A kind of preparation method of electromagnetic wave shielding composite material

A composite material and electromagnetic wave technology, which is applied in the field of preparation of electromagnetic wave shielding composite materials, can solve problems such as unfavorable filling of composite shielding materials by metal fibers, and achieve the effects of strong operability, high electrical conductivity and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

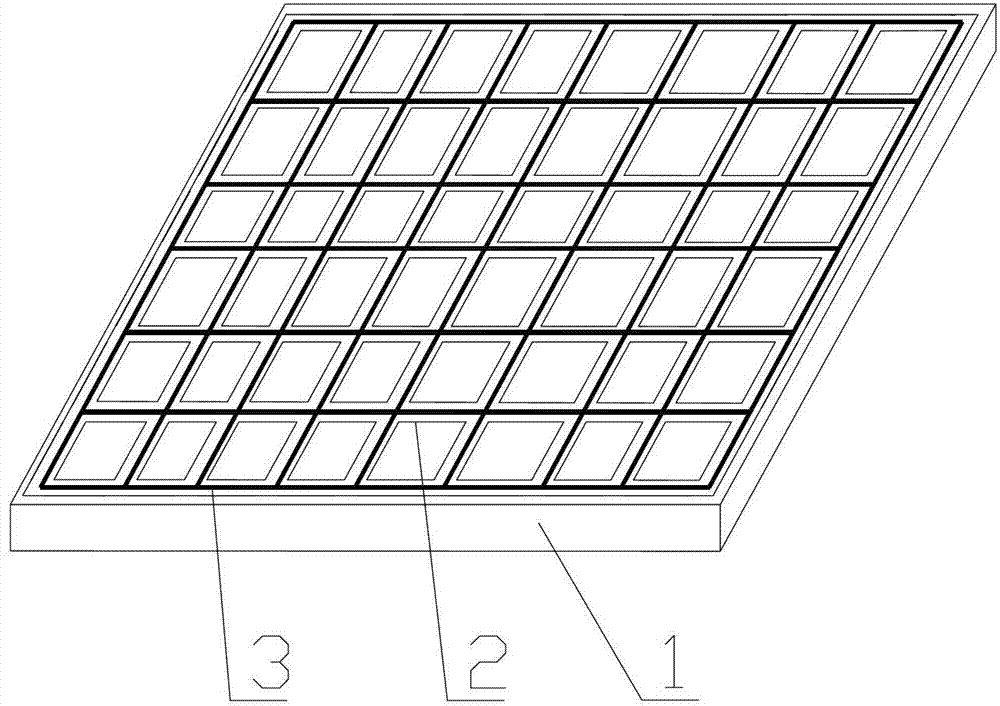

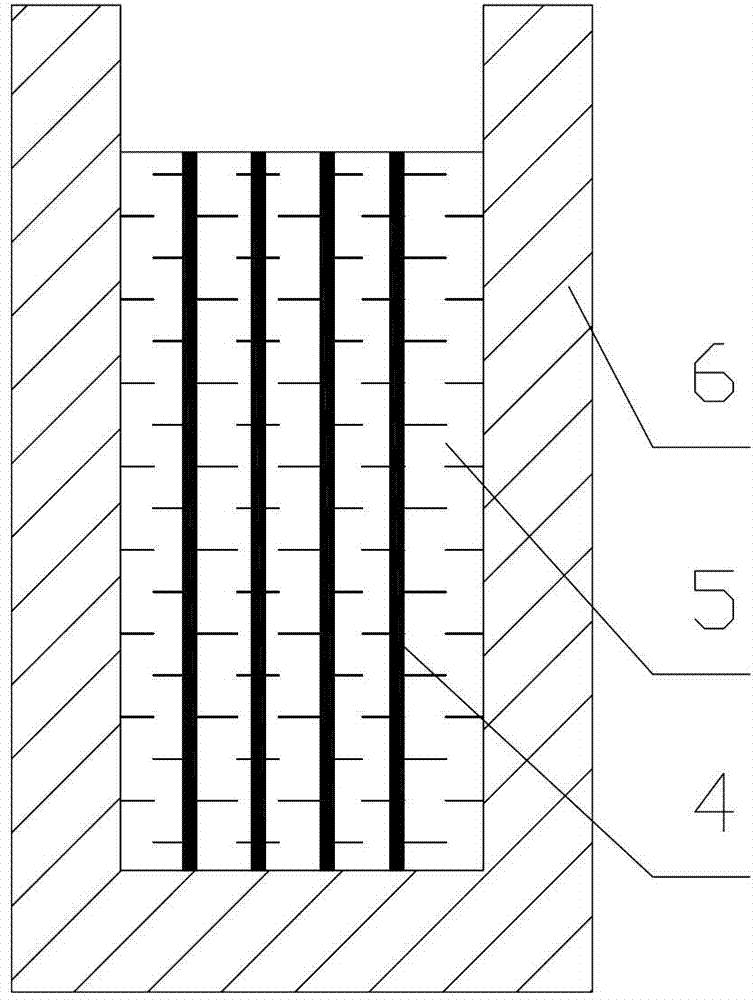

[0029] Such as figure 1 and figure 2 As shown, the preparation method of the electromagnetic wave shielding composite material of this embodiment includes the following steps:

[0030] Step 1. Etching 9 transverse grooves and 9 longitudinal grooves equidistantly on the surface of the ceramic plate 1 by using a dry etching process, the 9 transverse grooves and 9 longitudinal grooves are interlaced to form a network groove 2 , the groove depth of the mesh groove 2 is 90 μm;

[0031] Step 2: Use a stretcher to stretch the metal fiber 3 with a diameter of 8 μm to the designed length, and then place the stretched metal fiber 3 in the mesh groove 2, each transverse groove and each longitudinal groove 10 metal fibers 3 are placed inside; the metal fibers 3 are stainless steel fibers;

[0032] Step 3. Put the ceramic plate 1 with the metal fiber 3 placed in the step 2 into a vacuum sintering furnace, and the vacuum degree is 1×10 -3 Pa, the temperature is sintering under the cond...

Embodiment 2

[0037] Such as figure 1 and figure 2 As shown, the preparation method of the electromagnetic wave shielding composite material of this embodiment includes the following steps:

