A flake of α‑al 2 o 3 Powder and its preparation method

A powder and flake technology, which is applied in the field of flake α-Al2O3 powder and its preparation, can solve the problems of uneven distribution of ingredients, difficulty in preparing alumina powder, etc., and achieve repeated utilization, low equipment requirements, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A flake α-Al 2 o 3 The preparation method of powder, it comprises the following steps:

[0029] (1) Prepare raw materials: weigh 42g aluminum sulfate octadecahydrate, 8.60g sodium sulfate, 10.53g potassium sulfate, 0.032g titanyl sulfate, 0.15g sodium phosphate and 42.00g potassium hydroxide;

[0030] (2) Mix each raw material with absolute ethanol (the amount of absolute ethanol added is 1.5 times the total mass of the raw material) by ball milling, and after drying, perform calcination at 1100°C for a holding time of 5 hours, then cool naturally to room temperature, and calcine The product is flaky α-Al 2 o 3 Powder and molten salt mixture;

[0031] (3) Wash the calcined product obtained in step (2) with deionized water to remove water-soluble salts in the product, then filter and dry to obtain flaky α-Al 2 o 3 Powder.

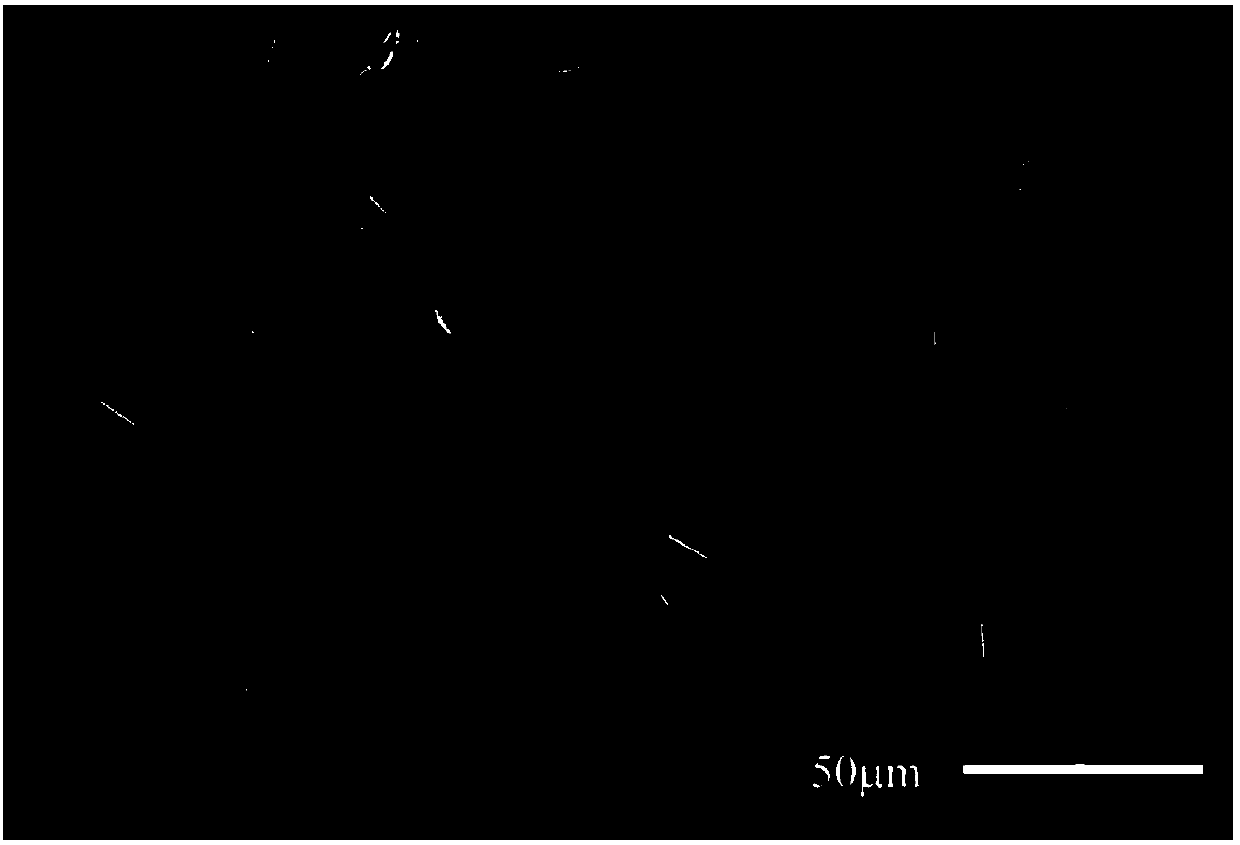

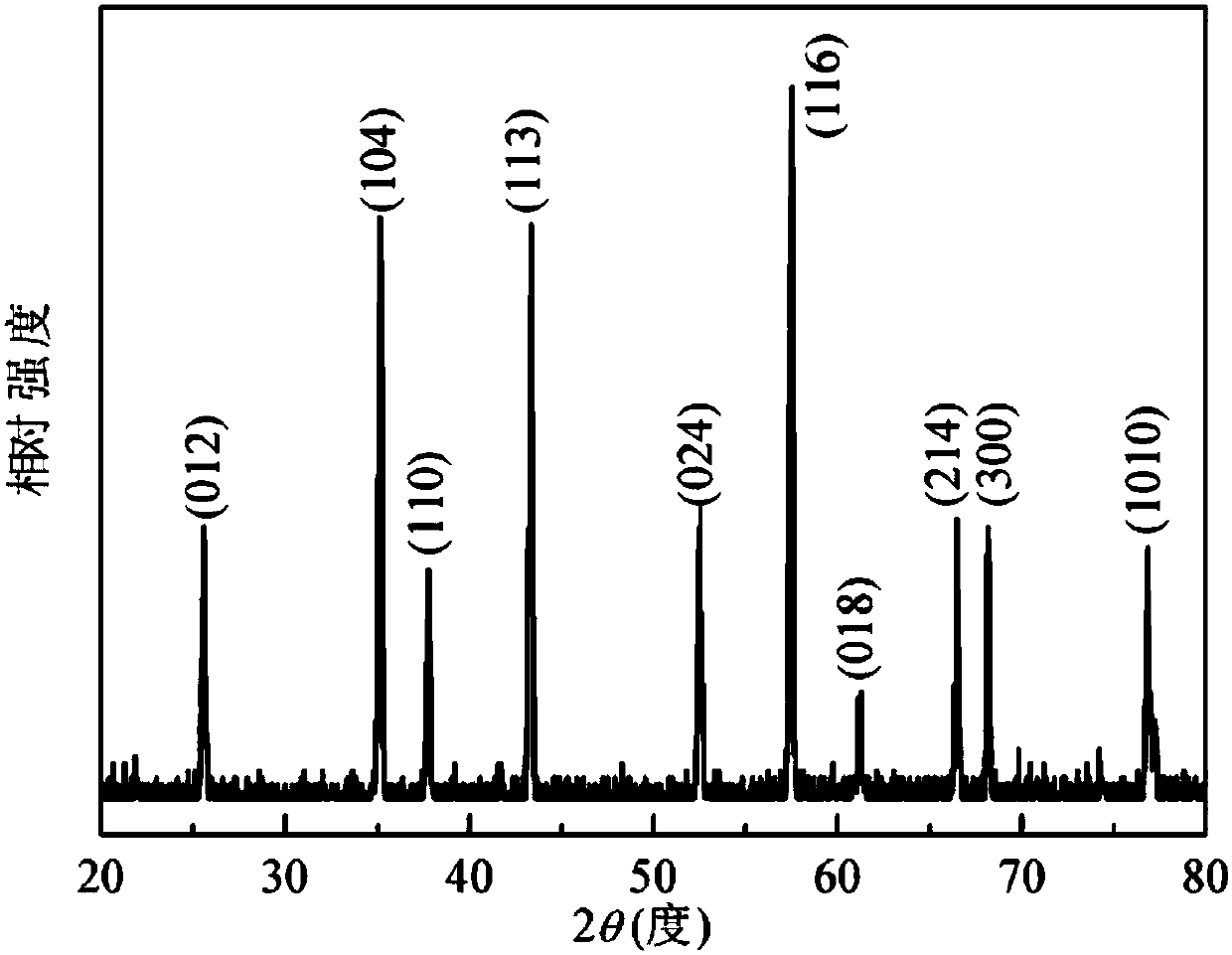

[0032] Such as figure 1 As shown, the flaky α-Al prepared in this example 2 o 3 The average particle size of the powder is 18μm and the dis...

Embodiment 2

[0034] A flake α-Al 2 o 3 The preparation method of powder, it comprises the following steps:

[0035] (1) Prepare raw materials: weigh 42g aluminum sulfate octadecahydrate, 8.60g sodium sulfate, 10.53g potassium sulfate, 0.032g titanyl sulfate and 0.15g sodium phosphate;

