Ceramic PCB disc type brushless excitation motor

A technology of excitation motor and ceramics, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of not being able to use the motor, reduce the volume, etc., achieve the elimination of cogging torque and core loss, and reduce the thickness, size and positioning precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

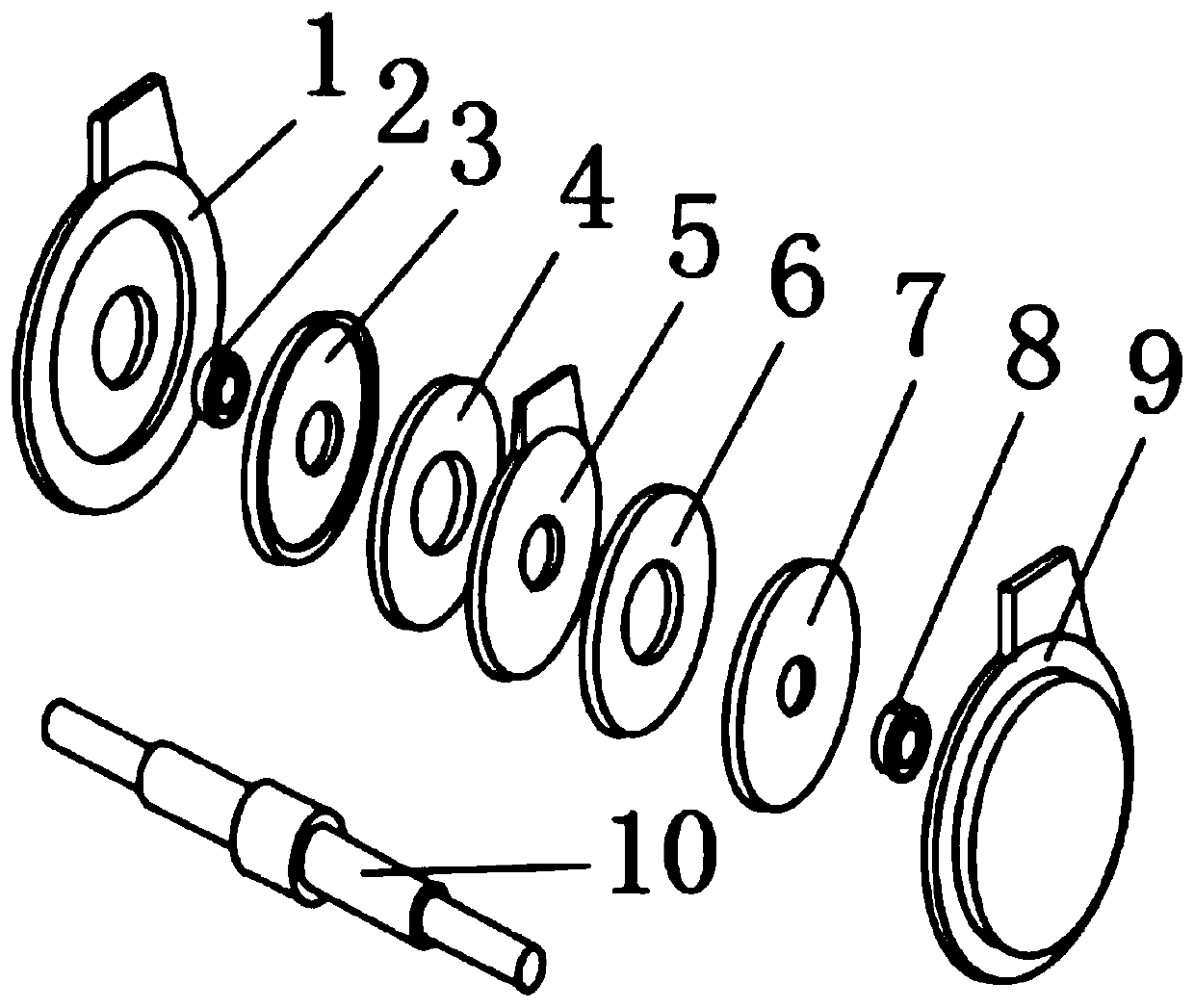

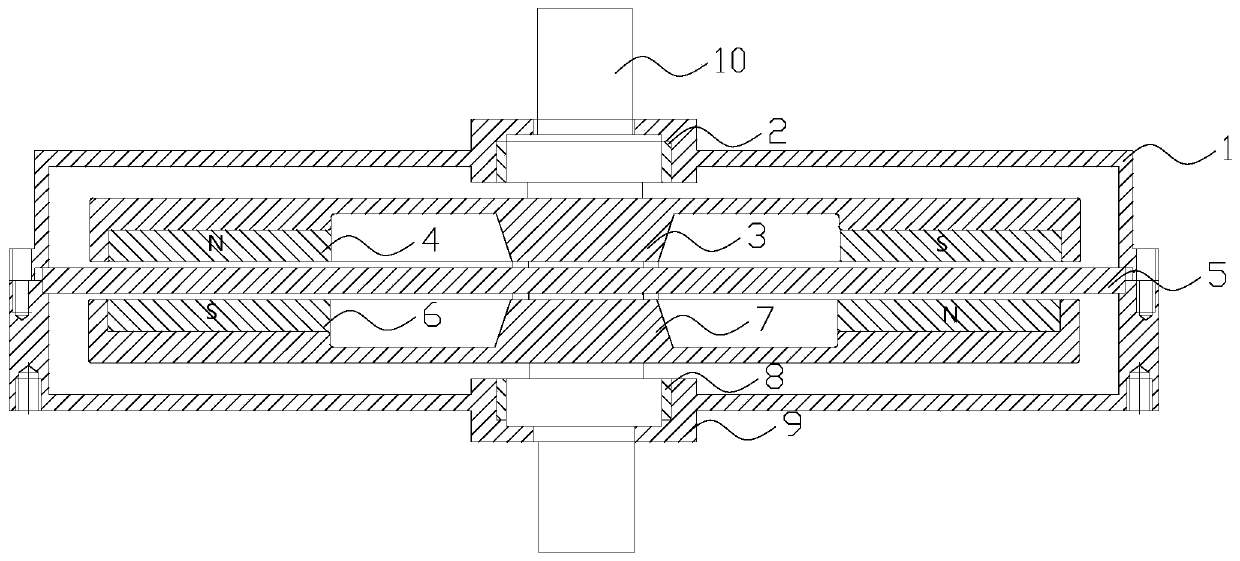

[0031] like Figure 1 to Figure 4 As shown, the ceramic PCB disc brushless excitation motor includes a front cover sequentially arranged on the central shaft, a first group of axial magnets (first bearings, first magnetic steel, first permanent magnets), ceramic PCB windings, and a first set of axial magnets. A