Puzzle robot system for practical training and assessment method thereof

A robot system and robot technology, applied in the field of robot systems for practical training, can solve problems such as training that cannot be formed into a system, achieve the effect of simple planning and programming ability, and improve the understanding of operating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

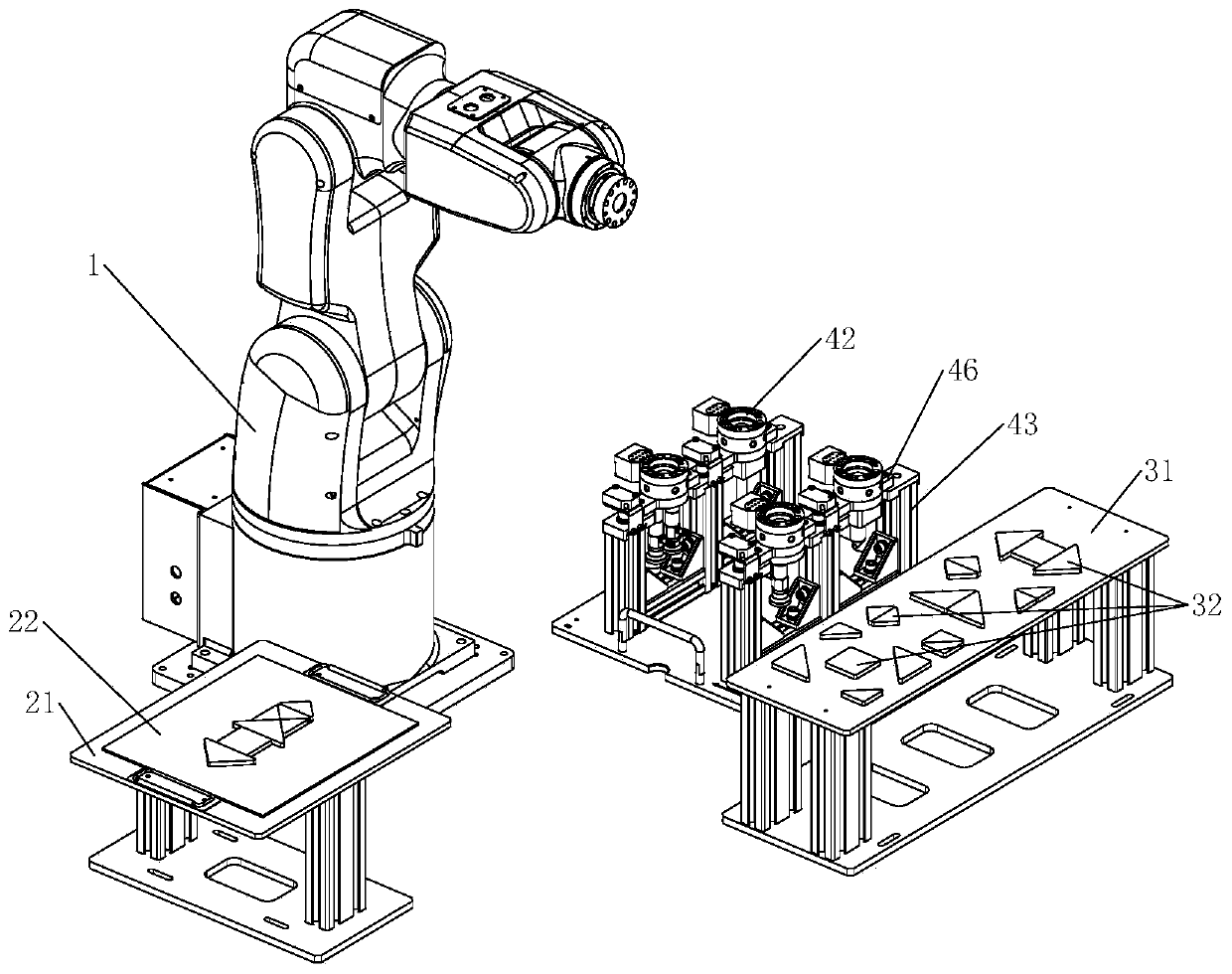

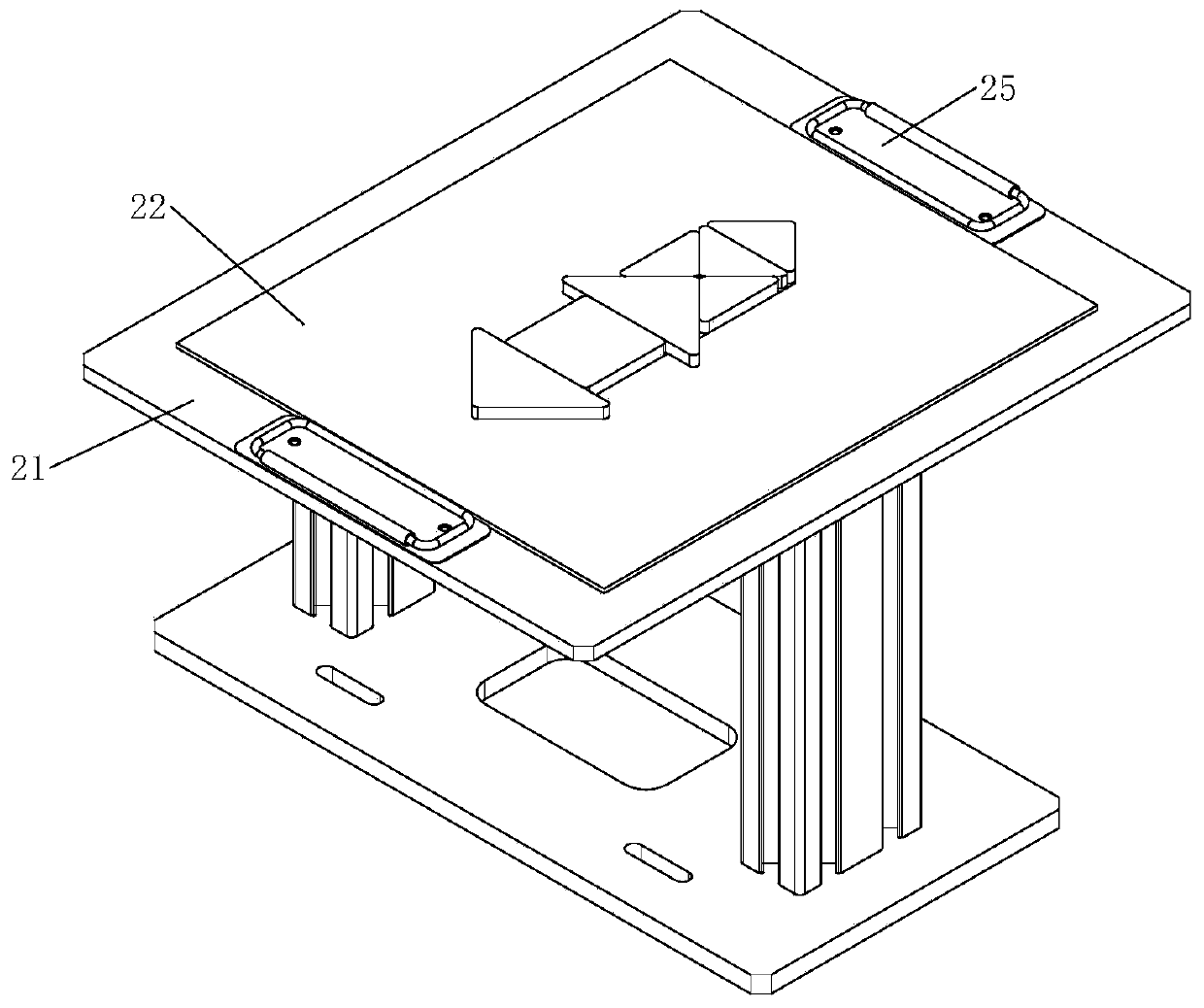

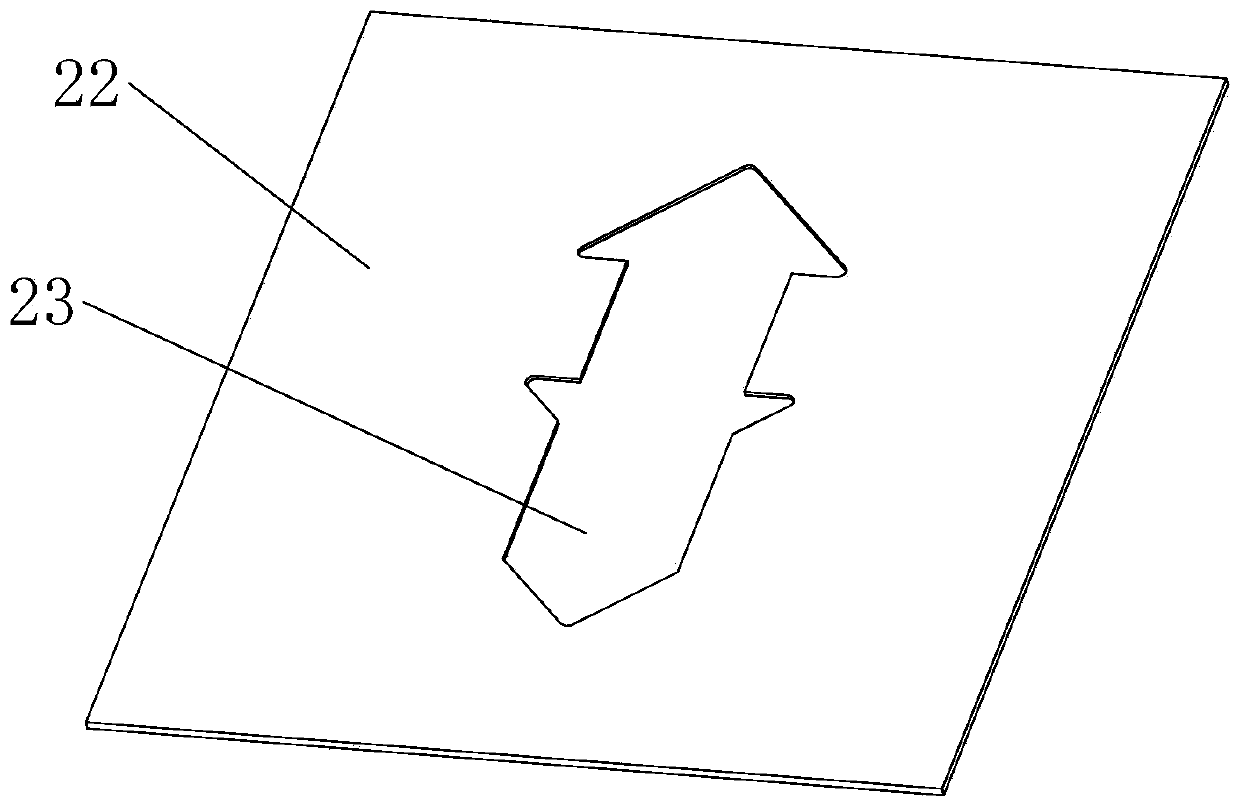

[0036] Such as Figure 1 to Figure 5 As shown, the jigsaw puzzle robot system for training includes a teaching pendant and robot 1. Robot 1 is a six-axis industrial robot 1 or a seven-axis industrial robot 1 with external axes. The end of robot 1 is equipped with a male quick-change tool tray, as shown The teaching device is connected with the robot 1; it also includes a jigsaw block 32, the jigsaw block 32 includes blocks of various geometric shapes, and each shape block is no less than one specification; the block frame, the jigsaw block 32 Placed on the block frame; the jigsaw fixture, the jigsaw jig is equipped with a female quick-change tool tray 42, and