AC servo system mechanical resonance suppression method and system

A mechanical resonance and AC servo technology, applied in the direction of motor vibration suppression control, observer control, etc., can solve the problems that cannot be changed at will, the degree of improvement is limited, and the viscosity coefficient of the motor and transmission device is difficult to improve, so as to achieve simple configuration, Strong anti-load disturbance and high steady-state accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

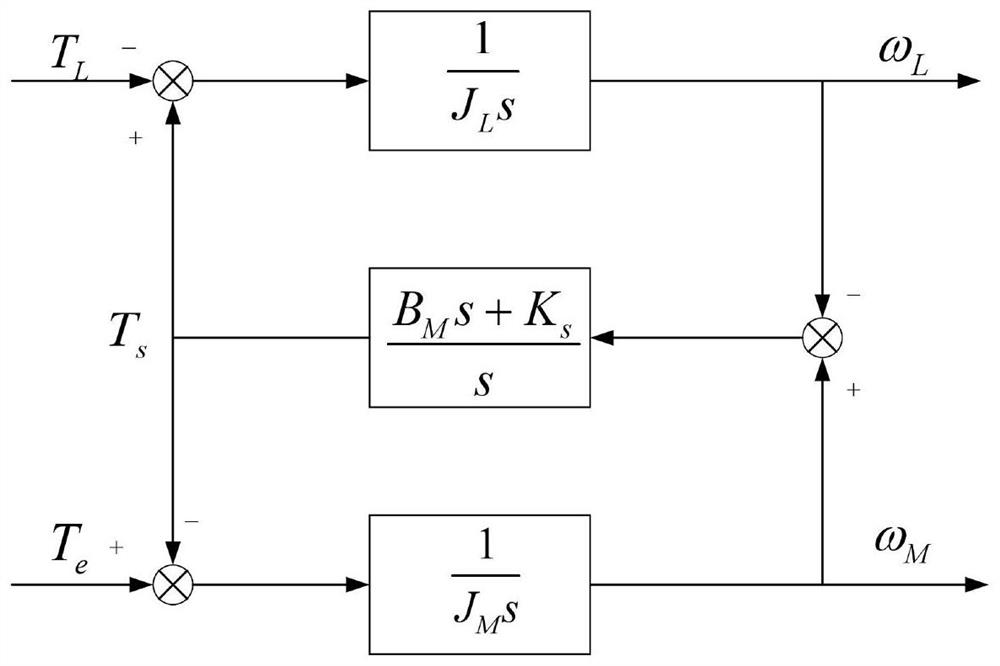

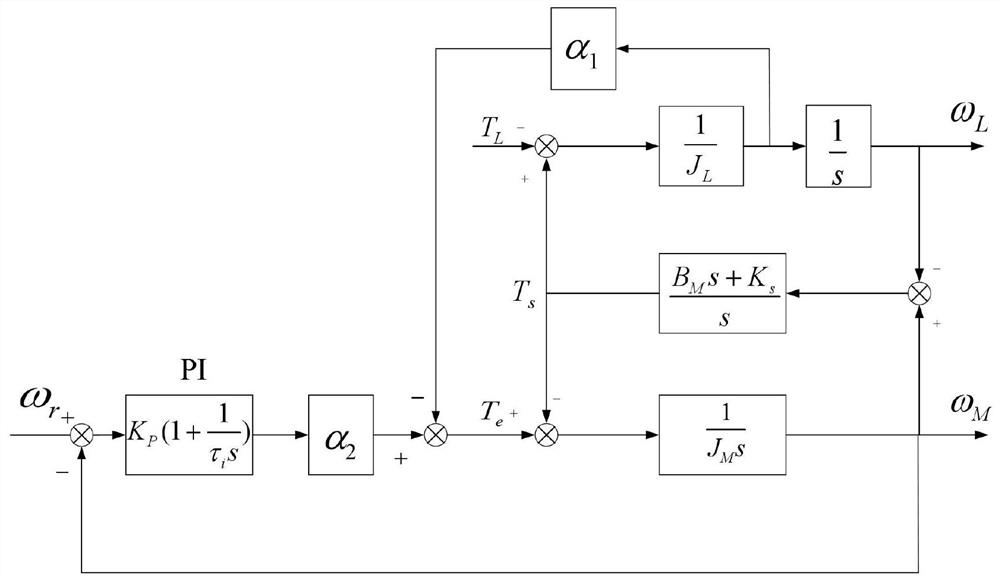

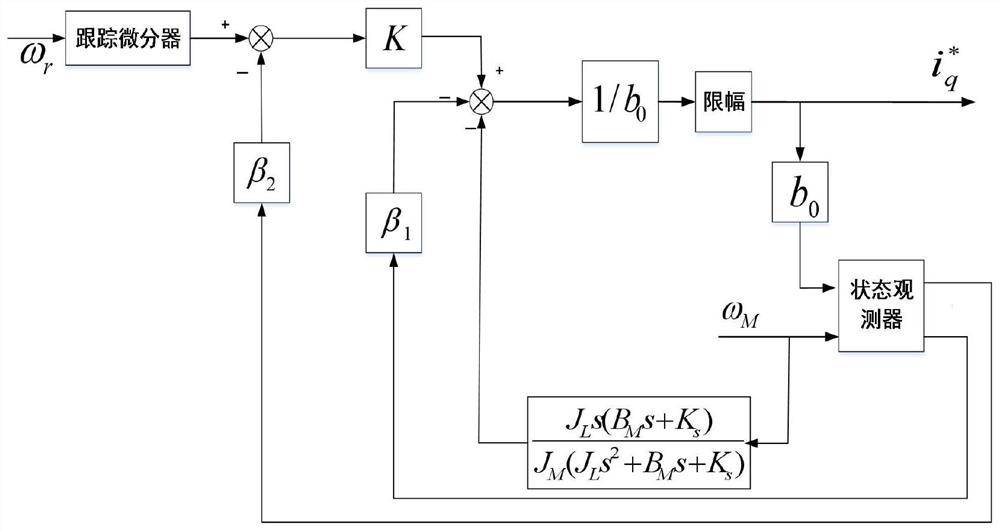

[0057] An embodiment of the present invention provides a method for suppressing mechanical resonance of an AC servo system, including the following steps: S1, establishing a dual-inertia transmission device model; S2, adding an ADRC controller structure to the dual-inertia transmission device model; S3, adding the On the basis of the model of ADRC controller structure described above, load acceleration feedback compensation is added. In the prior art, mechanical resonance suppression can be divided into the following two categories: one is active suppression methods, such as based on PID structure pole configuration, based on observer observation of load speed, load torque, etc., based on model reference adaptive, fuzzy control, Genetic algorithm and other advanced control algorithms, literature (Min Yilong, Wang Ganquan. Resonance Suppression of Three-axis Stabilized Satellite Scanning Mirror Servo System[J]. Control Theory and Application, 2018, 35(9): 1250-1259. DOI: 10.7641...

Embodiment 2

[0106] An embodiment of the present invention provides a mechanical resonance suppression system for an AC servo system, including a dual-inertia transmission device model, an ADRC controller structure added to the dual-inertia transmission device model, and an ADRC controller structure added after the ADRC controller structure is added. Load acceleration feedback structure. Preferably, the dual inertia transmission device model includes a motor, a transmission device and a load, and the transmission device transmits the motion and power of the motor to the load, so as to control the motion of the load to meet the requirements of the system. This embodiment is the same as the first embodiment above, so it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com