group of axial magnets (the second permanent magnet, the second magnetic steel, the second bearing), the back cover; the above-mentioned parts are all provided with connecting holes at the center, and the central shaft is sheathed on the above-mentioned parts.

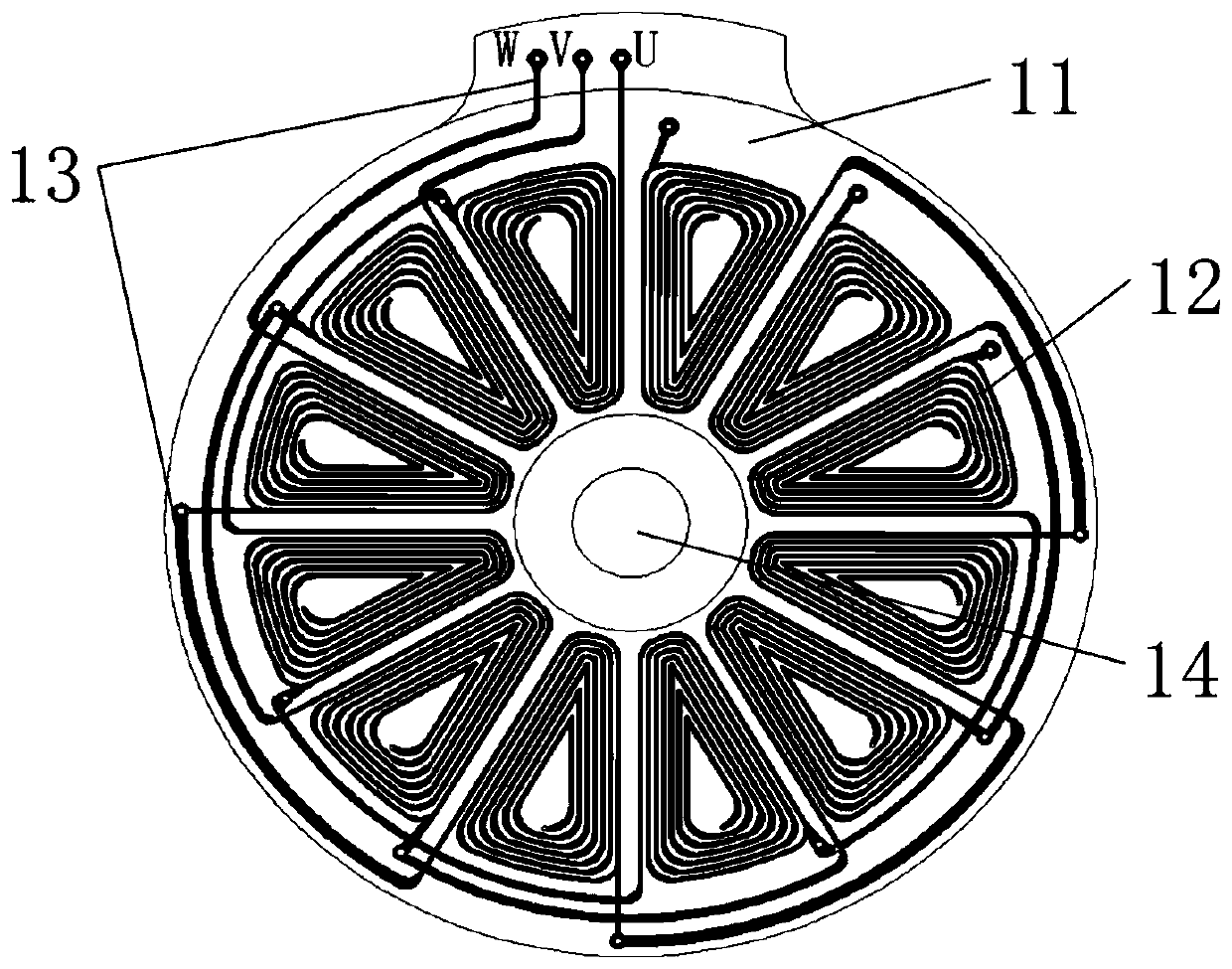

[0032] The ceramic PCB winding includes a layer of ceramic PCB substrate, the specific number can be superimposed according to actual needs, and the winding fixed on the ceramic PCB substrate, the winding is distributed in a circular array with a central axis hole on the ceramic PCB substrate.

[0033] The use of ceramic PCB winding motors eliminates the problems of motor function and life caused by the aging, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com