the jigsaw jig is used to grab the jigsaw block 32; the tool rack, the jigsaw jig is movably inserted on the tool rack; the jigsaw workbench 21, The workbench 21 is used for placing jigsaw puzzle pieces 32 for splicing.

[0037] Specifically, the geometric shape of the jigsaw block 32 is a plane geometric figure, includi...

Embodiment 2

[0045]The assessment method of the jigsaw robot for training is conducted through the jigsaw robot system for training. The assessment method of the jigsaw robot for training includes the following steps:

[0046] S110. Control the robot 1 to move to the jigsaw jig through the teaching pendant, and install the jigsaw jig, and switch the coordinate system to the jigsaw coordinate system on the teaching pendant;

[0047] S120. Control the robot 1 through the teaching pendant to move the jigsaw jigsaw to the top of the block frame, make the jigsaw jigsaw contact with the jigsaw puzzle block 32 with a suitable posture, record the current pose in the program of the teaching pendant, and at the same time Instructions for opening the digital output signal state of the solenoid valve are inserted in the program, so that the jigsaw fixture absorbs the jigsaw puzzle block 32;

[0048] S130. Use the teaching pendant to control the robot 1 to select a number of path points in the space be...

Embodiment 3

[0054] The assessment method of the jigsaw robot for training is conducted through the jigsaw robot system for training. The assessment method of the jigsaw robot for training includes the following steps:

[0055] S210, sequentially setting and installing the jigsaw fixture and the jigsaw coordinate system in the off-line programming and simulation software;

[0056] S220. Set the starting point and the end point of the puzzle block 32 in the off-line programming and simulation software, and set an instruction for opening or closing the digital output signal state of the solenoid valve;

[0057] S230, setting the spatial path between the starting point and the end point of the jigsaw puzzle block 32 in the off-line programming and simulation software;

[0058] S240. Generate a jigsaw puzzle program executable by the robot 1 in the off-line programming and simulation software, and send the jigsaw puzzle program to the teaching pendant, load and run the jigsaw puzzle program on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com