[0036] (2) Mix each raw material with absolute ethanol (the amount of absolute ethanol added is 1.5 times the total mass of the raw material) by ball milling, and after drying, perform calcination at 1100°C for a holding time of 5 hours, then cool naturally to room temperature, and calcine The product is flaky α-Al 2 o 3 Powder and molten salt mixture;

[0037] (3) Wash the calcined product obtained in step (2) with deionized water to remove water-soluble salts in the product, then filter and dry to obtain flaky α-Al 2 o 3 Powder.

[0038] The flaky α-Al prepared in this example 2 o 3 The average particle size of the powder is 15.9 μm, and the thickness is 0.10 μm-0.40 μm.

Embodiment 3

[0040] A flake α-Al 2 o 3 The preparation method of powder, it comprises the following steps:

[0041] (1) Prepare raw materials: weigh 42g aluminum sulfate octadecahydrate, 8.60g sodium sulfate, 10.53g potassium sulfate, 0.032g titanyl sulfate, 0.15g sodium phosphate and 2.50g sodium carbonate;

[0042] (2) Mix each raw material with absolute ethanol (the amount of absolute ethanol added is 1.5 times the total mass of the raw material) by ball milling, and after drying, perform calcination at 1100°C for a holding time of 5 hours, then cool naturally to room temperature, and calcine The product is flaky α-Al 2 o 3 Powder and molten salt mixture;

[0043] (3) Wash the calcined product obtained in step (2) with deionized water to remove water-soluble salts in the product, then filter and dry to obtain flaky α-Al 2 o 3 Powder.

[0044] The flaky α-Al prepared in this example 2 o 3 The average particle size of the powder is 11.4 μm, and the thickness is 0.15 μm-0.35 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com