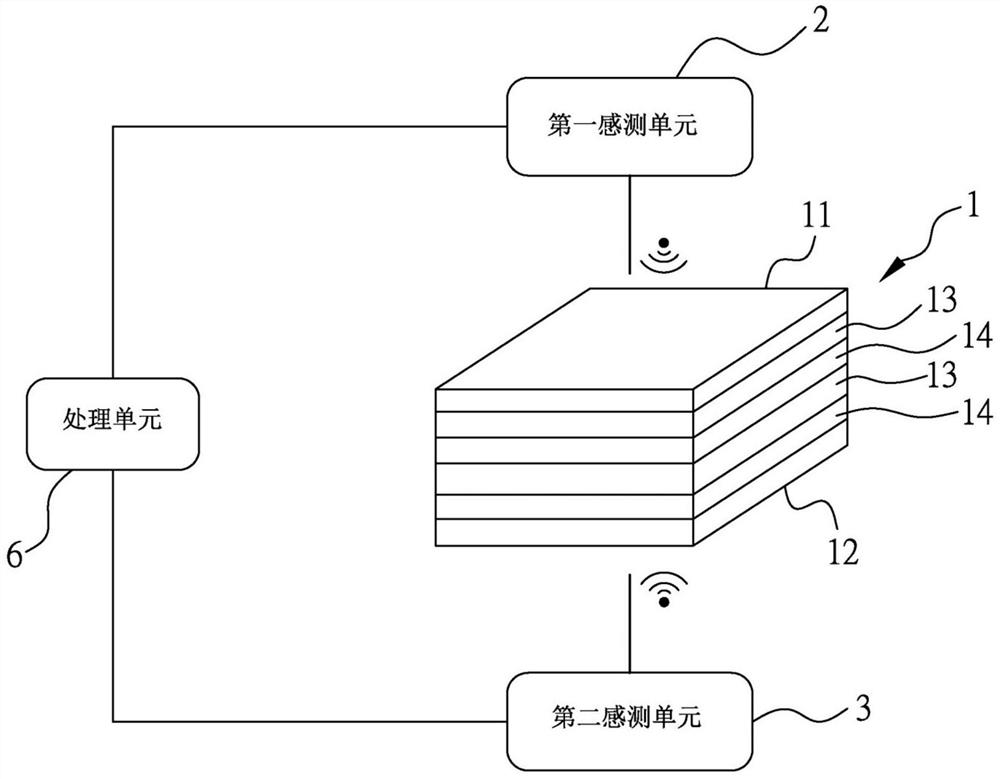

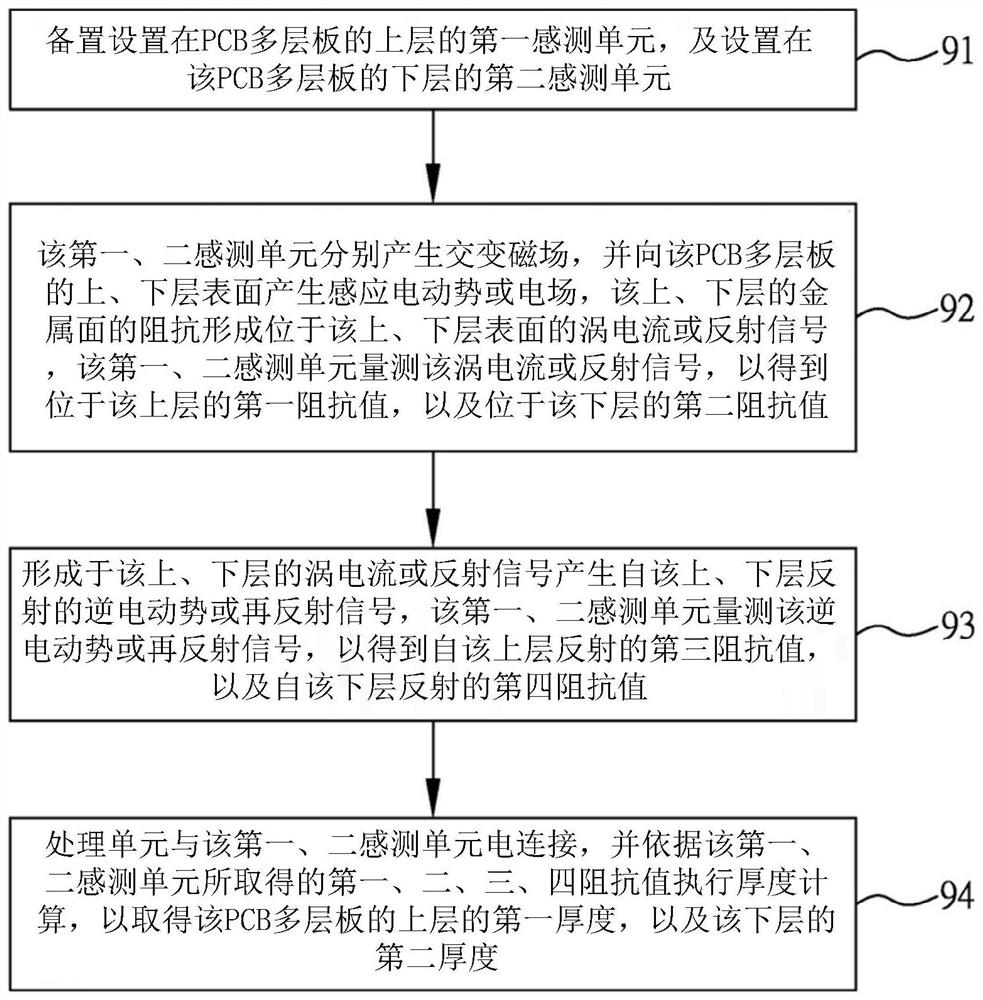

[0026] refer to figure 1 , 2 , which is a preferred embodiment of the non-contact method for measuring the copper thickness of the upper and lower layers of the PCB (Printed Circuit Board) multilayer board of the present invention, which includes the following steps.

[0027] First, proceed to step 91 , prepare the first sensing unit 2 disposed on the upper layer 11 of the PCB multilayer board 1 , and the second sensing unit 3 disposed on the lower layer 12 of the PCB multilayer board 1 . The measurement object of the measurement method of the present invention may be a PCB multilayer board 1 structure in which various surface coating materials are metal.

[0028] Here, the number of layers of the PCB multilayer board 1 is between 2 and 16 layers, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com