[0038] Step 1. Etching 5 transverse grooves and 5 longitudinal grooves equidistantly on the surface of the ceramic plate 1 by using a dry etching process, the 5 transverse grooves and 5 longitudinal grooves are interlaced to form a network groove 2 , the groove depth of the mesh groove 2 is 200 μm;

[0039]Step 2: Use a stretcher to stretch the metal fiber 3 with a diameter of 100 μm to the designed length, and then place the stretched metal fiber 3 in the mesh groove 2, each transverse groove and each longitudinal groove Two metal fibers 3 are placed inside; the metal fibers 3 are stainless steel fibers;

[0040] Step 3. Put the ceramic plate 1 with the metal fiber 3 placed in the step 2 into a vacuum sintering furnace, and the vacuum degree is 1×10 -2 Pa, the temperature is sintering under the c...

Embodiment 3

[0045] Such as figure 1 with figure 2 As shown, the preparation method of the electromagnetic wave shielding composite material of this embodiment includes the following steps:

[0046] Step 1. Etch 12 transverse grooves and 12 longitudinal grooves equidistantly on the surface of the ceramic plate 1 by using a wet etching process, and the 12 transverse grooves and 12 longitudinal grooves are interlaced to form a mesh groove 2 , the groove depth of the mesh groove 2 is 10 μm;

[0047] Step 2: Use a stretcher to stretch the metal fiber 3 with a diameter of 8 μm to the designed length, and then place the stretched metal fiber 3 in the mesh groove 2, each transverse groove and each longitudinal groove One metal fiber 3 is placed inside; the metal fiber 3 is aluminum fiber;

[0048] Step 3. Put the ceramic plate 1 with the metal fiber 3 placed in the step 2 into a vacuum sintering furnace, and the vacuum degree is 1×10 -3 Pa, the temperature is sintered under the condition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com